Coal combustion catalyst with demercuration effects and preparation method thereof

A coal-burning catalyst and catalyst technology, which can be used in fuels, solid fuels, petroleum industries, etc., can solve problems such as human harm, and achieve the effects of reducing emissions, increasing activity, and promoting combustion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

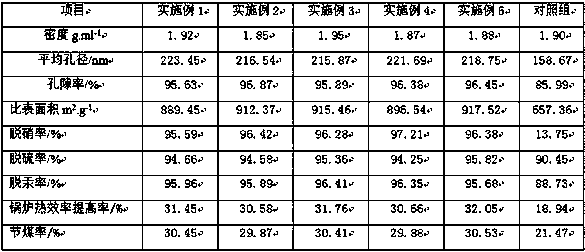

Examples

Embodiment 1

[0026] Grind 15 parts of loofah, 11 parts of rice straw, and 5 parts of corn stalks into 28-mesh powder, soak in 2wt% sodium hydroxide solution for 90 minutes, filter with mesh cloth, wash with distilled water, and finally place in a 68°C refrigerator Dried in a drying oven to obtain pretreated powder;

[0027] The concentration is 0.03mol.L -1 17 parts of cerium nitrate solution, the concentration is 0.005mol.L -1 6.5 parts of yttrium nitrate solution, the concentration is 0.005mol.L -1 4 parts of gadolinium nitrate solution are placed in reaction kettle A, then add 85 parts of dehydrated alcohol, 19 parts of diethanolamine, 7.5 parts of ammonium persulfate and stir and mix to obtain a mixed solution, then add Al 2 o 3 18 parts, 9 parts of ferric nitrate, CuCl 2 7.5 parts were added to the mixed solution, with 2mol.L -1 solution and 2mol.L -1 Strong sodium oxide solution adjusted the pH value to 8.5, then ultrasonicated for 60 minutes under the condition of ultrasonic p...

Embodiment 2

[0031] Grind 16.5 parts of loofah, 10.5 parts of rice straw, and 4.8 parts of corn stalks into 30-mesh powder, soak in 2wt% sodium hydroxide solution for 93 minutes, filter with mesh cloth, wash with distilled water, and finally place in a 70°C refrigerator. Dried in a drying oven to obtain pretreated powder;

[0032] The concentration is 0.03mol.L -1 16 parts of cerium nitrate solution, the concentration is 0.005mol.L -1 7.5 parts of yttrium nitrate solution, the concentration is 0.005mol.L -1 3 parts of gadolinium nitrate solution are placed in reaction kettle A, then add 90 parts of dehydrated alcohol, 19.5 parts of diethanolamine, 6 parts of ammonium persulfate and stir and mix to obtain a mixed solution, then add Al 2 o 3 17 parts, 9.5 parts of ferric nitrate, CuCl 2 7 parts, added to the mixed solution, with 2mol.L -1 solution and 2mol.L -1 Adjust the pH value to 7 with a strong sodium oxide solution, then ultrasonicate for 60 minutes under the conditions of ultras...

Embodiment 3

[0036] Grind 18 parts of loofah, 10 parts of rice straw, and 4 parts of corn stalks into 25-mesh powder, soak in 2wt% sodium hydroxide solution for 100 minutes, filter with mesh cloth, wash with distilled water, and finally place in a 65°C refrigerator Dried in a drying oven to obtain pretreated powder;

[0037] The concentration is 0.03mol.L -1 15 parts of cerium nitrate solution, the concentration is 0.005mol.L -1 6 parts of yttrium nitrate solution, the concentration is 0.005mol.L -1 3.8 parts of gadolinium nitrate solution are placed in reactor A, then add 82 parts of dehydrated alcohol, 18 parts of diethanolamine, 7 parts of ammonium persulfate and stir and mix to obtain a mixed solution, then add Al 2 o 3 16 parts, 8 parts of ferric nitrate, CuCl 2 6.5 parts, added to the mixed solution, with 2mol.L -1 solution and 2mol.L -1 Adjust the pH value to 8 with a strong sodium oxide solution, then ultrasonicate for 60 minutes under the conditions of ultrasonic power of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com