Anti-staining silk and wool washing liquid detergent and preparation method thereof

An anti-staining and detergent technology, applied in the directions of detergent compounding agents, detergent compositions, chemical instruments and methods, etc. Adapt to requirements and other issues, achieve low damage, improve antibacterial and antiseptic properties, and avoid clothing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

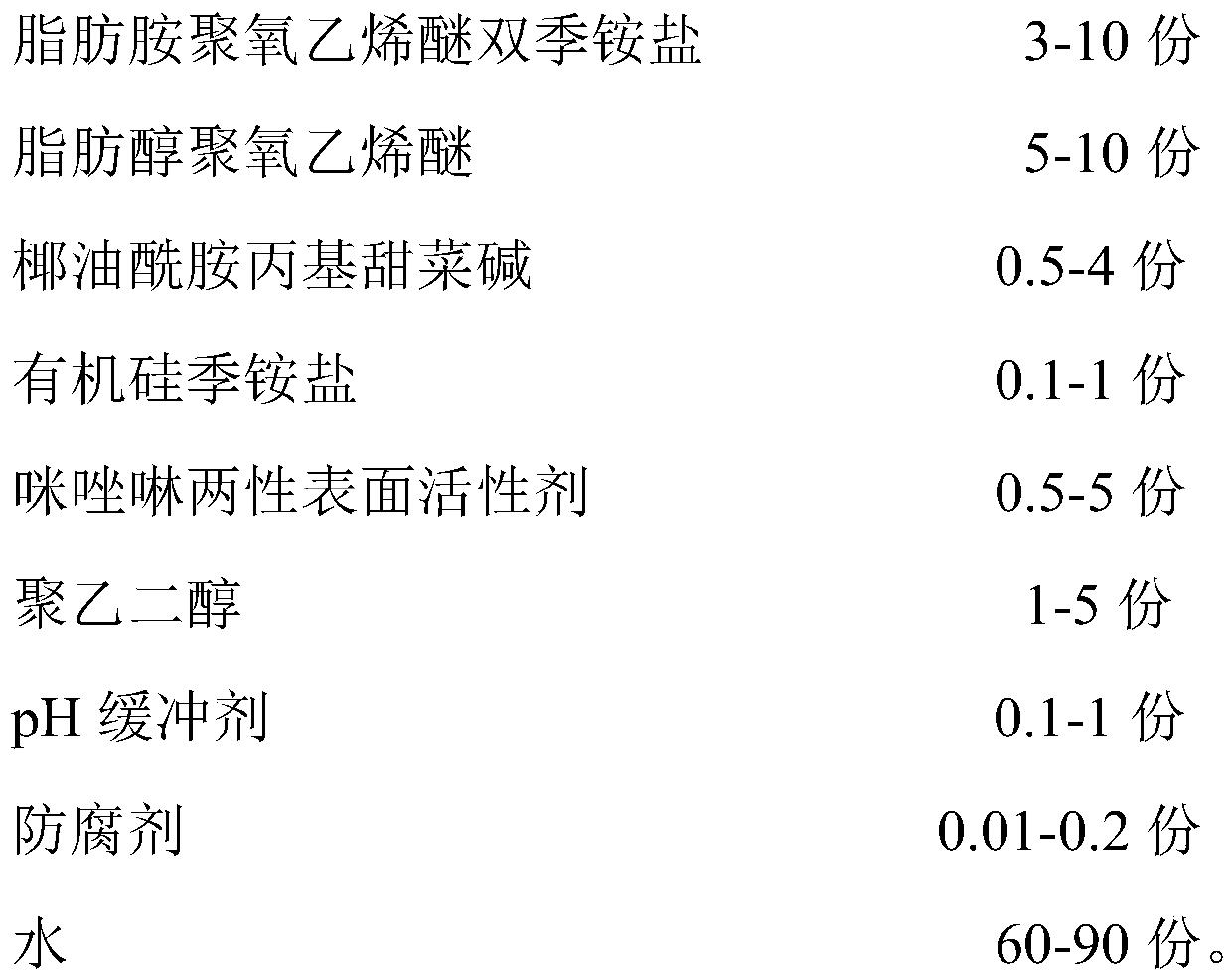

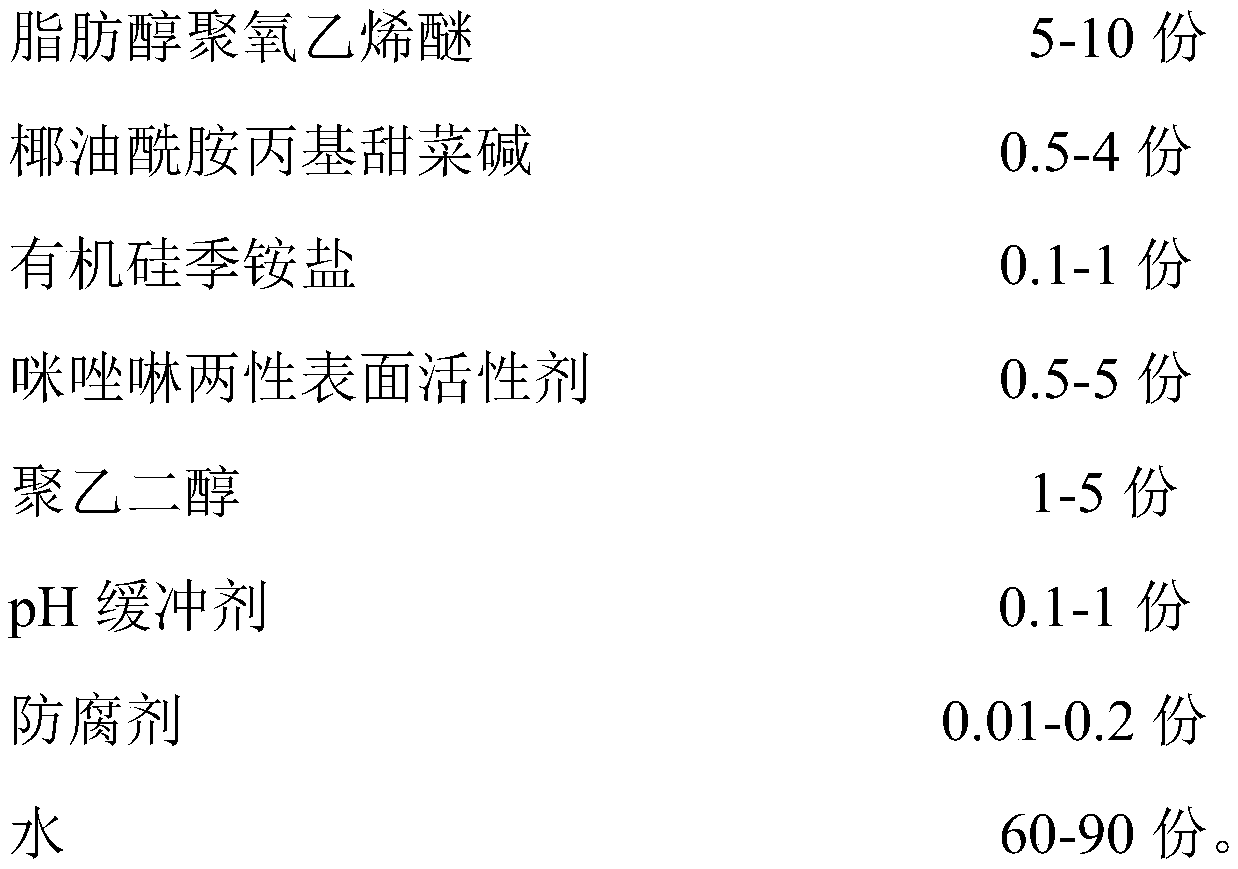

[0036] An anti-staining silk wool cleansing agent, comprising the following components by weight:

[0037]

[0038] Described water adopts deionized water.

[0039] The fatty amine polyoxyethylene ether diquaternary ammonium salt is dichloride dihexadecyl polyoxyethylene ether biphenyl benzyl ammonium, dichloride dioctadecyl polyoxyethylene ether biphenyl benzyl ammonium and dichloride dioctadecyl polyoxyethylene ether biphenyl benzyl ammonium and dichloride Ditetradecyl polyoxyethylene ether biphenyl benzyl ammonium chloride is mixed at a weight ratio of 1:5:1.

[0040] The fatty alcohol polyoxyethylene ether is formed by mixing AEO-9, AEO-7 and AEO-3 in a weight ratio of 5:2:1.5.

[0041] The cocamidopropyl betaine is CAB-35.

[0042] The organic silicon quaternary ammonium salt is 3-(trimethoxysilyl) propyl octadecyl dimethyl ammonium chloride and dodecyl dimethyl benzyl ammonium chloride in a weight ratio of 1:2. become.

[0043] The imidazoline amphoteric surfactan...

Embodiment 2

[0052] An anti-staining silk wool cleansing agent, comprising the following components by weight:

[0053]

[0054]

[0055] Described water adopts demineralized water.

[0056] The fatty amine polyoxyethylene ether diquaternary ammonium salt is dichloride dihexadecyl polyoxyethylene ether biphenyl benzyl ammonium, dichloride dioctadecyl polyoxyethylene ether biphenyl benzyl ammonium and dichloride dioctadecyl polyoxyethylene ether biphenyl benzyl ammonium and dichloride Ditetradecyl polyoxyethylene ether biphenyl benzyl ammonium chloride is mixed at a weight ratio of 1:3:1.

[0057] The fatty alcohol polyoxyethylene ether is formed by mixing AEO-9, AEO-7 and AEO-3 in a weight ratio of 3:1:1.

[0058] The cocamidopropyl betaine is CAB-30.

[0059] The organic silicon quaternary ammonium salt is 3-(trimethoxysilyl) propyl octadecyl dimethyl ammonium chloride and dodecyl dimethyl benzyl ammonium chloride in a weight ratio of 1:2. become.

[0060] The imidazoline amphot...

Embodiment 3

[0069] An anti-staining silk wool cleansing agent, comprising the following components by weight:

[0070]

[0071] Described water adopts deionized water.

[0072] The fatty amine polyoxyethylene ether diquaternary ammonium salt is dichloride dihexadecyl polyoxyethylene ether biphenyl benzyl ammonium, dichloride dioctadecyl polyoxyethylene ether biphenyl benzyl ammonium and dichloride dioctadecyl polyoxyethylene ether biphenyl benzyl ammonium and dichloride Ditetradecyl polyoxyethylene ether biphenyl benzyl ammonium chloride is mixed at a weight ratio of 1:6:1.

[0073] The fatty alcohol polyoxyethylene ether is formed by mixing AEO-9, AEO-7 and AEO-3 in a weight ratio of 8:3:2.

[0074] The cocamidopropyl betaine is CAB-35.

[0075] The organic silicon quaternary ammonium salt is 3-(trimethoxysilyl) propyl octadecyl dimethyl ammonium chloride and dodecyl dimethyl benzyl ammonium chloride in a weight ratio of 1:2. become.

[0076] The imidazoline amphoteric surfactant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com