Particle electrode and preparation method thereof and three-dimensional electrolytic reactor and application of three-dimensional electrolytic reactor

A granular electrode and three-dimensional electrolysis technology, which is applied in chemical instruments and methods, light water/sewage treatment, water pollutants, etc., can solve the problems of unsuitable strong acid and strong alkaline wastewater, less research on three-dimensional electrolysis systems, and the loss of active components of catalysts and other issues, to achieve the effects of recycling, improving photocatalytic efficiency, and eliminating short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

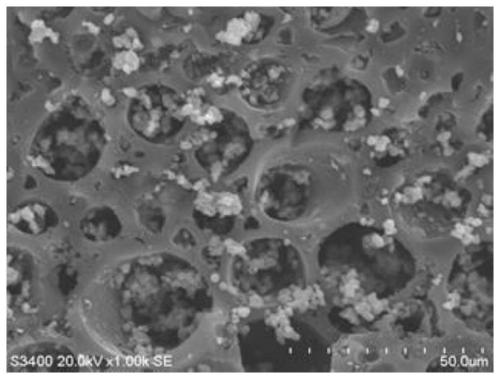

[0033] g-C 3 N 4 -TiO 2 Preparation of / AC granular electrode filler:

[0034] S1: Pretreatment of activated carbon: screen activated carbon of 7 to 14 mesh, soak it with 10% hydrochloric acid solution and 5% NaOH solution at room temperature, and clean it with ultrasonic vibration for 30 minutes, then wash it with distilled water several times, and then wash the treated Put the activated carbon in an oven and dry it at 100°C for 12 hours, and cool it for later use;

[0035] S2: g-C 3 N 4 Preparation: Weigh 10g of melamine in a crucible, cover the crucible and put it into a muffle furnace for calcination. The heating rate is 3-4°C / min, and the temperature is 500°C. After burning for 2 hours, cool naturally and grind it into powder particles. spare;

[0036] S3: Fully mix 40mL of absolute ethanol, 10mL of acetic acid and 20mL of tetrabutyl titanate. After stirring, a clear solution is obtained. Weigh 5g of g-C 3 N 4 Put the powder particles into the solution and stir to o...

Embodiment 2

[0041] g-C 3 N 4 -TiO 2 Preparation of / AC granular electrode filler:

[0042] S1: Pretreatment of activated carbon: screen activated carbon of 7 to 14 mesh, soak it with 6% hydrochloric acid solution and 10% NaOH solution at room temperature, and clean it with ultrasonic vibration for 30 minutes, then wash it with distilled water several times, and then wash the treated Put the activated carbon in an oven and dry it at 120°C for 12 hours, and cool it for later use;

[0043] S2: g-C 3 N 4 Preparation: Weigh 10g of melamine in a crucible, cover the crucible and put it into a muffle furnace for calcination. The heating rate is 3-4°C / min, and the temperature is 550°C. After burning for 3 hours, cool naturally and grind it into powder particles. spare.

[0044] S3: Fully mix 40mL of absolute ethanol, 10mL of acetic acid and 20mL of tetrabutyl titanate. After stirring, a clear solution is obtained. Weigh 5g of g-C 3 N 4 Put the powder particles into the solution and stir to...

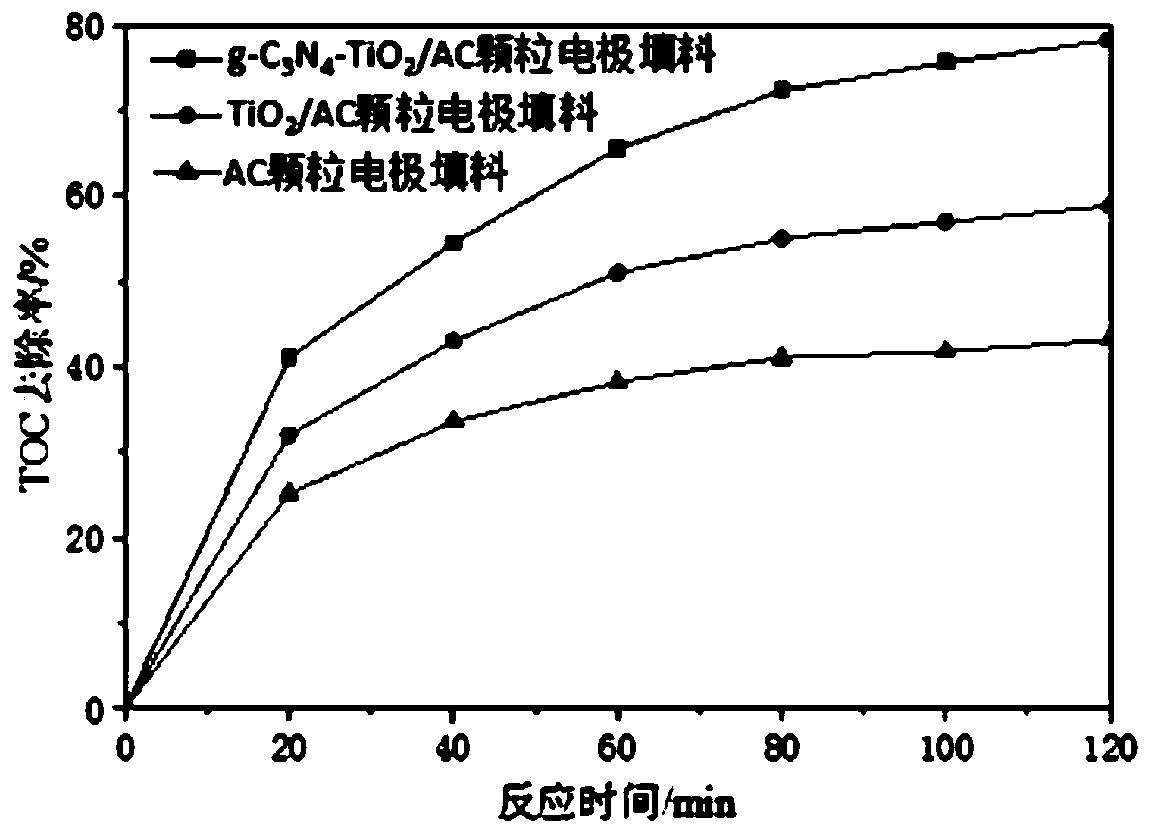

experiment example 1

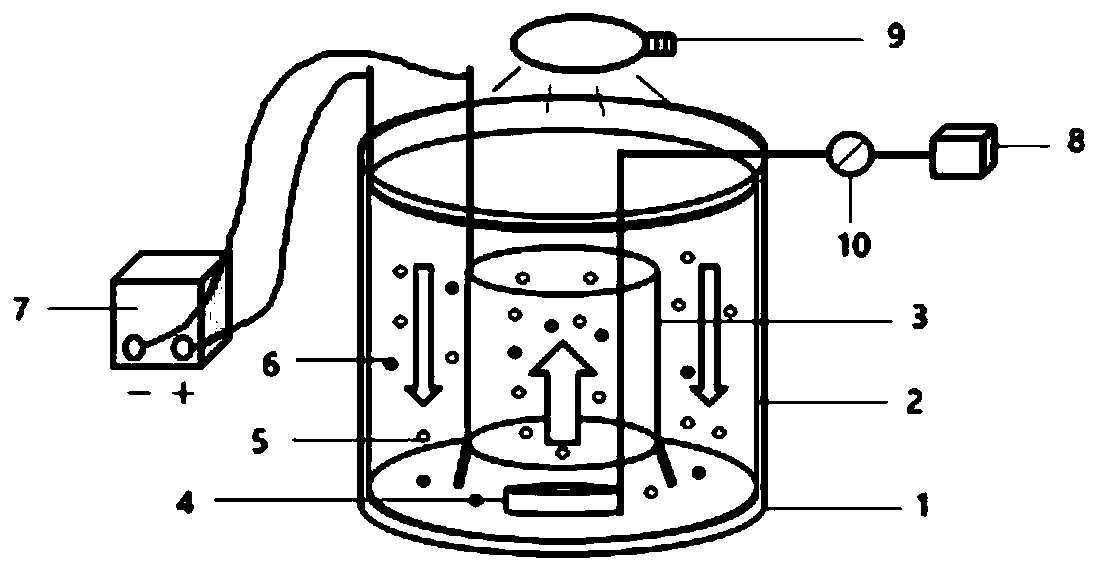

[0056] like figure 2 Shown: the three-dimensional electrolysis reactor of the present invention includes a fluidized bed reactor 1 and a xenon lamp 9 that provides illumination for the system in the fluidized bed reactor 1; the fluidized bed reactor 1 is provided with a cathode stainless steel cylinder 3 and an anode titanium cylinder 2. During the reaction, the fluidized bed reactor 1 is also filled with g-C 3 N 4 -TiO 2 / AC particle electrode 6; the anode titanium cylinder 2 is sleeved outside the cathode stainless steel cylinder 3, the distance between the two electrodes is 4cm, and metal strips are welded on the two electrode tubes to connect the DC steady-current power supply 7, and the cathode stainless steel cylinder 3 is also the guide cylinder Function: the cathode stainless steel cylinder 3 is set in the fluidized bed reactor 1 through an iron frame, so that there is a gap between the bottom of the fluidized bed reactor 1 and the bottom of the cathode stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com