Preparation method for flexible rubber neodymium iron boron magnet with high filling ratio

A technology of rubber NdFeB and NdFeB, which is applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., can solve the problems of rubber NdFeB magnets with poor mechanical properties, small filling volume, and poor performance. Achieve the effects of improving mechanical properties, magnetic properties, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

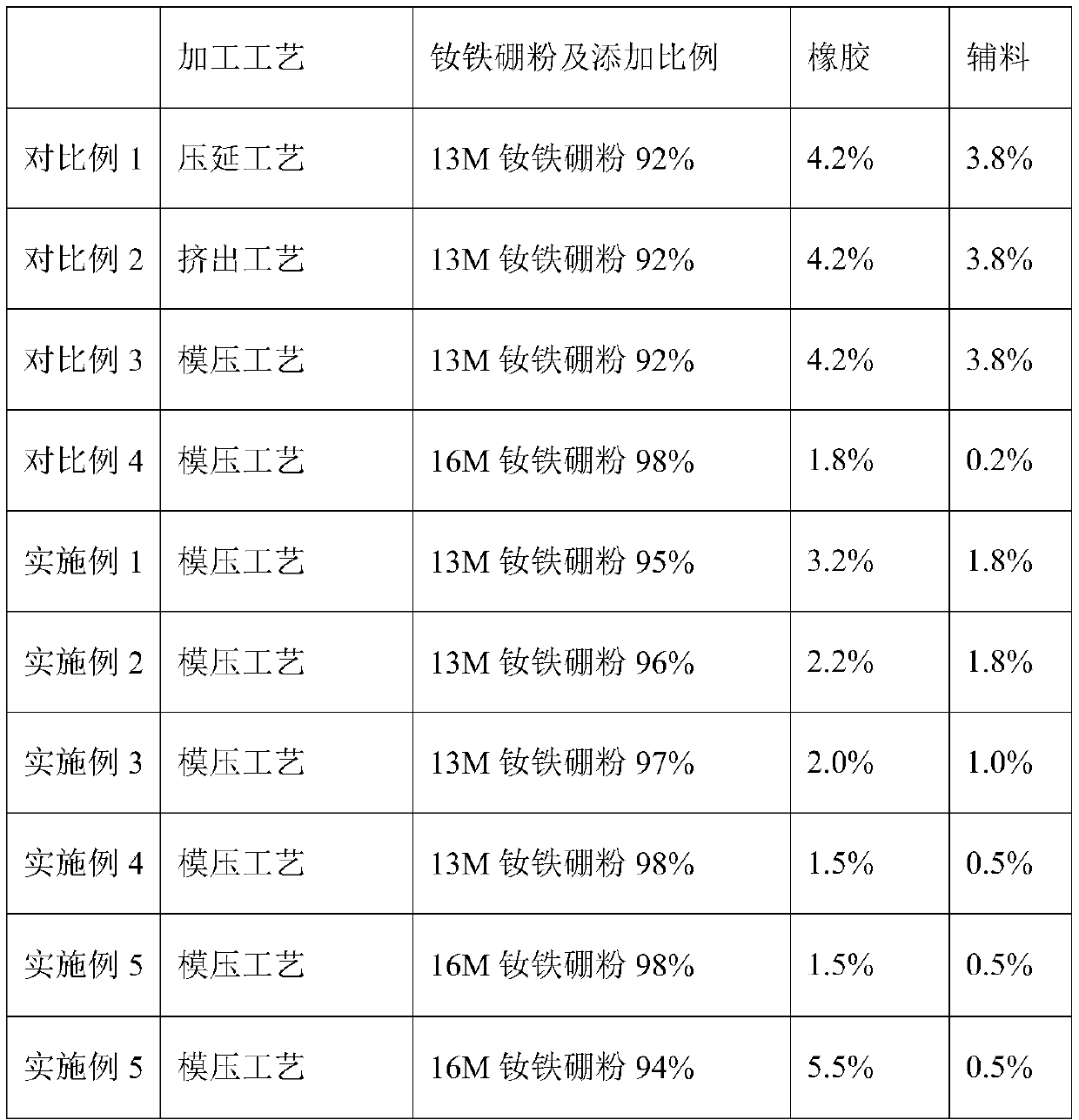

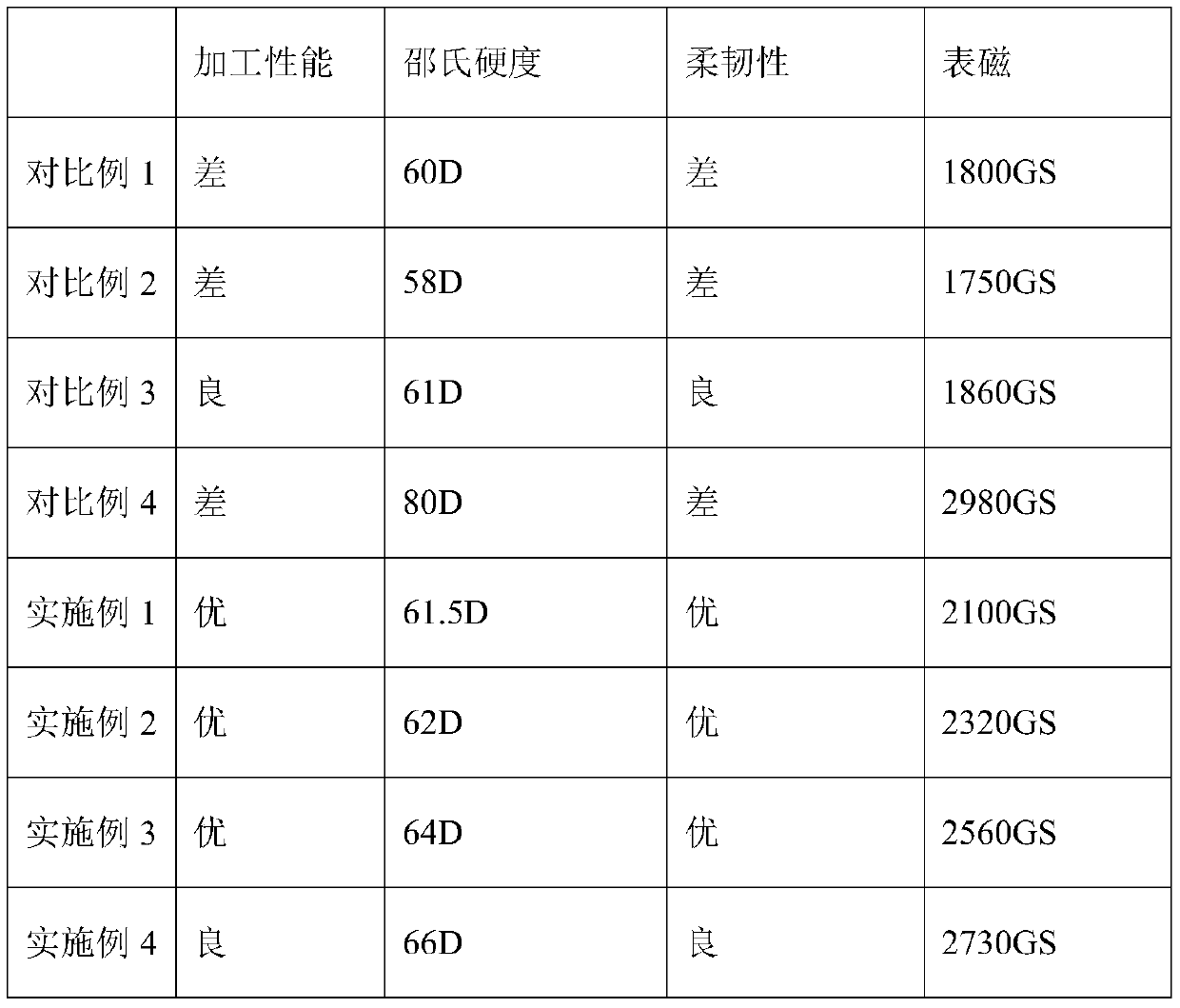

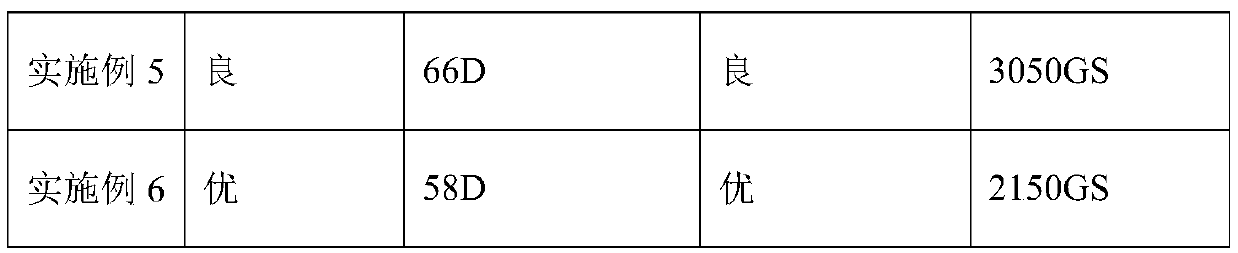

Examples

Embodiment 1

[0040] (S.1) Surface modification: (1) Degreasing and degreasing: add NdFeB powder with a maximum magnetic energy product of 5MGOe into the acidic washing solution, pass air into it to stir the NdFeB powder, and treat at 45°C for 30min Afterwards, filter and wash to neutrality to obtain oil-free NdFeB powder; wherein, each 1L of acidic lotion contains 30ml of concentrated hydrochloric acid with a concentration of 36%, 10g of boric acid, 12g of sodium dodecylbenzenesulfonate and hexamethylene Tetramine 2g;

[0041] (2) Surface phosphating: immerse non-greasy NdFeB powder in phosphating solution, phosphating at 30°C for 15 minutes, filter, wash and dry to obtain NdFeB powder with phosphating film on the surface; The chemical solution contains 90g of zinc dihydrogen phosphate, 15g of phosphoric acid, 4g of ammonium molybdate, 10g of hydrogen peroxide, 4g of sodium borate, 4g of tartaric acid and 0.5g of potassium fluoride;

[0042] (3) Coupling agent treatment: Add 95 parts of N...

Embodiment 2

[0047] The difference from Example 1 is that the addition ratio of surface modified NdFeB powder and rubber is changed, surface modified NdFeB powder: 96%, NBR: 2.2%, sulfur 0.8%, antioxidant RD 0.5% , Epoxidized soybean oil 0.5%. See Table 1 for details, and see Table 2 for the magnetic properties of the prepared rubber magnets.

Embodiment 3

[0049] (S.1) Surface modification: (1) Degreasing and degreasing: add NdFeB powder with a maximum energy product of 12 into the acidic washing solution, pass air into it to stir the NdFeB powder, and treat at 50°C for 30 minutes Filter and wash until neutral to obtain oil-free NdFeB powder; each 1L of acidic lotion contains 50ml of 36% concentrated hydrochloric acid, 3g of boric acid, 15g of sodium dodecylbenzenesulfonate and hexamethylenetetramine 1g;

[0050] (2) Surface phosphating: immerse non-greasy NdFeB powder in phosphating solution, phosphating at 40°C for 30 minutes, filter, wash and dry to obtain NdFeB powder with phosphating film on the surface; The chemical solution contains 95g of zinc dihydrogen phosphate, 20g of phosphoric acid, 4g of ammonium molybdate, 12g of hydrogen peroxide, 5g of sodium borate, 5g of tartaric acid and 1g of potassium fluoride;

[0051] (3) Coupling agent treatment: add NdFeB powder with phosphating film on the surface to the ethanol solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com