Perylene imide derivative self-assembly film and preparation method and application thereof

A technology of perylene imide and derivatives, which is applied in the field of self-assembled films of perylene imide derivatives and its preparation, which can solve the problem that perylene imide derivatives are difficult to form films, easy to fall off, and limit the application of electrochromic materials, etc. problem, achieving reversible color change, short response time, and high contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the synthesis of PPDI

[0041] (1) Synthesis of N,N'-bis(2-bisimidazolyl phosphate)-3,4,9,10-perylenetetracarboxylic acid diimide

[0042]Add perylene-3,4,9,10-tetraanhydride dianhydride (157mg, 0.40mmol), 2-aminoethylphosphonic acid ((100mg, 0.80mmol) and imidazole ( (0.5g, 7.35mmol). After it was mixed uniformly, the temperature was raised to 135°C. At this moment, imidazole melted into a liquid state, reacted for 15min, and reached the end of the reaction. Turn off the heating device, and wait for the reaction to be cooled to room temperature to obtain solid crude product. Crude product Wash and filter with (ethanol: 2mol / L HCl = 1:1), (ethanol: water = 1:1) and ethanol solution respectively, filter off the filtrate, and dry under vacuum to obtain N,N'-bis(2- 200mg of bisimidazolylethyl phosphate)-3,4,9,10-perylenetetracarboxylic acid diimide, the yield was 74.3%, and the product was a dark red solid.

[0043] (2) Synthesis of N,N'-bis(2-disodium ethy...

Embodiment 2

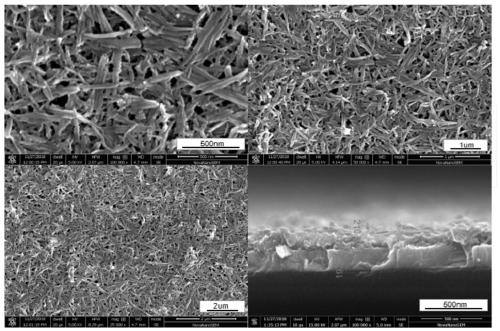

[0049] Embodiment 2: Preparation of PPDI self-assembled film

[0050] Add deionized water (200mL), hydrogen peroxide (40mL) and ammonia water (20mL) into a pre-dried 250mL beaker, then place the pre-cleaned ITO glass in the above solution, heat the solution to 60°C and keep it for 1h After the heating is completed, rinse with deionized water for 3 times and dry in an oven at 60°C for 1 hour. At this time, a layer of -OH will be adsorbed on the surface of ITO. Then put the processed ITO into ZrOCl 2 (5mmol / L) aqueous solution, at room temperature for 12h, at this time -OH on the ITO will react with ZrOCl 2 Zr in 4+ Form a chemical bond, thereby adsorbing a layer of Zr 4+ . Then put ITO into PPDI (1mmol / L) aqueous solution, and let it stand at room temperature for 12h. At this time the Zr on the ITO 4+ It will form a chemical bond with -OH in PPDI, thereby adsorbing a layer of PPDI. Repeat the above steps 8 times to obtain the perylene imide derivative self-assembled film...

Embodiment 3

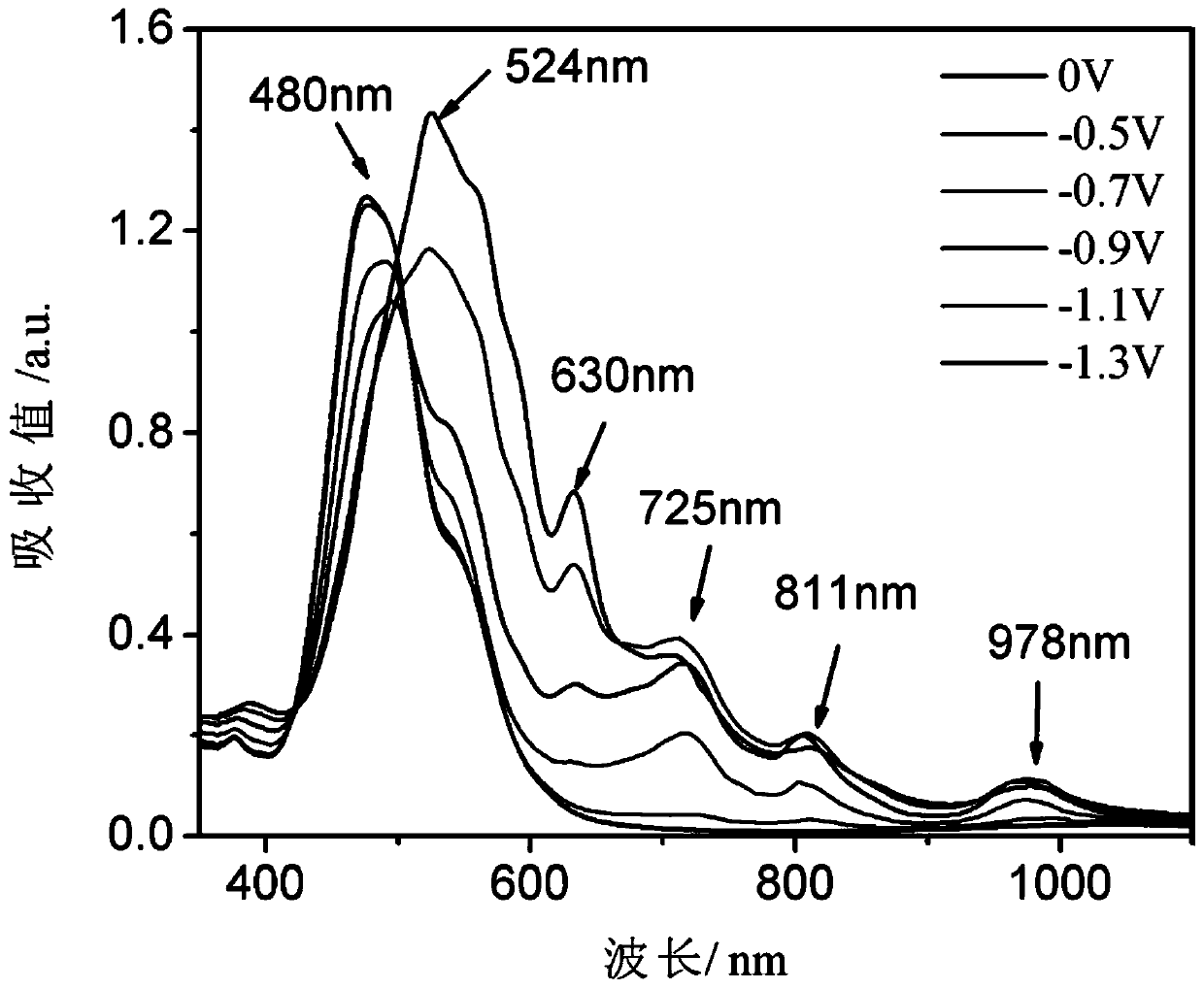

[0052] Example 3: Electrochromic properties of PPDI self-assembled films

[0053] The PPDI self-assembled film attached to the ITO glass prepared in Example 2 is put into a three-electrode electrolytic cell to dissolve 0.2mol / L 1-butyl-3 methyl-imidazole trifluoromethanesulfonate / carbonic acid Propylene ester solution is used as electrolytic solution, wherein the working electrode is ITO glass with perylene imide derivative self-assembled film, the counter electrode is platinum wire, and the reference electrode is silver-silver chloride electrode. Cyclic voltammetry was used for scanning, the scanning voltage range was 0-1.3V, the scanning speed was 100mV / s, and the scanning was performed for 10 cycles. It can be observed with the naked eye that the color of the film changes from red to purple as the negative voltage decreases, and when the negative voltage increases, the color turns red again, and so on. The relationship between the redox peaks on the cyclic voltammetry curv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com