Low-temperature-resistant and heat-conducting insulating resin paint applicable to superconducting insulating material as well as preparation method and application of superconducting insulating material

An insulating material, thermal insulation technology, applied in epoxy resin coatings, carboxyl rubber coatings, polyurea/polyurethane coatings, etc., can solve problems such as low thermal conductivity, damage to superconducting equipment, low temperature resistance, etc. The effect of thermal conductivity, excellent electrical properties, and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a nano-scale modified boron nitride, the preparation method of which is as follows:

[0037]Step 1) First weigh 3 parts of hexagonal boron nitride and add to 50 parts of ethanol solution, and disperse to obtain a milky white liquid for later use. Then configure 100 parts of 5mol / L (0.2g / ml) NaOH aqueous solution (mass fraction is 16.7%) for later use, add the above two solutions into a three-necked flask, stir magnetically under an oil bath at 100°C and condense and reflux for 18 hours , and then the resulting solution was filtered and washed to neutrality, and then dried to obtain modified h-BN (that is, modified boron nitride).

[0038] Step 2) Blend 50 parts of deionized water and 50 parts of isopropanol (deionized water: isopropanol = 1:1), and add 2 parts of modified boron nitride into the blended solution to form a milky white solution. The milky white solution was ultrasonically dispersed for 4 hours (JY92-2D ultrasonic cell pulverizer) ...

Embodiment 2

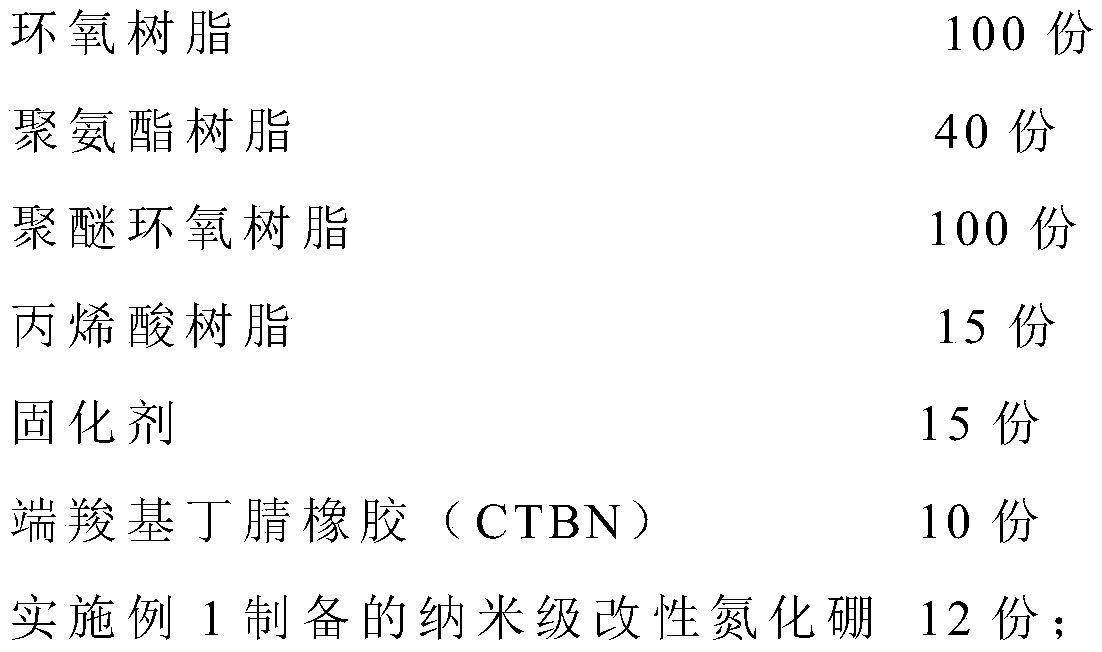

[0040] This embodiment provides a kind of low-temperature-resistant heat-conducting insulating resin varnish suitable for superconducting insulating materials, and its raw materials include:

[0041]

[0042] Wherein, the epoxy resin is composed of 30 parts of bisphenol A type epoxy resin, 30 parts of bisphenol F type epoxy resin and 40 parts of hyperbranched epoxy resin;

[0043] The curing agent consisted of 5 parts polyamide 650, 5 parts diethyltoluenediamine and 5 parts methylnadic anhydride.

[0044] The preparation method of the above-mentioned low-temperature-resistant heat-conducting insulating resin varnish suitable for superconducting insulating materials comprises the following steps:

[0045] (1) Weigh each raw material according to the formula, add epoxy resin into the reaction vessel, heat up to 100°C, and vacuumize for 30 minutes;

[0046] (2) adding nanoscale modified boron nitride, mixing and stirring for 2h;

[0047] (3) Add polyurethane resin to keep th...

Embodiment 3

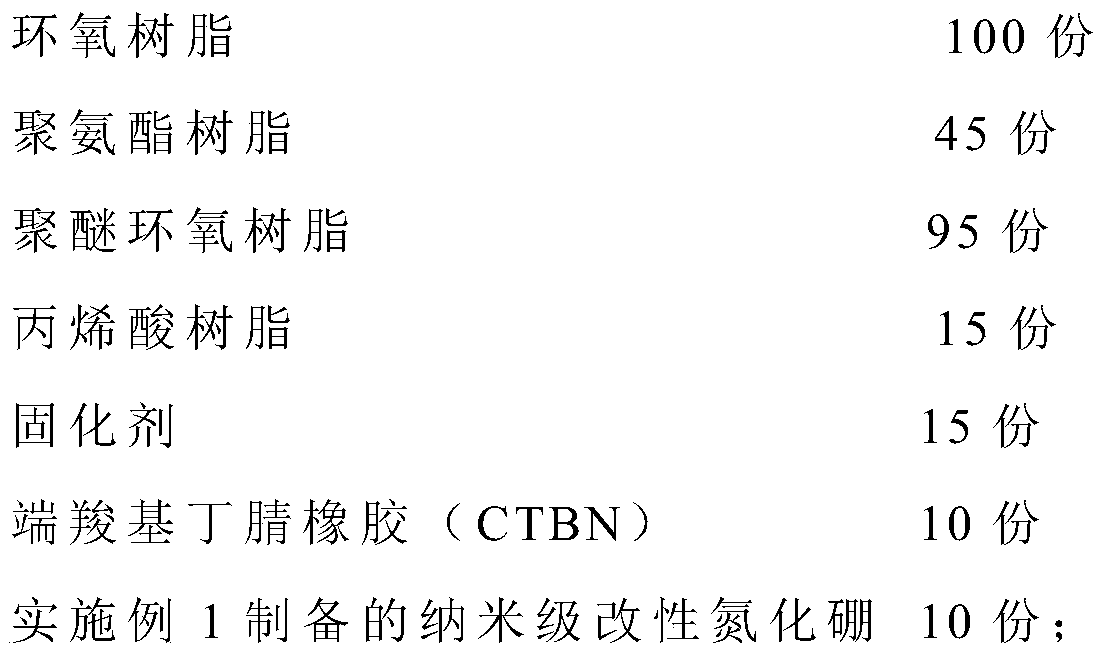

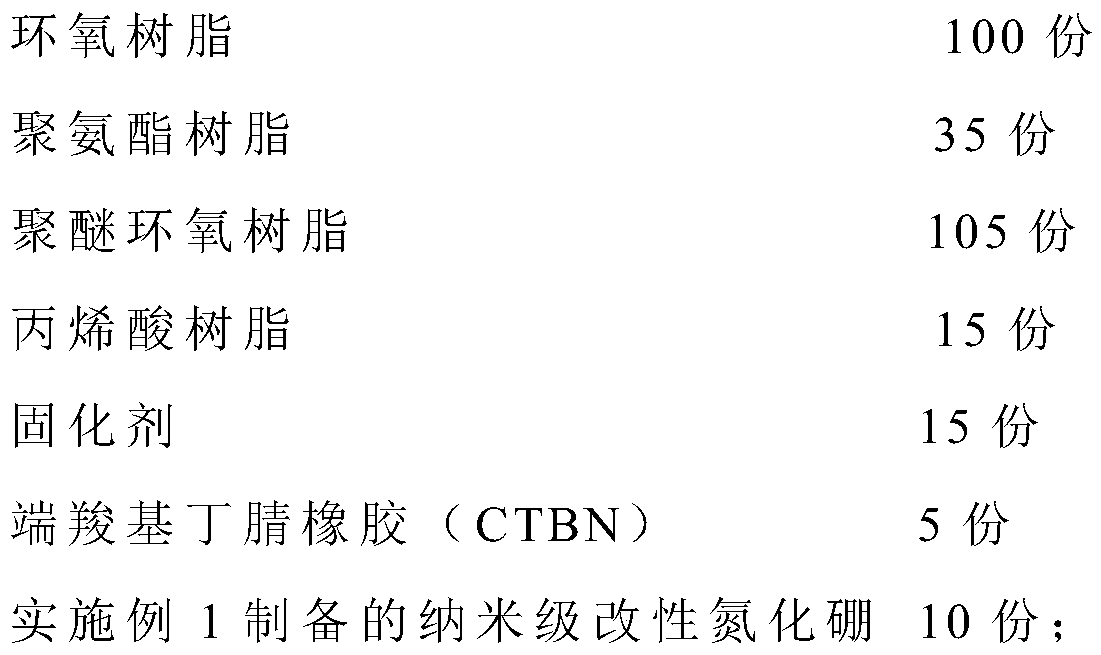

[0052] This embodiment provides a kind of low-temperature-resistant heat-conducting insulating resin varnish suitable for superconducting insulating materials, and its raw materials include:

[0053]

[0054] Others are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com