Tunnel fire-fighting robot and fire-fighting device

A fire-fighting robot and fire-fighting device technology, used in safety devices, dust-proof, fire prevention and other directions, can solve the problems of low fire-fighting efficiency, poor flexibility, slow speed, etc., and achieve good fire-fighting effect, easy to move, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

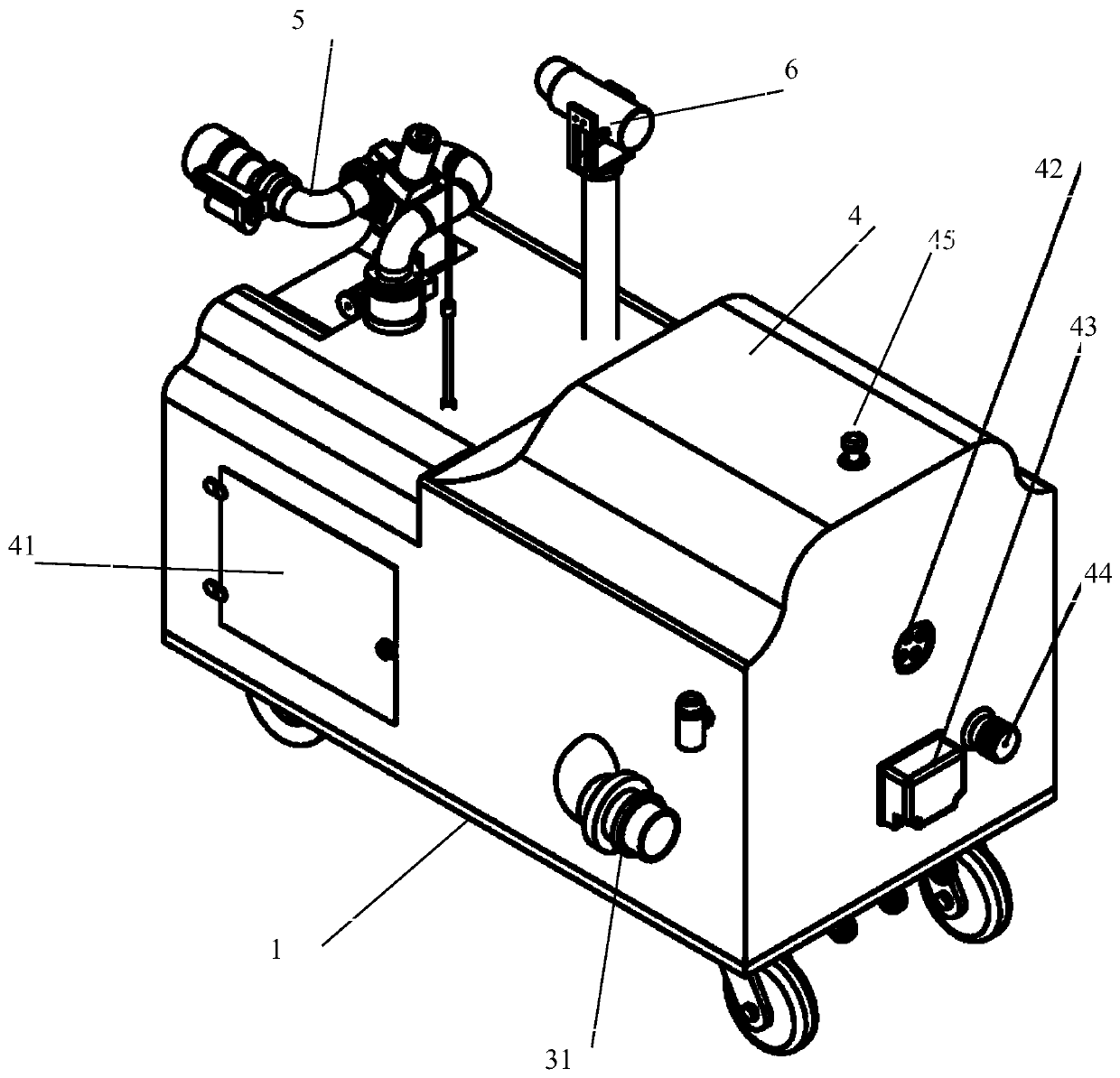

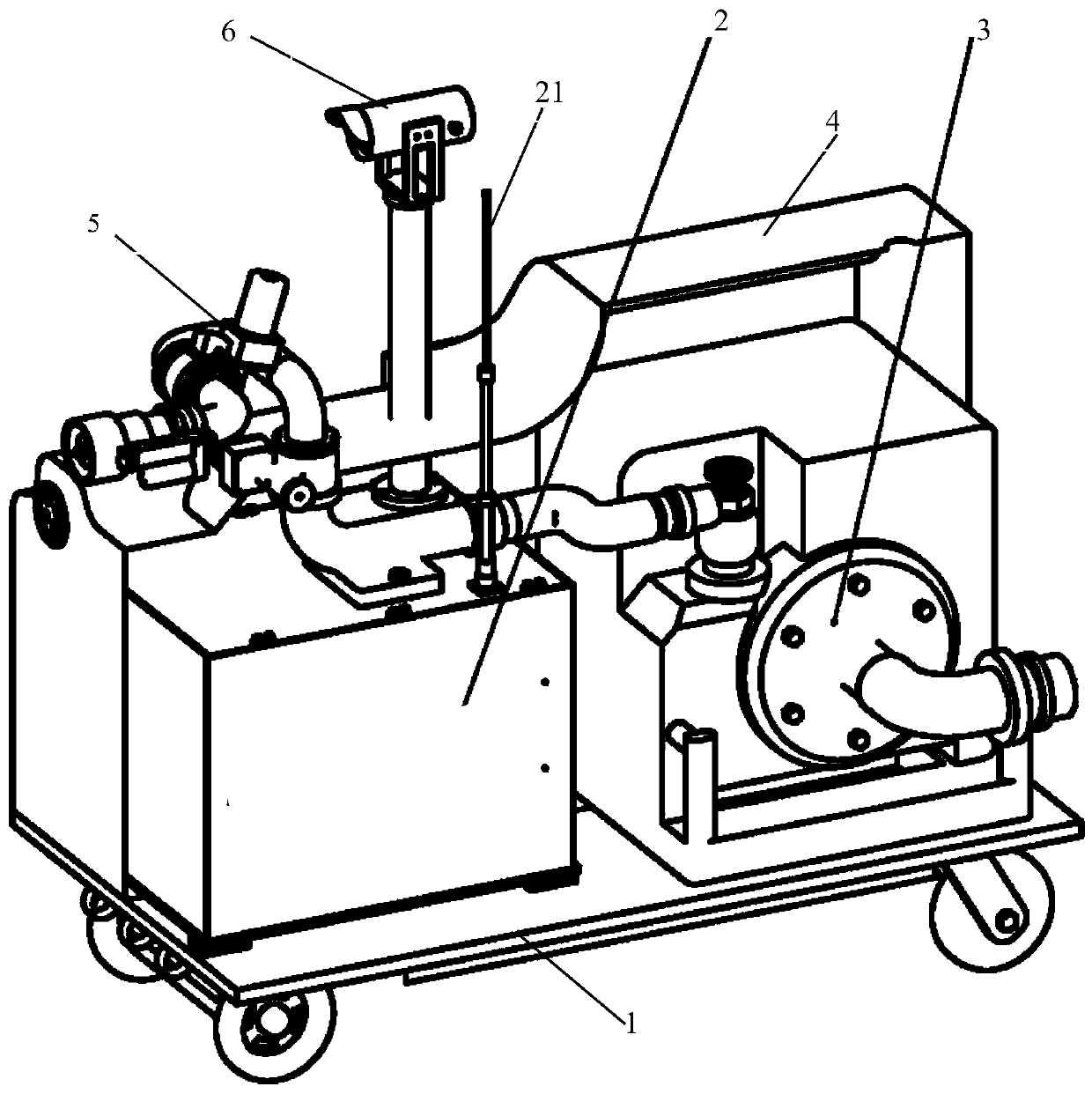

[0023] A tunnel fire-fighting robot, comprising a wheeled chassis 1, a control cabinet 2 and a booster pump 3 arranged on the chassis, a shield 4 for shielding the control cabinet and the booster pump, and a The water cannon 5 on the shield, the water inlet of the water cannon communicates with the water outlet of the booster pump.

[0024] The chassis of the tunnel fire-fighting robot of the present invention can make the robot easy to move, has a braking function and ensures that the parts of the robot are firm and reliable, and the fire-fighting robot adds a booster component, and the system can pressurize itself to ensure that the fire-fighting water has sufficient fire-fighting pressure. Water Cannon, which makes the water cannon have a greater range. Especially when the fire is difficult to approach and the fire is large, it is very useful. The tunnel fire robot is small in size, high in efficiency, and good in firefighting effect. It replaces the original manual firefig...

Embodiment 2

[0030] Preferably, the shield is provided with a spray head in communication with the cooling pump or the booster pump. The self-spray cooling method is adopted to reduce the problems of the tunnel fire-fighting robot itself. It can make it as close to the fire source as possible, or pass through the fire source for multi-point rescue. Flow grooves are designed on the outer surface of the shield to increase the residence time of the cooling water and improve the temperature control effect.

Embodiment 3

[0032] It also includes a high-temperature-resistant camera 6 communicating with the controller in the control cabinet, and a remote controller wirelessly communicating with the controller in the control cabinet. The remote controller is provided with a display screen.

[0033] The wireless remote operating system based on the controller adopts the remote operation mode to carry out fire fighting and fire fighting operations. The remote operating system includes video transmission and display, and can perform real-time operation and fire-fighting operations of fire-fighting robots within the range of 1KM, which greatly improves the fire-fighting personnel. At the same time, in order to facilitate the transmission of signals, corresponding antennas, such as high temperature resistant antennas, can be used by operators from a long distance to ensure the safety of personnel.

[0034] It also includes a lighting mechanism 42 and drag rings arranged at the front and rear of the chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com