Electrical connector and conductive terminal thereof

A technology of conductive terminals and electrical connectors, applied in the direction of connection, parts of connecting devices, circuit/collector parts, etc., can solve problems such as damage to electrical connectors, achieve high corrosion resistance, and reduce short-circuit fire. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

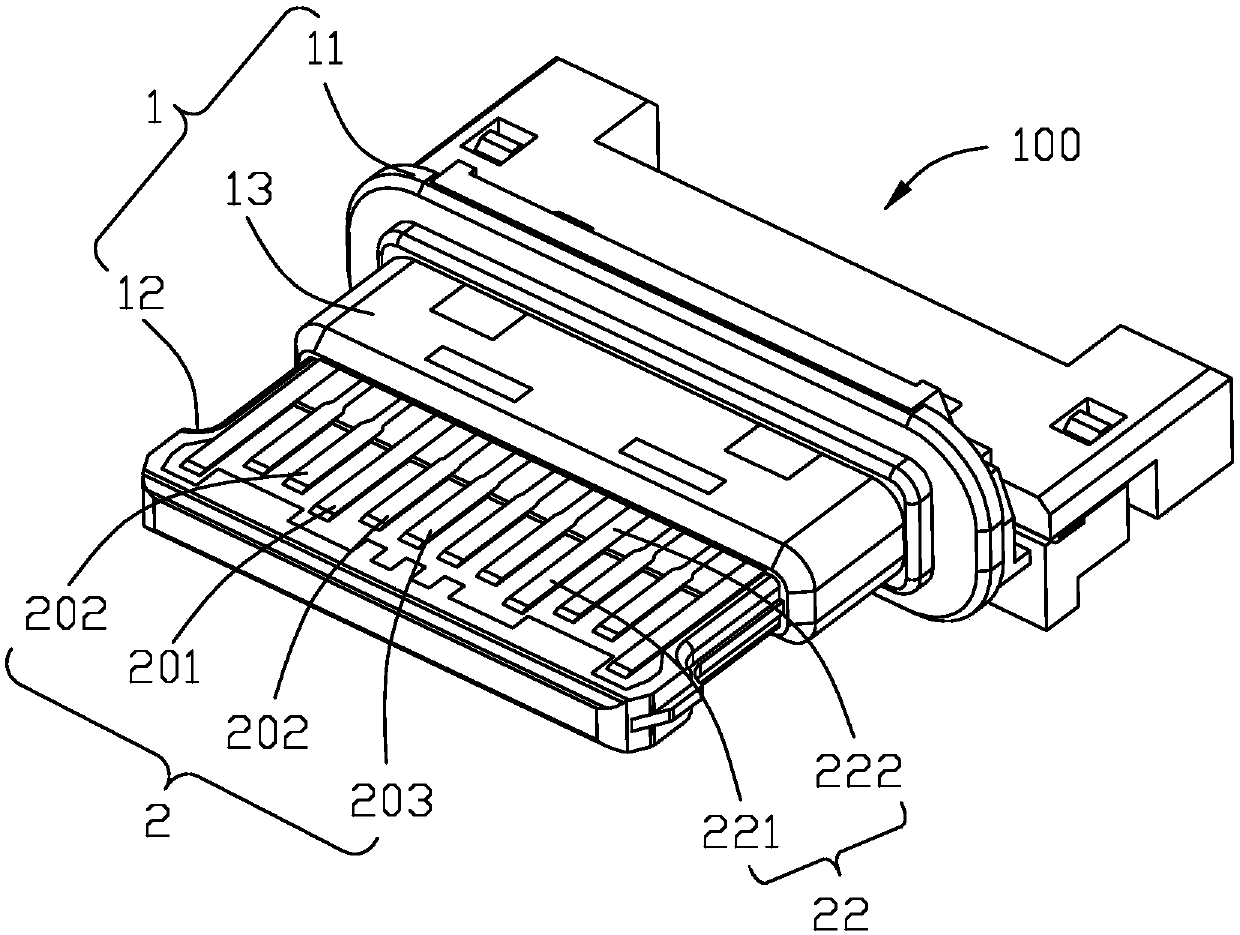

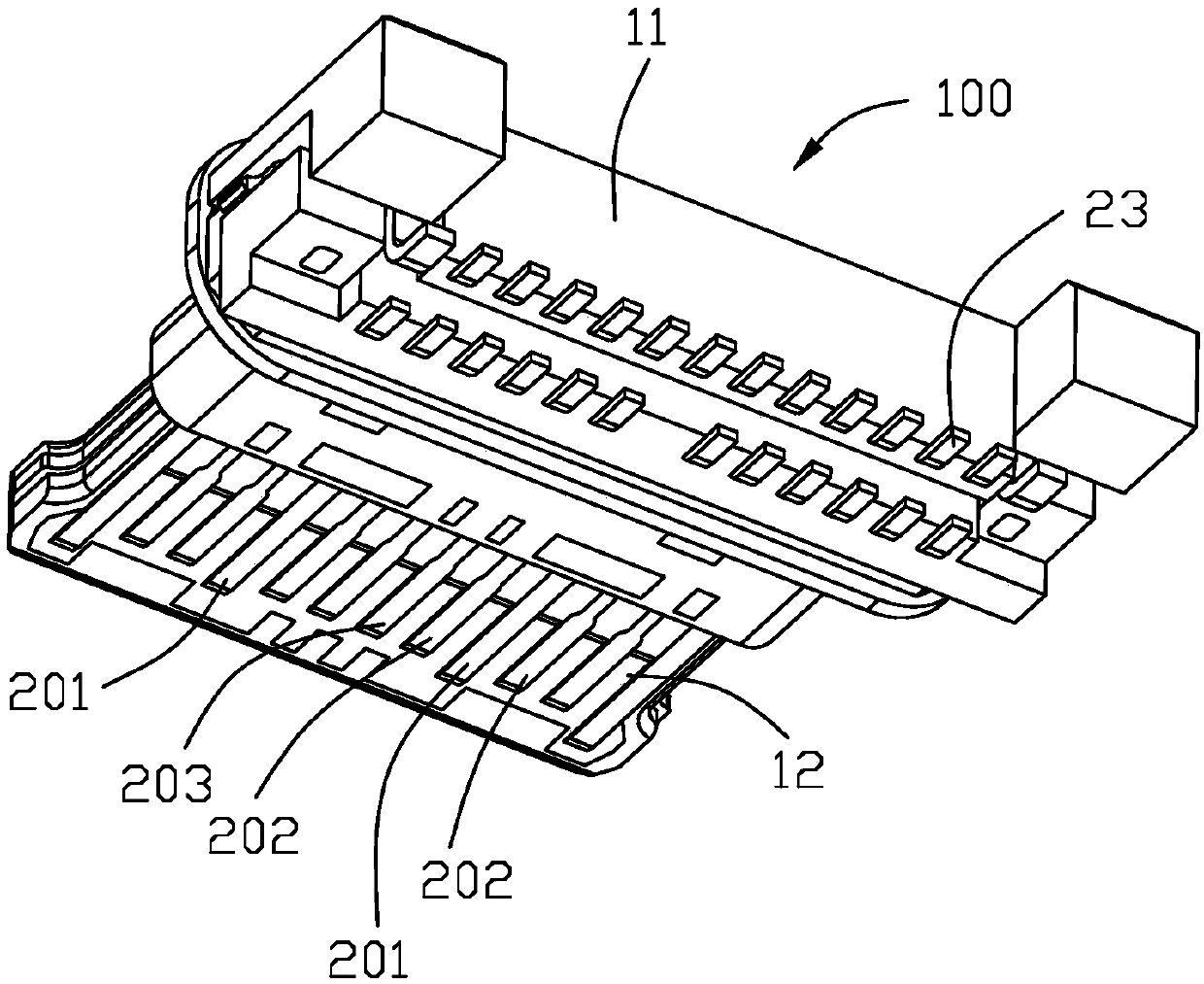

[0022] Please refer to Figure 1 to Figure 5 As shown, the electrical connector 100 of the present invention is a connector for being installed on a circuit board (not shown) and can be plugged in both front and back. The electrical connector 100 includes an insulating body 1 , and conductive terminals 2 arranged in two rows above and below the insulating body 1 .

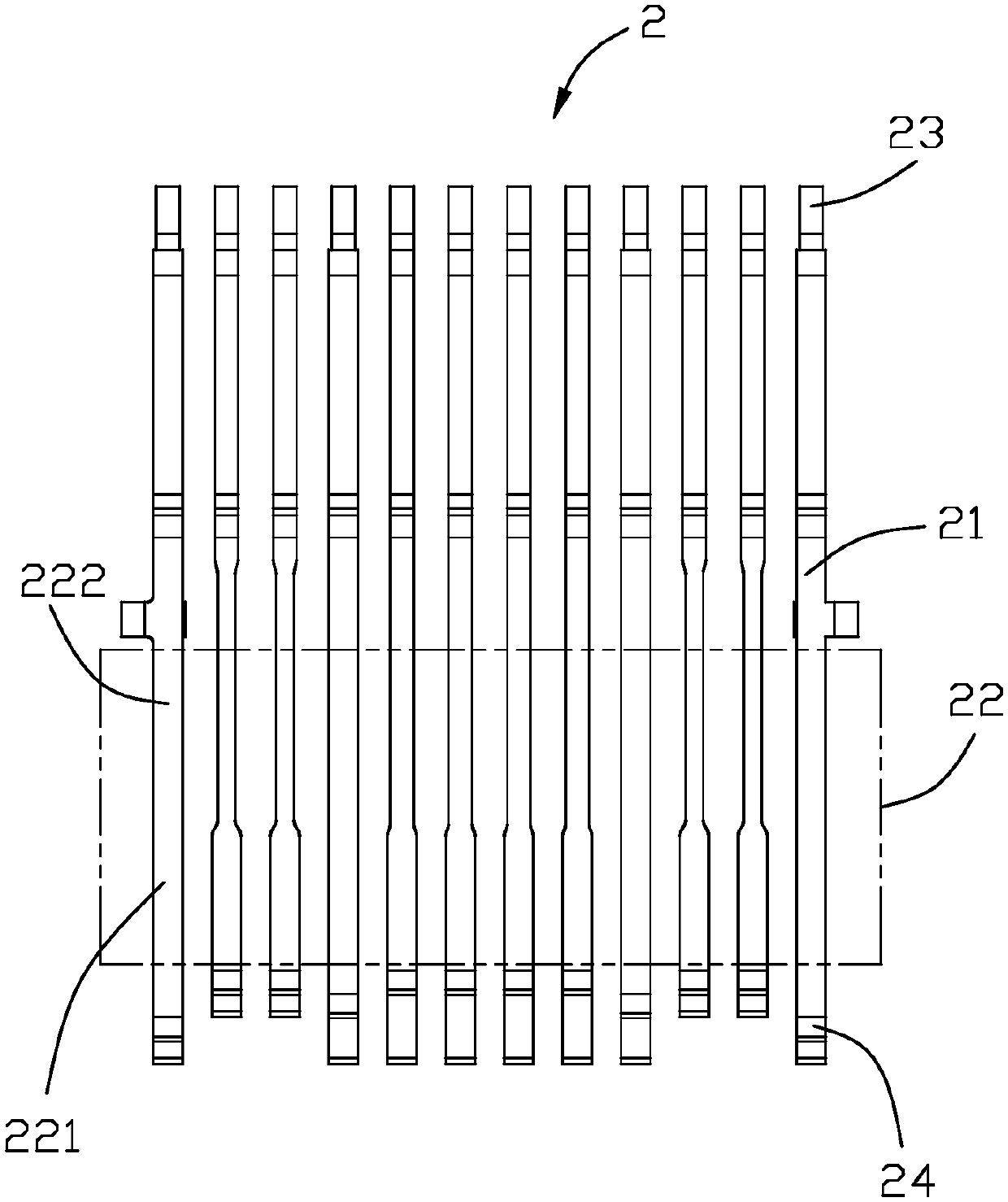

[0023] refer to Figure 1 to Figure 3 As shown, the insulating body 1 includes a base portion 11 and a tongue portion 12 extending forward from the base portion 11 . The conductive terminal 2 includes a holding portion 21 held on the base portion 11, a contact portion 22 extending forward from the holding portion 21 and exposed to the tongue portion 12, and a contact portion 22 extending backward from the holding portion. The welding part 23 of the base part 11 . The tongue portion 12 includes two surfaces facing up and down, and the two rows of conductive terminals 2 are respectively arranged on the two surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com