A method for preparing high-strength, toughness, and biocorrosion-resistant magnesium alloy pipes by baking

A bio-corrosion and magnesium alloy technology, applied to high-toughness and bio-corrosion-resistant magnesium alloy pipes, to prepare fields with high yield strength, which can solve the problem of inability to effectively improve the yield ratio and toughness simultaneously, endangering the bio-corrosion resistance of pipes, There is no improvement in mechanical properties, etc., to achieve the effect of improving mechanical properties and bio-corrosion resistance, excellent bio-corrosion resistance, and increasing safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

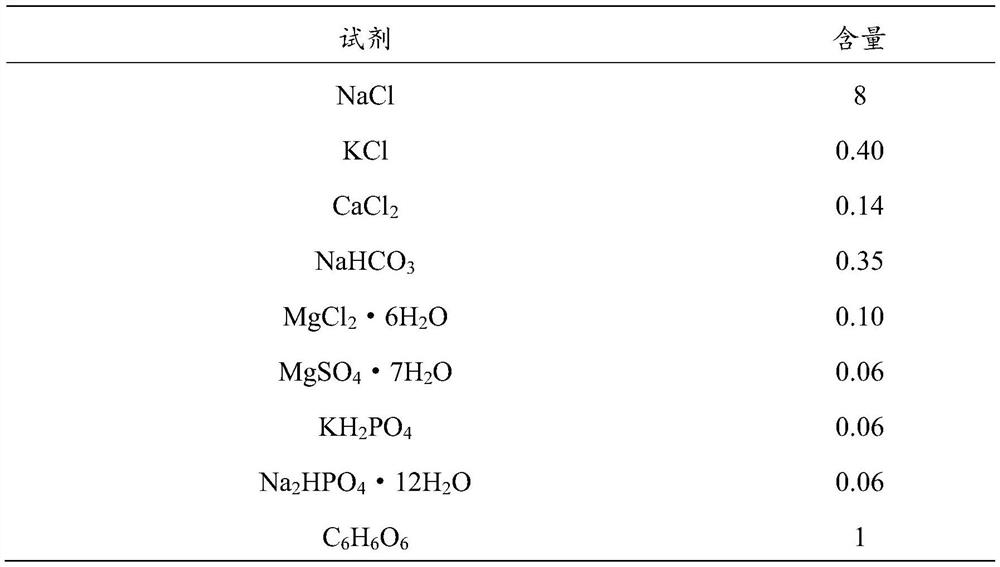

[0018] In this embodiment, the raw material is Mg-0.5Ca-0.05Y (atomic percentage), and the semi-continuous casting method is used to cast a cylindrical magnesium alloy ingot with an outer diameter of 4.2 mm. Pulling, the processing rate of each pass is not more than 15%, and the intermediate annealing and water quenching are carried out at 420 ° C for 50 minutes after each drawing. After the last pass, a pipe with an outer diameter of 1.8mm and a wall thickness of 0.25mm was obtained, which was baked and water-quenched at 200°C for 40min. As a comparison, another sample was still annealed at 420°C for 50 minutes after the same casting and drawing process without baking. Subsequently, the mechanical properties of the two samples were tested at room temperature, and the biological environment immersion test was carried out according to the ASTM G31-72 standard in Hank’s simulated body fluid (see Table 1 for composition) at 37°C. The test results are shown in Table 2.

[0019] ...

Embodiment 2

[0025] In this embodiment, the raw material is Mg-0.9Zn-0.07Y (atomic percentage), and the semi-continuous casting method is used to cast a cylindrical magnesium alloy ingot with an outer diameter of 3 mm. After solution treatment, several times of drawing are carried out at room temperature. , The processing rate of each pass is not more than 15%, and the intermediate annealing and water quenching are carried out at 390°C for 80min after each drawing. After the last pass, a pipe with an outer diameter of 1.5 mm and a wall thickness of 0.15 mm was obtained, which was baked at 190° C. for 30 minutes and quenched in water. As a comparison, another sample was still annealed at 390°C for 80 minutes after the same casting and drawing process without baking. Subsequently, the mechanical properties of the two samples were tested at room temperature, and the biological environment immersion test was carried out according to the ASTM G31-72 standard in Hank’s simulated body fluid (see ...

Embodiment 3

[0030] In this embodiment, the raw material is Mg-1.2Sn-0.1Y (atomic percentage), and the semi-continuous casting method is used to cast a cylindrical magnesium alloy ingot with an outer diameter of 4.5 mm. After solution treatment, it is drawn several times at room temperature. Pulling, the processing rate of each pass is not more than 15%, and the intermediate annealing and water quenching are carried out at 440 ° C for 120 minutes after each drawing. After the last pass, a pipe with an outer diameter of 2.0 mm and a wall thickness of 0.30 mm was obtained, which was baked and water-quenched at 150°C for 60 minutes. As a comparison, another sample was still annealed at 440°C for 120 minutes after the same casting and drawing process without baking. Subsequently, the mechanical properties of the two samples were tested at room temperature, and the biological environment immersion test was carried out according to the ASTM G31-72 standard in Hank’s simulated body fluid (see Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com