A method for catalytic diesel hydrogenation conversion to aromatics

A catalytic diesel and hydrogenation conversion technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of poor selectivity of single-ring aromatics, achieve high selectivity of single-ring aromatics, reduce processing costs, and improve Effect of Hydrogen Utilization Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

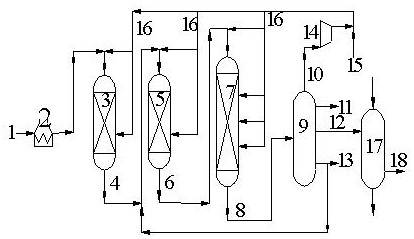

[0040] Embodiment 1~3 all adopts flow process of the present invention, figure 1 The combined process flow shown. After being heated by the heating furnace, the high-aromatic catalytic diesel oil is mixed with circulating hydrogen and enters the I hydrorefining reaction zone for hydrodesulfurization, polycyclic aromatic hydrocarbons selective hydrogenation saturation and other reactions; the obtained oil is mixed with circulating hydrogen and enters II hydrorefining reaction zone The reaction zone carries out further hydrodesulfurization reaction and aromatics selective reaction; the obtained oil is mixed with circulating hydrogen and enters the hydrocracking reaction area for hydrocarbon hydroconversion reaction; the obtained oil is separated and fractionated to obtain gas, pumice Naphtha, heavy naphtha, diesel fractions. Part of the diesel is recycled back to the II hydrorefining reaction zone, and part of the diesel is sent out of the unit. The gas is recycled through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com