Solution method for preparing high-efficiency CIS and CIGS thin-film solar cell

A technology of solar cells and copper indium gallium selenide, which is applied in the field of solar energy, can solve the problems affecting the performance of copper indium gallium selenide and the unstable existence of monovalent copper ions, etc., achieves cheap and easy to obtain, avoids redox reactions, and prevents metal ions The effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

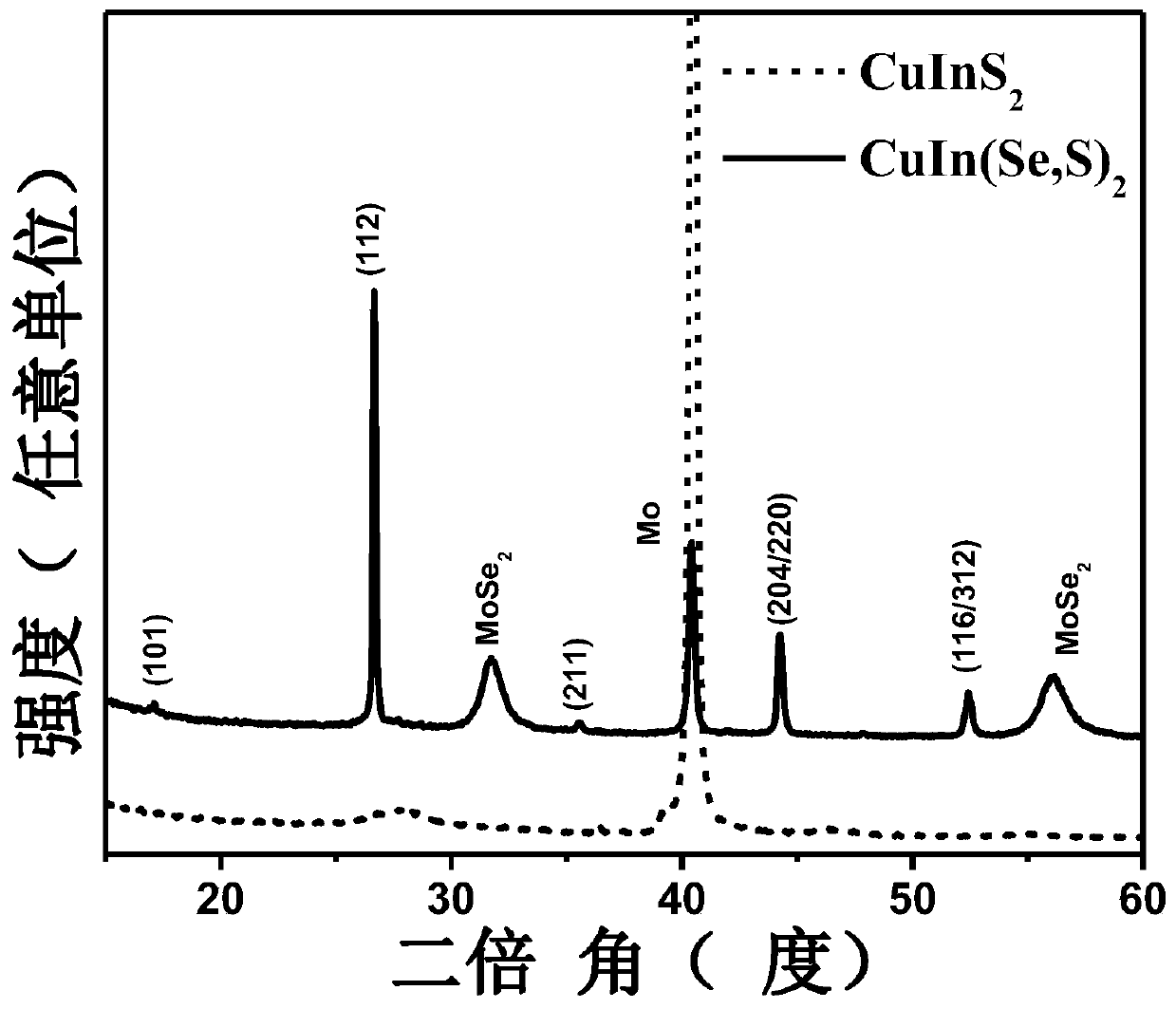

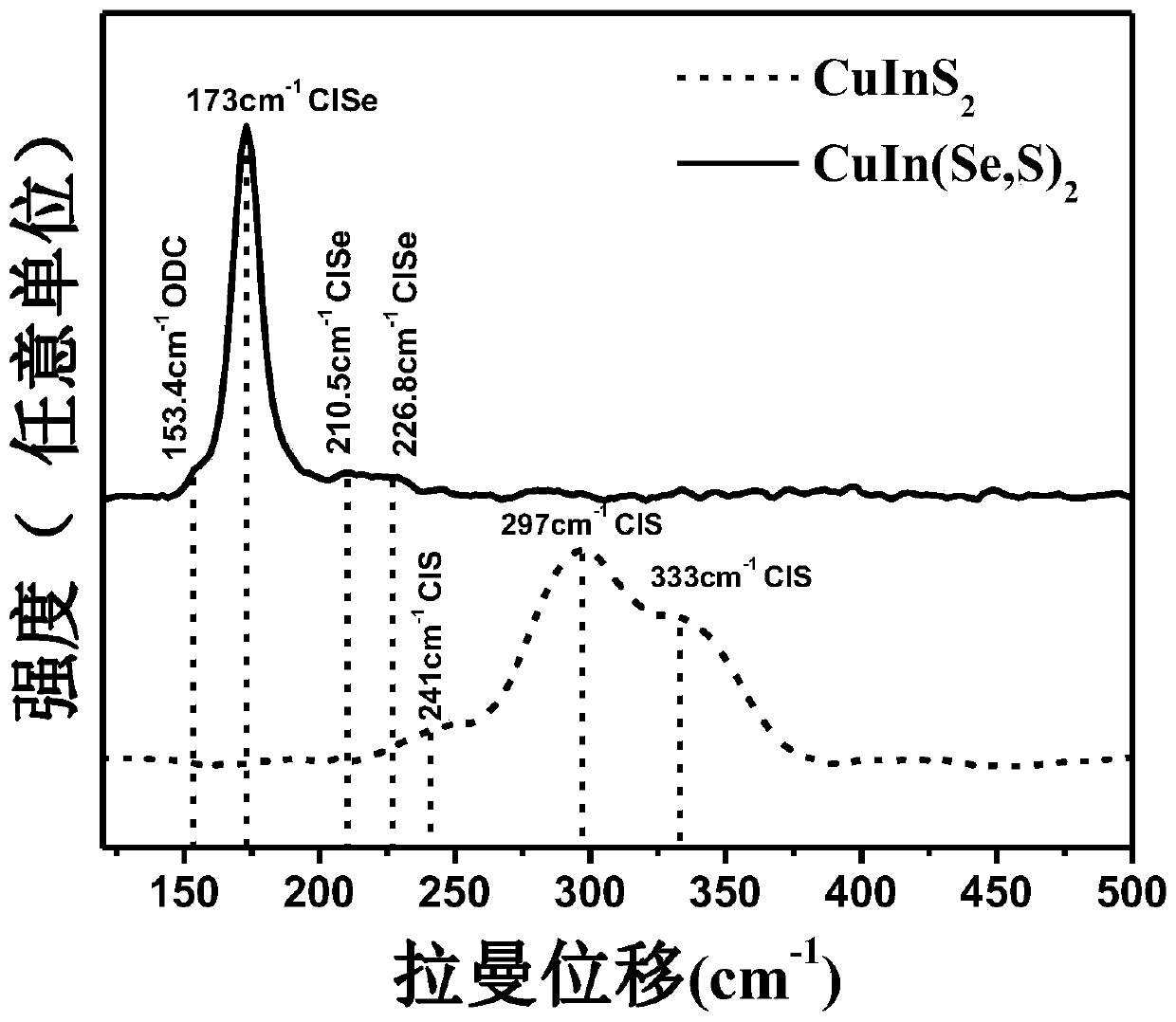

[0072] Example 1: A precursor solution was prepared using the synthesized thiourea complex of copper and indium as a raw material and water as a solvent, and a CIS solar cell was prepared with the solution.

[0073] Synthesis of copper thiourea complex (CuTU 3 Cl): Take 150mL of ultrapure water and add it to a 500mL beaker, heat it to 60°C, then add 30g of thiourea into it, and stir until completely dissolved. Weigh 6g of copper powder and add it to the solution, put it in an oil bath at 110°C, add 95mL of concentrated hydrochloric acid after the temperature rises to 110°C, observe that the red copper powder disappears, and a white solid appears, and the white solid continues to increase and becomes flocculent. Water makes the solution clear and transparent. Then filter while it is hot, and the filtrate is left to cool. After a period of time, a large amount of white elongated columnar solids appear at the bottom of the beaker. The obtained solid was filtered, washed with ac...

Embodiment 2

[0080] Example 2: Prepare a precursor solution by using the synthesized copper and indium thiourea complex as raw material and water as solvent, and prepare a CIS solar cell with the solution.

[0081] Preparation of precursor solution: weigh 0.9896g CuTU respectively 3 Cl and 1.8024g InTU 3 Cl 3 Add it to a 20mL sample bottle, then add 10mL of ultrapure water, stir magnetically at 85°C to obtain a colorless and transparent mixed solution, and filter the mixed solution with a 0.45μm PES filter membrane.

[0082] Preparation of copper indium sulfide (CIS) precursor film: fix the cleaned glass (molybdenum glass) coated with metal molybdenum on the suction cup of the homogenizer, measure the precursor solution with a pipette gun, and drop it on the molybdenum glass , 2000 rpm spin coating 30s. Immediately afterwards, the sample was heated (annealed) for 1 min on a hot stage preheated to 270°C. After the sample is cooled, repeat the above spin-coating-heating process 20 times....

Embodiment 3

[0085] Example 3: A precursor solution was prepared using the synthesized thiourea complex of copper, indium and gallium as a raw material and water as a solvent, and a CIGS solar cell was prepared with the solution.

[0086] Prepare CIGS precursor solution: weigh 0.35g CuTU respectively 3 Cl, 0.45g InTU 3 Cl 3 and 0.16g GaTU 6 Cl 3 Add it to a 20mL sample bottle, then add 10mL of ultrapure water, stir magnetically at 85°C to obtain a colorless and transparent mixed solution, and filter the mixed solution with a 0.45μm PES filter membrane.

[0087] Preparation of copper indium gallium sulfide (CIGS) precursor film: fix the cleaned glass (molybdenum glass) coated with metal molybdenum on the suction cup of the homogenizer, measure the precursor solution with a pipette gun, and drop it on the molybdenum glass On, spin coating at 2000 rpm for 30s. Immediately afterwards, the sample was heated (annealed) for 1 min on a hot stage preheated to 270°C. After the sample is cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com