Ceramic membrane of loaded nanometer wire photocatalyst and preparation method thereof

A technology of photocatalyst and ceramic membrane, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

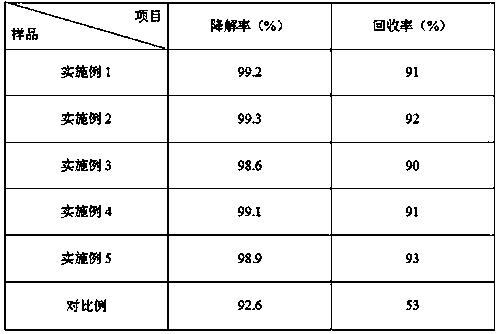

Examples

Embodiment 1

[0034] A ceramic membrane loaded with nanoscale photocatalysts, the ceramic membrane loaded with nanoscale materials includes a ceramic membrane carrier, a catalytically active component and a modifier, the ceramic membrane carrier is an alumina membrane carrier in a hollow fiber configuration, and the diameter of the ceramic membrane carrier The thickness is 1mm, the thickness is 0.1mm, the average pore size is 50nm, and the catalytic active component is coated with SnO 2 Titanium dioxide nanoparticles, the catalytic active component is prepared from the following raw materials in parts by weight: 10 parts of nano-titanium dioxide, SnCl 4 100 parts of solution, 1 part of urea and hydrochloric acid solution, SnCl 4 The concentration of the solution is 15mmol / L.

[0035] The modifier consists of the following components in parts by weight: 10 parts of nano-zinc oxide, 60 parts of solvent and 0.5 part of triethanol, and the solvent is a mixture of acetone and ethylene glycol me...

Embodiment 2

[0043] A ceramic membrane loaded with nanoscale photocatalysts, the ceramic membrane loaded with nanoscale materials includes a ceramic membrane carrier, a catalytically active component and a modifier, the ceramic membrane carrier is a zirconia membrane carrier in a flat configuration, the diameter of the ceramic membrane carrier The thickness is 10mm, the thickness is 0.5mm, the average pore size is 100nm, and the catalytic active component is coated with SnO 2 Titanium dioxide nanoparticles, the catalytic active component is prepared from the following raw materials in parts by weight: 12 parts of nano-titanium dioxide, SnCl 4 110 parts of solution, 2 parts of urea and hydrochloric acid solution, SnCl 4 The concentration of the solution was 17mmol / L.

[0044] The modifier is composed of the following components in parts by weight: 12 parts of nano-zinc oxide, 70 parts of solvent and 0.6 part of triethanol, and the solvent is a mixture of acetone and ethylene glycol methyl ...

Embodiment 3

[0052] A ceramic membrane loaded with nanoscale photocatalysts, the ceramic membrane loaded with nanoscale materials includes a ceramic membrane carrier, a catalytically active component and a modifier, the ceramic membrane carrier is a titanium oxide membrane carrier with a single-channel tubular configuration, and the ceramic membrane carrier The diameter is 30mm, the thickness is 1.5mm, the average pore size is 300nm, and the catalytic active component is the surface coated with SnO 2 Titanium dioxide nanoparticles, the catalytic active component is prepared from the following raw materials in parts by weight: 15 parts of nano-titanium dioxide, SnCl 4 125 parts of solution, 3 parts of urea and hydrochloric acid solution, SnCl 4 The concentration of the solution is 20mmol / L.

[0053] The modifier is composed of the following components in parts by weight: 15 parts of nano-zinc oxide, 80 parts of solvent and 0.7 part of triethanol, and the solvent is a mixture of acetone and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com