Production process and production equipment of refrigerator door frame handle

A production process and handle technology, which is applied in the field of mechanical processing, can solve problems such as poor color and uneven surface smoothness, and achieve the effects of ensuring sandblasting processing efficiency, easy operation, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

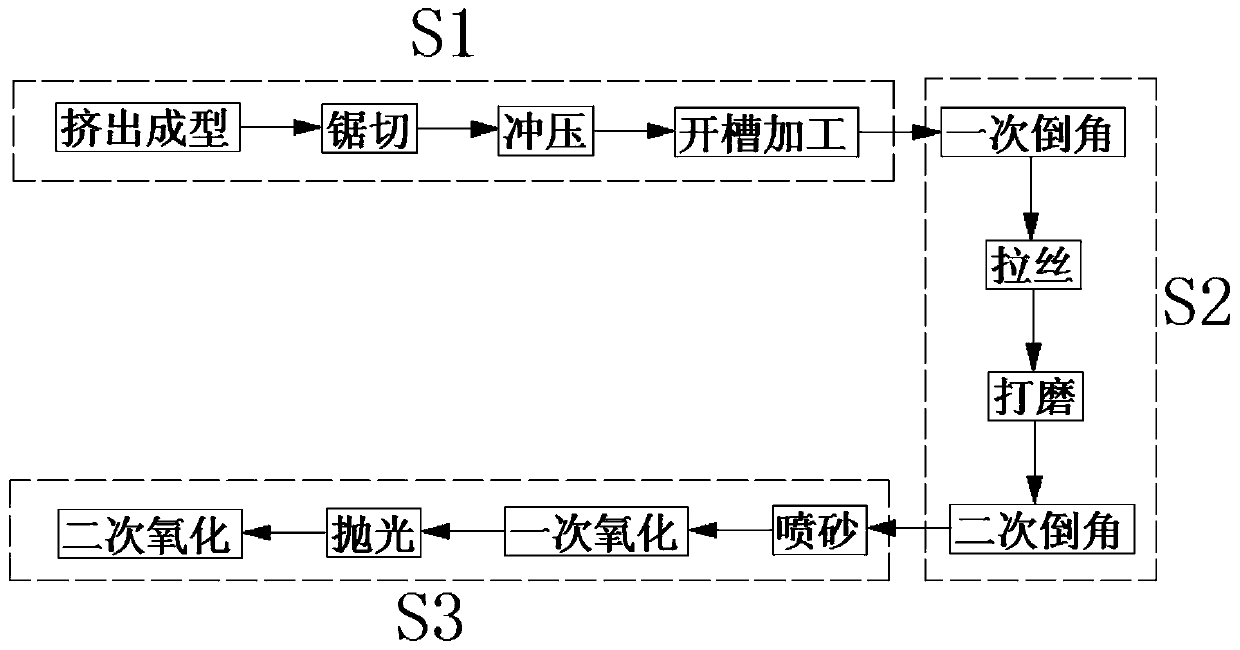

[0036] Such as figure 2 As shown, the aluminum alloy handle of the refrigerator door is prepared by the process of the present invention, and the aluminum alloy model is 6063.

[0037] S1: Preparation of the refrigerator door frame handle blank. According to the product size requirements of the handle, the handle rough blank is produced by extrusion molding process. The handle rough blank is sequentially processed by sawing, stamping and CNC machine tool to obtain the refrigerator door frame handle blank;

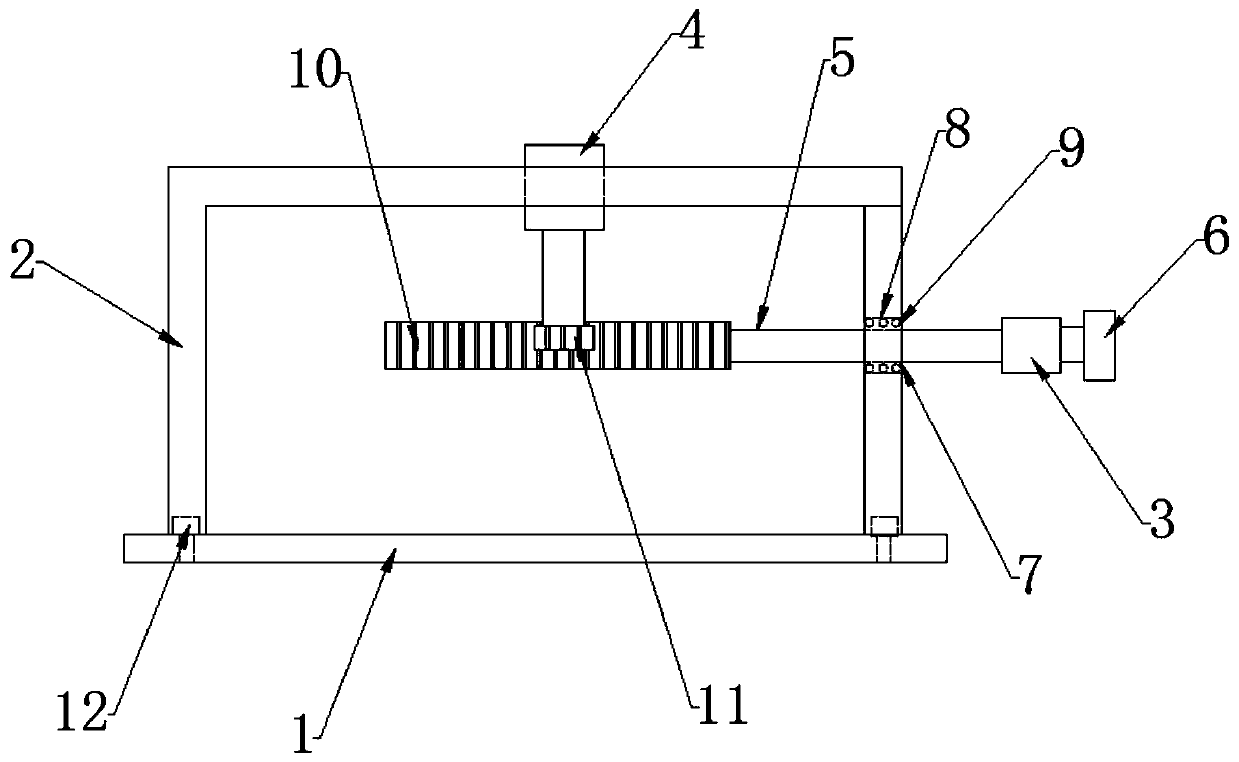

[0038] S2: Refining the surface of the refrigerator door frame handle blank. The surface of the refrigerator door frame handle blank produced in step S1 is subjected to a chamfering treatment, wire drawing treatment, polishing treatment and a second chamfering treatment in sequence to obtain a refrigerator door frame handle initial product, wherein the wire drawing treatment The used grinding wheel is connected to the grinding wheel driving stepping motor, and the grinding...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that in the step S2 wire drawing process, the peripheral surface of the grinding wheel is alternately provided with end-to-end arc-shaped areas of 200 mesh, 250 mesh and 300 mesh, and the rotation speed of the grinding wheel is 2400r / min The model of sandpaper used in the step S2 grinding process is 400 orders; the step S3 sand blasting process uses steel grit as the spray material, and the model of the steel grit is 150 orders, and the pressure of the sand blasting process is 3.5kg / cm 2 The primary oxidation treatment in step S3 is to put the refrigerator door frame handle into the anodizing tank, the anode voltage is 14V, the oxidation time is 40min, the solution concentration in the anodizing tank is a sulfuric acid solution of 220g / L, and the oxidation temperature is 20°C The step S3 secondary oxidation treatment is to put the refrigerator door frame handle into the anodizing tank, the anode voltage is 11V, th...

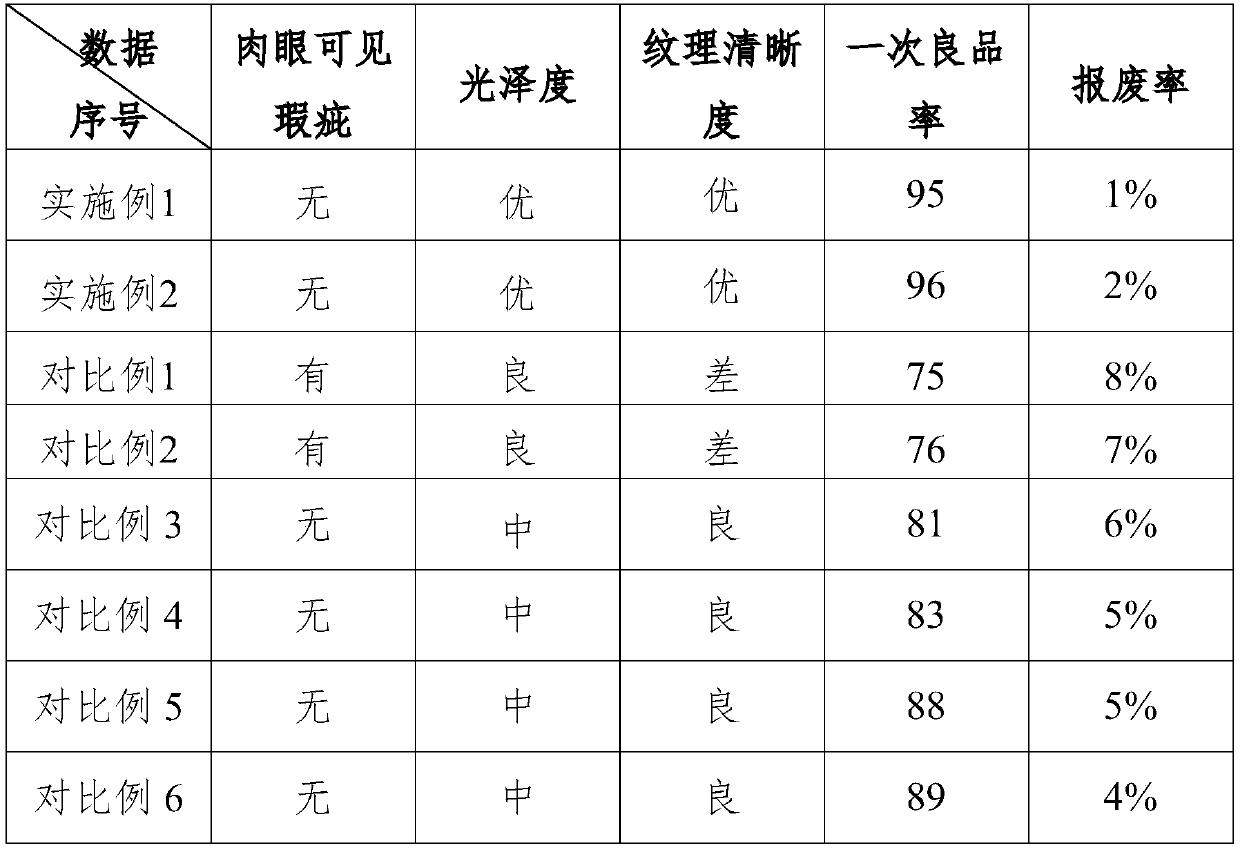

Embodiment 1~2 and comparative example 1~6

[0055] Embodiment 1~2 and comparative example 1~6 experimental data

[0056]

[0057] Experimental results show that: the outer surface of the aluminum alloy handle of the refrigerator door frame prepared by the process of the present invention in Examples 1-2 has no visible flaws, excellent gloss, excellent texture clarity, a first-time good product rate of more than 95%, and a product scrap rate of 2% or less; the aluminum alloy handles of the refrigerator door frames produced in Comparative Examples 1-2 did not adopt the drawing process, and the outer surface of the aluminum alloy handles of the refrigerator door frames produced had defects visible to the naked eye, and the gloss and texture clarity were better than those in Examples 1-2 Poor, the first-time product yield is about 75%, and the product scrap rate is over 7%; the outer surface of the aluminum alloy handle of the refrigerator door frame produced in Comparative Examples 3 to 6 has no visible flaws with the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com