Zero-VOC radiation curable/moisture curing resin and preparation method thereof

A radiation curing and moisture curing technology, applied in the field of coatings, can solve problems such as inability to prepare coatings, and achieve the effects of widening the scope of use, low preparation costs, and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

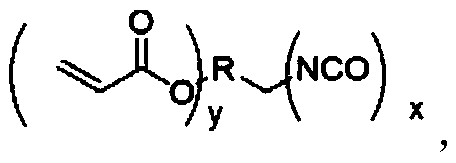

Method used

Image

Examples

Embodiment 1

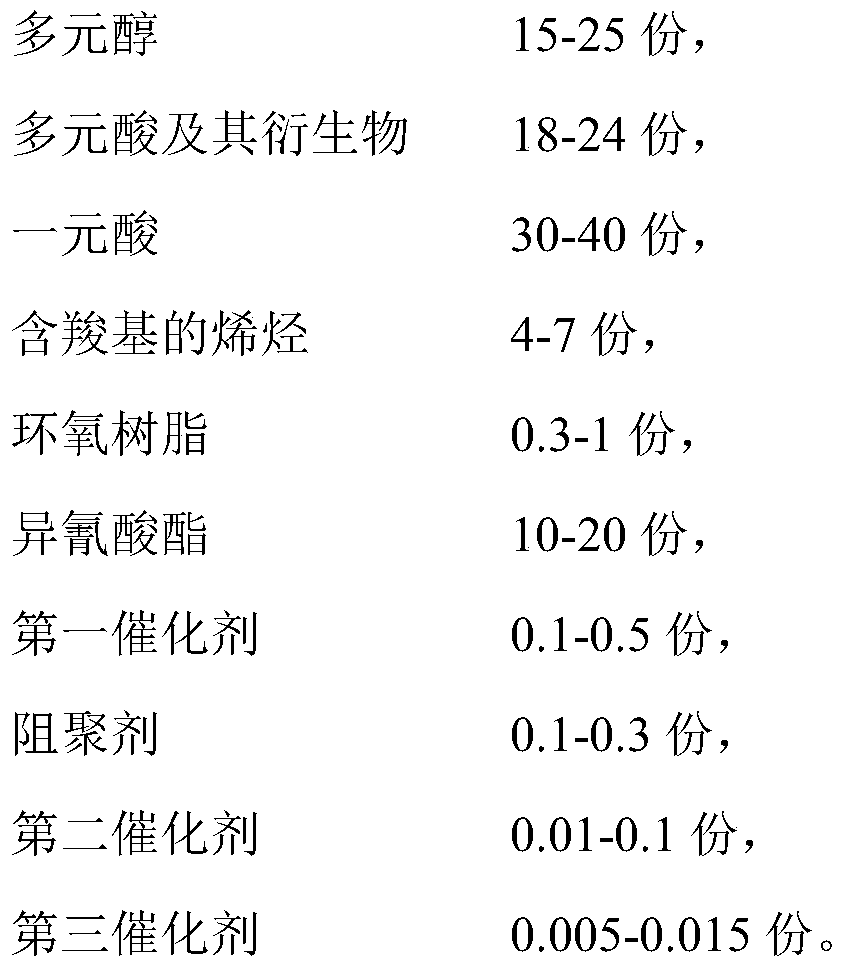

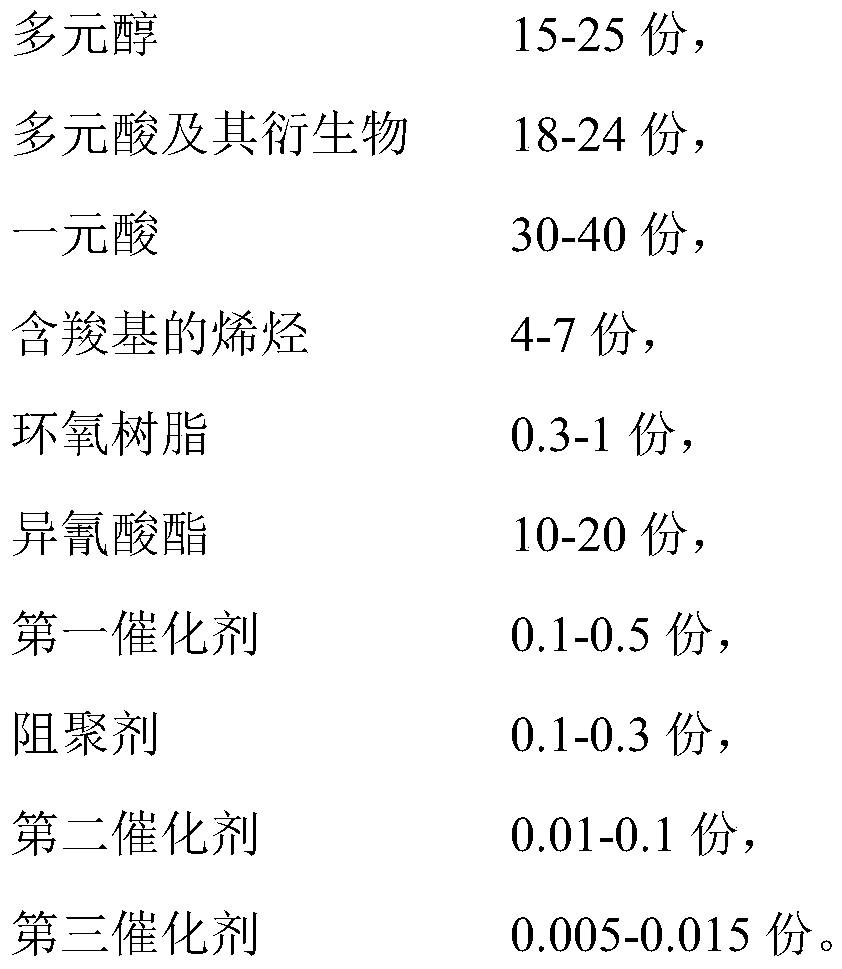

[0060] A zero-VOC radiation-curable / moisture-curable resin, comprising the following raw materials in parts by weight:

[0061]

[0062]

[0063] The preparation method of zero-VOC radiation-curable / moisture-curable resin comprises the following steps:

[0064] 1) Add polyhydric alcohols, polyacids and their derivatives into a reaction kettle with mechanical stirring, nitrogen flow, and rectification column, raise the temperature to 190 ° C, keep it warm for 1 hour, then add monobasic acid dropwise, and continue to press 10 degrees / The temperature was raised to 220°C at a rate of 1 hour, and the temperature was kept for 5 hours to obtain a branched polyester;

[0065] 2) The branched polyester obtained in step 1) is transferred to a reactor with ventilating and condensing reflux devices, wherein the water separator has been filled with toluene, and the carboxyl-containing olefin and the first catalyst are added, and the temperature is raised to 90 ℃, put in the air to...

Embodiment 2

[0069] A zero-VOC radiation-curable / moisture-curable resin, comprising the following raw materials in parts by weight:

[0070]

[0071]

[0072] The preparation method of zero-VOC radiation-curable / moisture-curable resin comprises the following steps:

[0073] 1) Add polyhydric alcohols, polybasic acids and their derivatives into a reaction kettle with mechanical stirring, nitrogen flow, and rectification column, raise the temperature to 150°C, keep it warm for 2 hours, then add monobasic acid dropwise, and continue to press 10 degrees / The temperature is raised to 200°C at a rate of 1 hour, and the temperature is kept for 5 hours to obtain a branched polyester;

[0074] 2) The branched polyester obtained in step 1) is transferred to a reactor with ventilating and condensing reflux devices, wherein the water separator has been filled with toluene, and the carboxyl-containing olefin and the first catalyst are added, and the temperature is raised to 110 ℃, put in the air...

Embodiment 3

[0078] A zero-VOC radiation-curable / moisture-curable resin, comprising the following raw materials in parts by weight:

[0079]

[0080]

[0081] The preparation method of zero-VOC radiation-curable / moisture-curable resin comprises the following steps:

[0082] 1) Add polyhydric alcohols, polyacids and their derivatives into a reaction kettle with mechanical stirring, nitrogen flow, and rectification column, raise the temperature to 160°C, keep warm for 2 hours, then add monobasic acid dropwise, and continue to press 10°C / The temperature was raised to 190°C at a rate of 1 hour, and the temperature was kept for 6 hours to obtain a branched polyester;

[0083] 2) The branched polyester obtained in step 1) is transferred to a reactor with ventilating and condensing reflux devices, wherein the water separator has been filled with toluene, and the carboxyl-containing olefin and the first catalyst are added, and the temperature is raised to 110 ℃, put in the air to reflux, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com