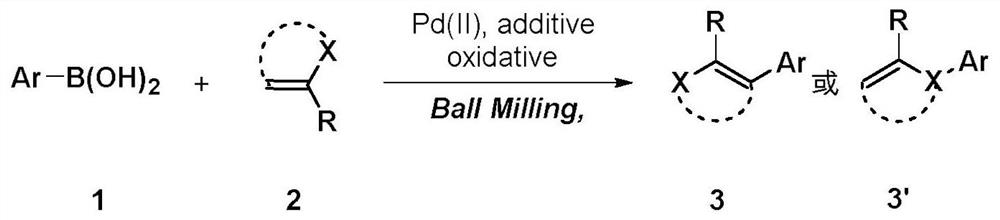

A kind of preparation method of inactive olefin aryl compound

A compound and olefin technology, applied in the preparation of organic compounds, chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons, etc., can solve the problem of olefin arylates that are not easy to generate a single structure, and there are no inactive olefin arylates , less research on arylation reaction, etc., to achieve the effects of reducing environmental pollution and safety hazards, good promotion prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of methyl 1-cyclopentene-1-carboxylate-5-phenyl

[0039] Phenylboronic acid (60.0 mg, 0.5 mmol), methyl 1-cyclopentene-1-carboxylate (63.0 mg, 0.5 mmol), and Pd(OAc) were added to a 50 mL stainless steel grinding jar 2 (11.2mg, 0.05mmol), DDQ (56.7mg, 0.25mmol), trichloroacetic acid (81.5mg, 0.5mmol), then add 2 stainless steel balls with a diameter of 12mm, tighten the grinding jar, and put it into a pendulum grinder , milled at a frequency of 20 Hz for 30 minutes. The progress of the reaction was followed by TLC (sample dissolved in ethyl acetate). After the reaction, the whole reaction mixture was poured out from the grinding tank, the stainless steel ball was taken out, and petroleum ether and ethyl acetate (volume ratio 100:1) were used as eluents, and the mixture was separated by silica gel column chromatography according to the Rf value, The obtained target fraction eluent was evaporated to remove the solvent to obtain methyl 1-phenyl-2-cy...

Embodiment 2

[0040] Example 2 Preparation of methyl 1-cyclopentene-1-carboxylate-5-phenyl

[0041] Phenylboronic acid (60.0 mg, 0.5 mmol), methyl 1-cyclopentene-1-carboxylate (15.8 mg, 0.125 mmol), and Pd(TFA) were added to a 25 mL stainless steel grinding jar 2 (16.6mg, 0.05mmol), DDQ (113.5mg, 0.5mmol), trichloroacetic acid (4.1mg, 0.025mmol), then add 1 stainless steel ball with a diameter of 14mm, tighten the grinding jar, and put it into the vibrating grinder , milled at a frequency of 20 Hz for 30 minutes. The progress of the reaction was followed by TLC (sample dissolved in ethyl acetate). After the reaction, the whole reaction mixture was poured out from the grinding tank, the stainless steel ball was taken out, and petroleum ether and ethyl acetate (volume ratio 100:1) were used as eluents, and the mixture was separated by silica gel column chromatography according to the Rf value, The obtained target fraction eluate was evaporated to remove the solvent to obtain methyl 1-phenyl...

Embodiment 3

[0042] Example 3 Preparation of methyl 1-cyclopentene-1-carboxylate-5-phenyl

[0043] Phenylboronic acid (60.0 mg, 0.5 mmol), methyl 1-cyclopentene-1-carboxylate (31.5 mg, 0.25 mmol), and Pd(OAc) were added to a 50 mL stainless steel grinding jar 2 (11.2 mg, 0.05 mmol), DDQ (113.5 mg, 0.5 mmol), acetic acid (0.6 mg, 0.01 mmol), then 4 stainless steel balls with a diameter of 6 mm were added, the grinding jar was tightened, and placed in a pendulum grinding apparatus, Grind for 30 minutes at a frequency of 10 Hz. The progress of the reaction was followed by TLC (sample dissolved in ethyl acetate). After the reaction, the whole reaction mixture was poured out from the grinding tank, the stainless steel ball was taken out, and petroleum ether and ethyl acetate (volume ratio 100:1) were used as eluents, and the mixture was separated by silica gel column chromatography according to the Rf value, The obtained target fraction eluent was evaporated to remove the solvent to obtain me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com