A kind of nerve conduit support and its preparation method and application

A nerve conduit and graphene technology, applied in the field of biomedical materials, can solve problems such as lack of biological activity, lack of good guidance for nerve regeneration, and inability to repair long-distance nerve defects, achieving good biocompatibility and simple preparation method. Easy operation, safe and reliable effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

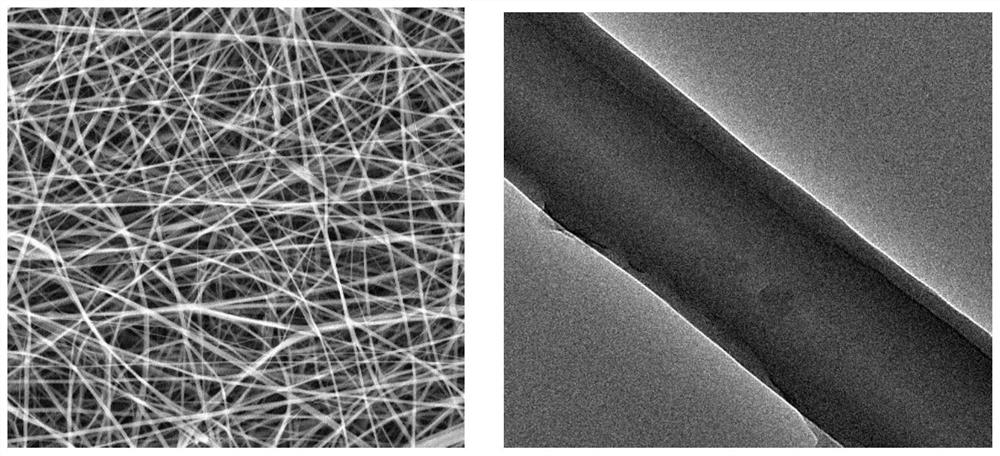

[0039] (1) Dissolve 10g of gelatin and 4g of PLA in 10ml of hexafluoroisopropanol, and keep stirring until completely dissolved to obtain a spinning solution with a concentration of 10% (mass volume ratio); add 3mg of redox graphene to the above Ultrasonic dispersion in the spinning solution to obtain the spinning solution of graphene / gelatin / PLA, spinning conditions: voltage 13 kV, receiving distance 10cm, spinning rate 1.4ml / h, electrospinning to obtain nanofiber membrane, placed in Store in a vacuum oven for later use.

[0040] (2) Shred the nanofiber membrane obtained in step (1), weigh 2g of the fragments and add them to a beaker filled with 10ml of tert-butanol, and use a high-speed homogenizer to carry out homogenization and pulverization of the nanofiber membrane fragments, Until the fiber membrane is completely broken and evenly dispersed in the tert-butanol solution. The uniformly dispersed nanofiber mixture is poured into a multi-channel mold and freeze-dried to ob...

Embodiment 2

[0043] (1) 10g of gelatin is dissolved in 10ml of hexafluoroisopropanol, and it is continuously stirred until completely dissolved to obtain a gelatin solution with a concentration of 12% (mass volume ratio); 6g of PCL is dissolved in hexafluoroisopropanol, and Constantly stir until completely dissolving, obtain the PCL solution liquid that concentration is 8% (mass volume ratio); 10ml above-mentioned gelatin solution is mixed with 5ml above-mentioned PCL solution respectively, stir, obtain the spinning solution of gelatin / PCL; 4mg graphite Graphene is added to the above-mentioned spinning solution for ultrasonic dispersion to obtain a spinning solution of graphene / gelatin / PCL, spinning conditions: voltage 10 kV, receiving distance 10cm, spinning rate 1.2ml / h, electrospinning to obtain nanofiber membranes , stored in a vacuum oven for later use.

[0044] (2) Shred the nanofiber membrane obtained in step (1), weigh 0.5g of the fragments and add them to a beaker filled with 10ml...

Embodiment 3

[0047] (1) Place the silk at 95°C in a solution containing 5g / L Na 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, and dissolve it at 50°C±2°C for 70 minutes. Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

[0048] (2) Weigh 0.8g of silk fibroin obtained in step (1), dissolve 0.2g of PLCL in 10ml of hexafluoroisopropanol, stir until completely dissolved, and obtain a spinning solution with a concentration of 10% (w / v), Add 2mg of graphene oxide into the spinning solution and ultrasonically disperse to prepare the spinning solution of graphene oxide / silk fibroin / PLCL. Electrospin the spinning liquid, spinning conditions: voltage 14 kV, receiving distance 10cm, spinning rate 1.0ml / h, receive a certain thickness of na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com