NiFeMo ternary electrolytic water electrode and preparation method thereof

A technology for electrolyzing water and electrodes, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of unsatisfactory hydrogen evolution (HER) performance, low oxygen evolution performance, etc. The effect of low thermal reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

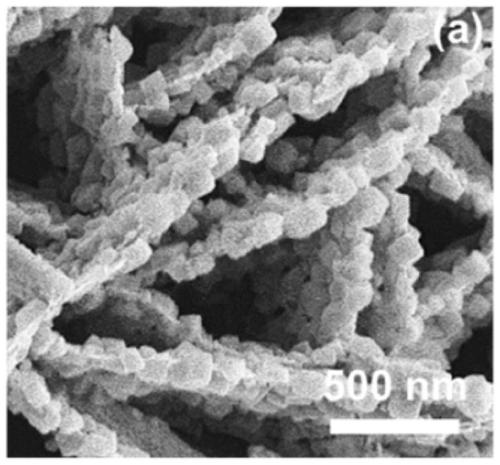

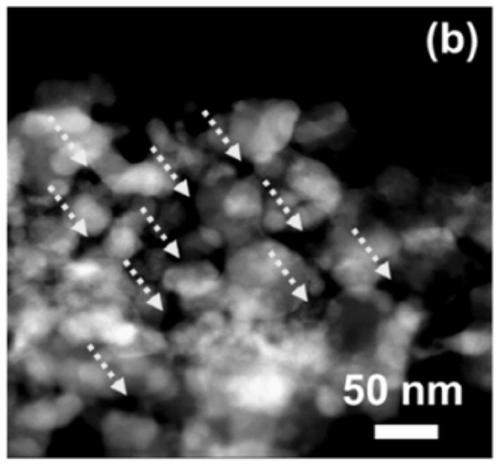

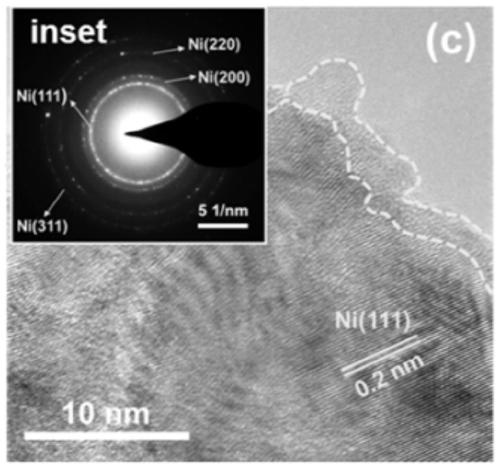

Image

Examples

Embodiment 1

[0048] Weigh 0.24g of urea, 0.05g of ammonium fluoride, 0.4mmol of ferric nitrate nonahydrate, 8mmol of nickel nitrate hexahydrate and dissolve them in 40ml of deionized water. After stirring and dissolving, transfer them to a 50ml reaction kettle and add a piece of Nickel foam is heated in an oven at 100°C for 2 hours. After the end, take out the nickel foam and wash it to obtain a nickel foam material covered with a yellow-green material on the surface, put it into 40ml of ammonium heptamolybdate aqueous solution with a substance concentration of 20mmol / L, and transfer it to a 50ml reaction kettle for 10h at 120°C. After cleaning, the foam nickel material covered with brick red material is obtained. After drying, put it into the tube furnace quartz furnace tube, maintain the carbon monoxide atmosphere, raise the temperature to 350 °C at a rate of 5 °C / min and keep it for 2 hours. The material changes from brick red to 350 °C. Turned into black, the obtained NiFeMo ternary el...

Embodiment 2

[0050] Weigh 0.6g of urea, 0.2g of ammonium fluoride, 8mmol of ferric nitrate nonahydrate, and 8mmol of nickel nitrate hexahydrate in 40ml of deionized water. After stirring and dissolving, transfer it to a 50ml reaction kettle and add a piece of 0.1g of it washed with 3mol hydrochloric acid. Nickel foam, oven 100 ℃ water heating 20h. After the completion, take out the nickel foam and wash it to obtain a nickel foam material covered with a yellow-green material on the surface, put it into 40ml of ammonium heptamolybdate aqueous solution with a substance concentration of 40mmol / L, and transfer it to a 50ml reactor for 20h at 150°C. Wash to obtain the foamed nickel material of brick red material on the surface after finishing, put into tube furnace quartz furnace tube after drying, maintain 5% (5% V H2 / 95%V Ar ) mixed atmosphere of hydrogen and argon, the temperature was raised to 300°C at a rate of 5°C / min and kept for 10h, the material changed from brick red to black, and th...

Embodiment 3

[0052] Weigh 0.6g of urea, 0.2g of ammonium fluoride, 0.4mmol of ferric nitrate nonahydrate, 5mmol of nickel nitrate hexahydrate in 40ml of deionized water, stir and dissolve, transfer to a 50ml reaction kettle and add a piece of 0.6g to wash with 3mol hydrochloric acid For nickel foam, heat in water at 120°C for 12 hours in an oven. After the end, take out the nickel foam and wash it to obtain a nickel foam material covered with a yellow-green material on the surface, put it into 40ml of ammonium heptamolybdate aqueous solution with a substance concentration of 10mmol / L, and transfer it to a 50ml reactor for 120°C hydrothermal heating for 10h. Wash to obtain the foamed nickel material of brick red material on the surface after finishing, put into tube furnace quartz furnace tube after drying, maintain 5% (5% V H2 / 95%V Ar ) in a mixed atmosphere of hydrogen and argon, the temperature was raised to 400°C at a rate of 5°C / min and kept for 2 hours, the material turned from bric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com