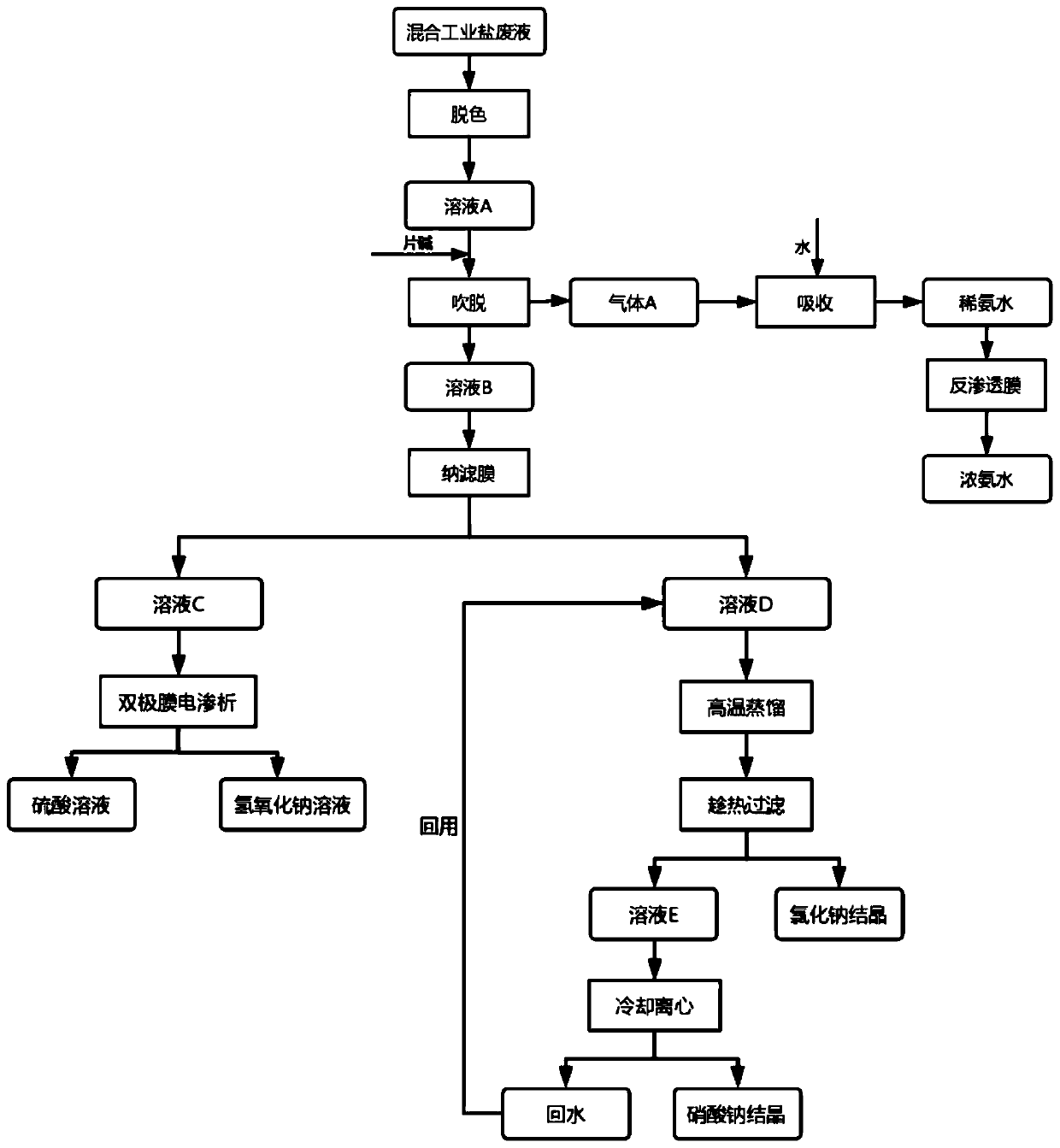

Method for using membrane technology for recycling mixed industrial salt waste solutions

A technology of industrial salt and membrane technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal chloride, etc., can solve the problems of complex equipment, high energy consumption, high risk factor, etc., and achieve good economic and environmental benefits, equipment Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 500mL of spray tower waste liquid from a chemical manufacturer (sulfate radical 100g / L, nitrate radical 80g / L, chloride ion 80g / L, ammonia nitrogen 80g / L), add decolorizer activated carbon 2.5g to the waste liquid, and stir for 2h , filtered to obtain solution A, the secondary waste activated carbon was regenerated through a high-temperature furnace, after adding caustic soda to adjust pH=7 in solution A, the solution obtained after blowing off by stripping tower and absorbing by spray tower passed through reverse osmosis membrane to obtain 291g 26.2% concentrated ammonia water and fresh water, the fresh water enters the water treatment system; the liquid after the stripping tower passes through the nanofiltration membrane to obtain solution C and solution D, and solution C can obtain 12.5% hydrogen after passing through the modified bipolar membrane Sodium oxide solution and 13.9% sulfuric acid solution, solution D was concentrated under high temperature at 95°C ...

Embodiment 2

[0029] Take 500mL of spray tower waste liquid from a chemical manufacturer (sulfate radical 100g / L, nitrate radical 80g / L, chloride ion 80g / L, ammonia nitrogen 80g / L), add decolorizer activated carbon 4g to the waste liquid, and stir for 2.5h , filtered to obtain solution A, the secondary waste activated carbon was regenerated through a high-temperature furnace, after adding caustic soda to adjust pH=8 in solution A, the solution obtained after blowing off by stripping tower and absorbing by spray tower passed through RO membrane to obtain 284g 26.8 % concentrated ammonia water and fresh water, and fresh water enters the water treatment system; the liquid after the stripping tower passes through the nanofiltration membrane to obtain solution C and solution D, and solution C can obtain 12.9% hydrogen oxidation after passing through the modified bipolar membrane Sodium solution and 14.1% sulfuric acid solution, solution D was concentrated under high temperature at 100°C and -0.03...

Embodiment 3

[0031] Get 500mL of spray tower waste liquid of certain chemical manufacturer (sulfate radical 100g / L, nitrate radical 80g / L, chloride ion 80g / L, ammonia nitrogen 80g / L), add decolorizer active carbon 5g in waste liquid, and stir 3h, Solution A is obtained by filtration, and the secondary waste activated carbon is regenerated through a high-temperature furnace. After adding caustic soda to the solution A to adjust the pH=9, the solution obtained after blowing off the stripping tower and absorbing the spray tower passes through the reverse osmosis membrane to obtain 281g 27.1 % concentrated ammonia water and fresh water, fresh water enters the water treatment system; the liquid after the stripping tower passes through the nanofiltration membrane to obtain solution C and solution D, and solution C can obtain 12.6% hydrogen oxidation after passing through the modified bipolar membrane Sodium solution and 14.2% sulfuric acid solution, solution D was concentrated under high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com