Method for treating pickling wastewater and recovering byproducts through reduced pressure and low temperature catalytic fractionation

A technology of pickling wastewater and low-temperature catalysis, which is applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of environmental pollution and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and examples, but no limitation is made hereto.

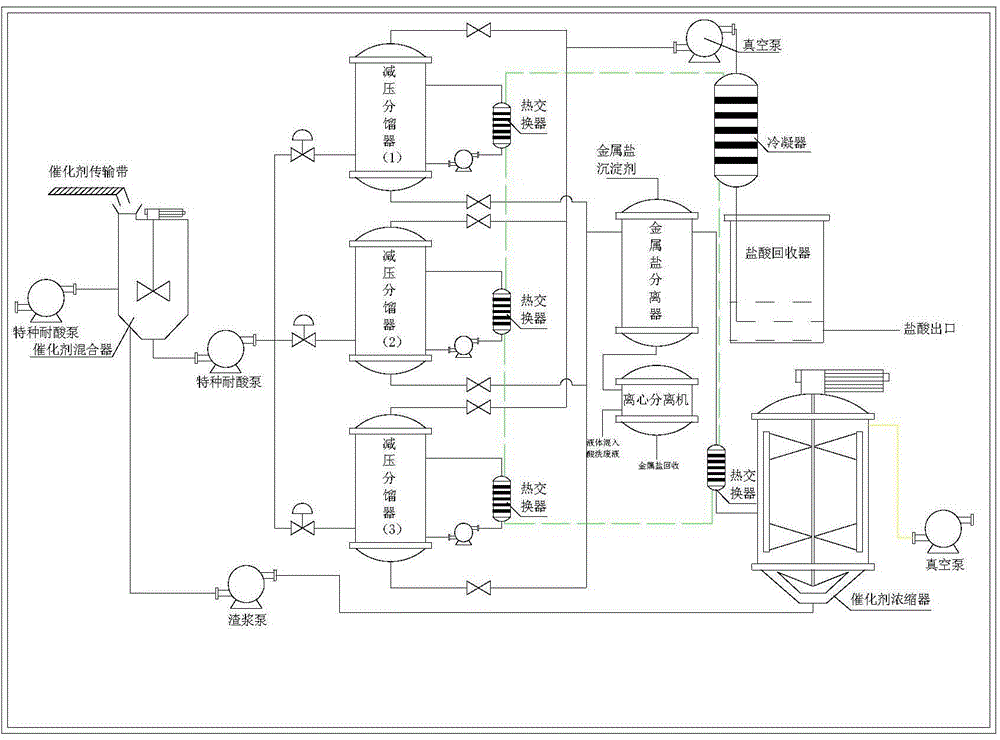

[0028] As shown in Fig. 1, the process of the present invention includes preparation (catalyst mixing), low-pressure fractionation, solid-liquid separation, metal salt separation, catalyst concentration, regenerated acid absorption, catalyst reflux and other operations.

[0029] The technical process of the present invention is to fully mix the multi-effect catalyst with the pickling waste liquid at a concentration of 35% to 48% and pour it into a low-pressure fractionator, and the mixed liquid is injected into a high-efficiency heat exchanger from the bottom of the low-pressure fractionator by an acid-resistant pump for forced circulation heating , the heated mixed liquid is sprayed from the top of the high-efficiency heat exchanger into the low-pressure fractionator, and the gas enters the condensing heat exchanger under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com