Low-grade heat energy driven electrode liquid independent hydrogen production method

A low-grade, electrode liquid technology, applied in the electrolysis process, electrolysis components, regenerative fuel cells, etc., can solve the problems of high electrode potential, large energy conversion loss, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

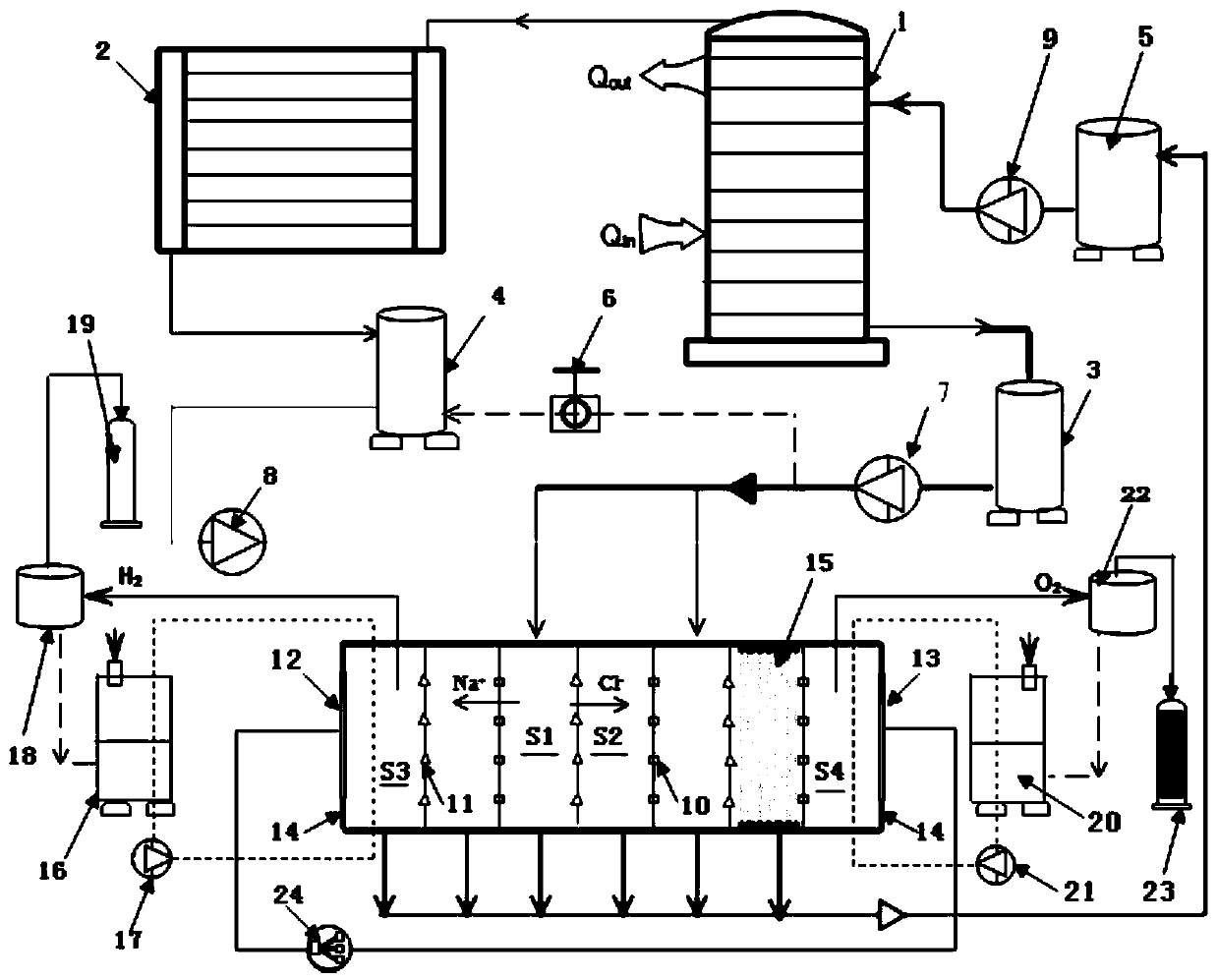

[0028] Example 1: figure 1 It shows a working flow of a hydrogen production method driven by low-grade thermal energy driven by the reverse electrodialysis principle (without plug-in).

[0029] In the first step, the low-grade thermal energy stream (such as low-temperature heat transfer oil with a temperature of 120-130°C) enters the generator 1 from the inlet of the driving heat source at the bottom left of the generator 1, and the working solution (such as chlorinated Sodium aqueous solution), after releasing heat and cooling down to about 60°C, leave the generator 1 from the outlet of the driving heat source on the upper left of the generator 1. After the waste liquid in the generator 1 is heated by the low-grade thermal energy stream, part of the solvent and a very small amount of solute will evaporate, and escape from the top of the generator in gaseous form and enter the condenser 2. After condensation, phase change, and cooling down to about 50°C in the condenser 2, it...

Embodiment 2

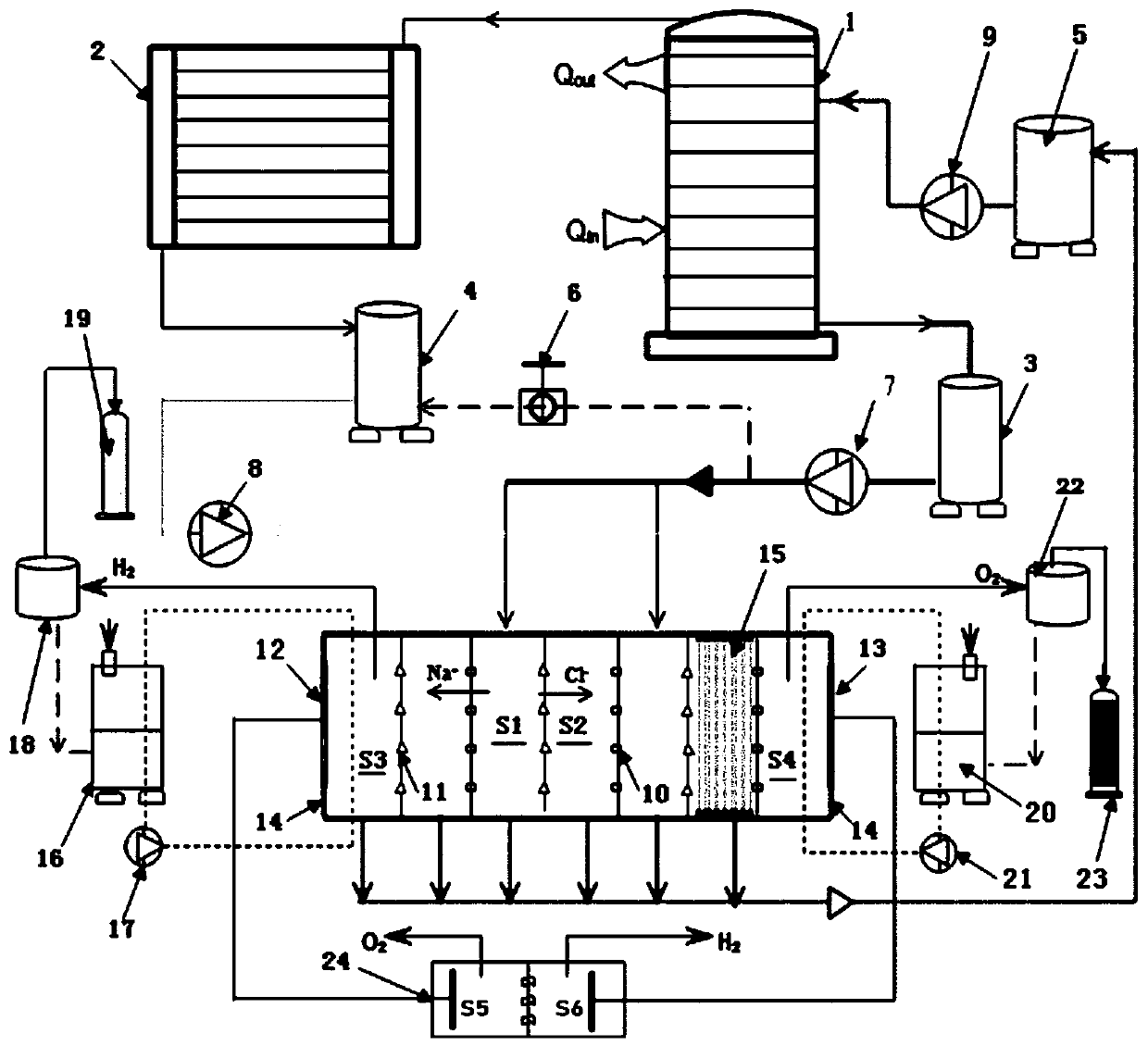

[0039] On the basis of Example 1, if the number of anion and cation exchange membranes (which can significantly improve the output voltage of the reverse electrodialysis stack) is increased to more than 30 pairs, and the variable load 24 is selected as an external electrolyzer, then the reverse electrodialysis Hydrogen production by dialysis-water electrolysis method can produce hydrogen and oxygen at the same time, so that more hydrogen and oxygen can be produced on the original basis. figure 2 shown.

[0040] figure 2 It shows the work flow of a hydrogen production method based on the principle of reverse electrodialysis and driven by low-grade thermal energy for each independent type (external electrolyzer) of the electrode solution. The principle is basically similar to that of Embodiment 1, and the same parts will not be repeated. In addition to increasing the number of ion exchange membranes, the key difference is that the specific embodiment 2 uses an external elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com