Automotive PVC stone chip resistant paint and preparation method thereof

A technology for anti-stone impact and automobile, applied in the direction of coating, etc., can solve the problems of poor dispersion of inorganic foaming agent, easy penetration and retention of moisture, and reduced corrosion resistance, so as to achieve increased adhesion, uniform bubble size, and high resistance to corrosion. Corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

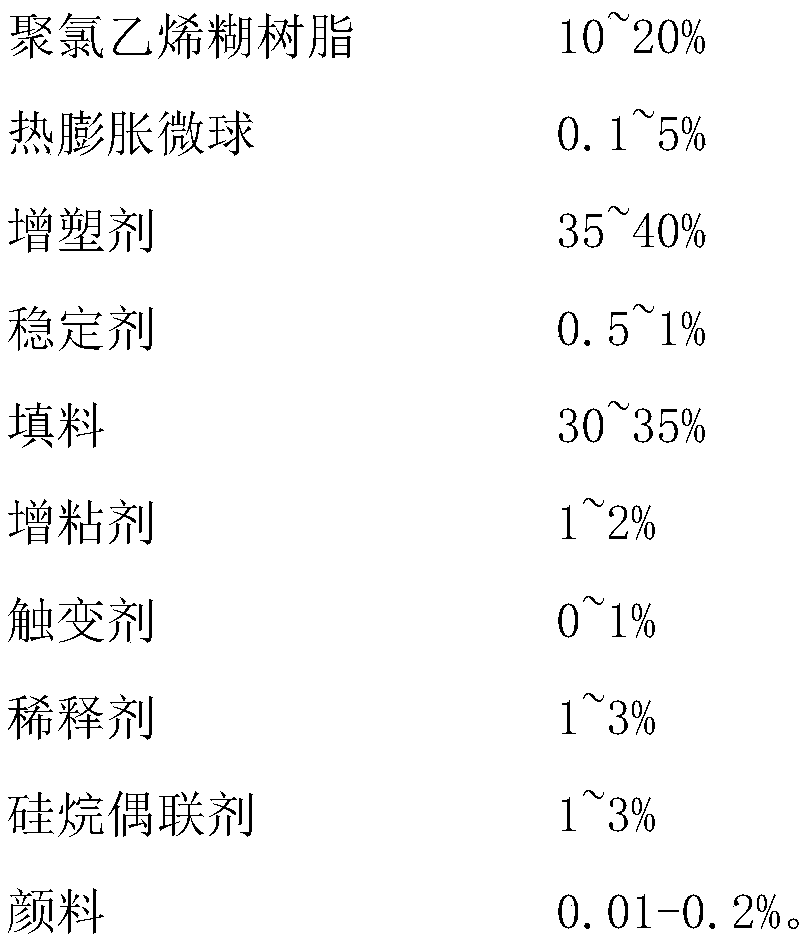

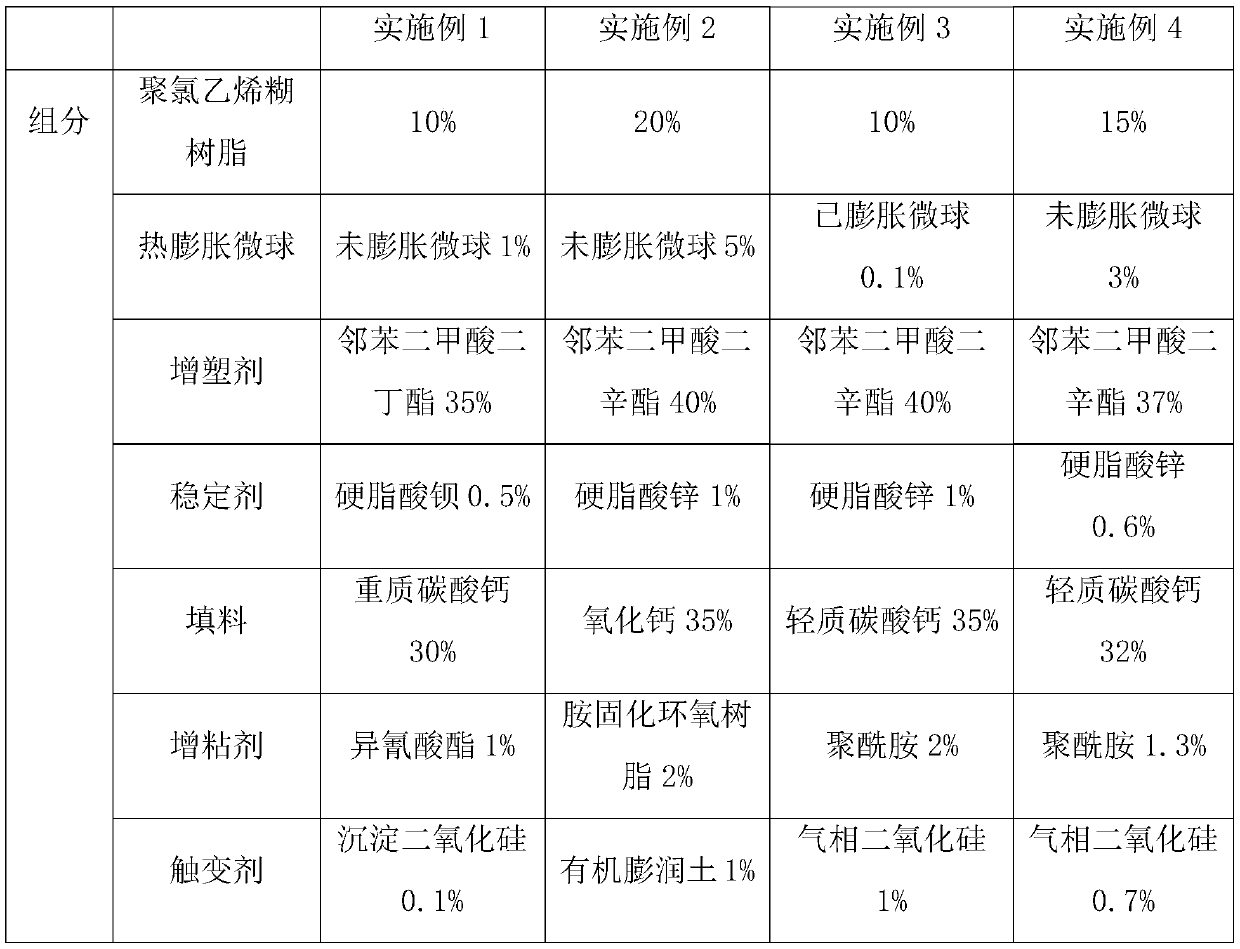

[0039] This example provides an automotive PVC anti-stone chip coating and its preparation method and application. The components are shown in Table 1.

[0040] (1) Mix and stir 1% diluent D80 and 35% plasticizer dibutyl phthalate until the solution is transparent and uniform;

[0041] (2) Add 10% polyvinyl chloride paste resin to (1) and stir to disperse;

[0042] (3) Add 0.5% stabilizer barium stearate, 1% tackifier isocyanate, 0.1% thixotropic agent precipitated silica, 30% filler ground calcium carbonate, 0.01% pigment carbon black to (2) and stir evenly ;

[0043] (4) Slowly add 1% unexpanded microspheres, 1% silane coupling agent vinyltriethoxysilane to (3), fully stir and mix, and vacuumize and stir to remove the air bubbles in the product to obtain the obtained The car PVC anti-stone impact coating.

[0044](5) Take a certain amount of PVC anti-stone chip coating in the mold, and slowly scrape it from one side to the other side with a scraper to ensure that the coat...

Embodiment 2

[0047] This example provides an automotive PVC anti-stone chip coating and its preparation method and application. The components are shown in Table 1.

[0048] (1) Mix and stir 3% diluent D80 and 40% dioctyl phthalate until the solution is transparent and uniform;

[0049] (2) Add 20% polyvinyl chloride paste resin to (1) and stir to disperse;

[0050] (3) Add 1% stabilizer zinc stearate, 2% tackifier amine cured epoxy resin, 1% thixotropic agent organic bentonite, 35% filler calcium oxide, 0.1% pigment carbon black, 0.05 %titanium dioxide is stirred evenly;

[0051] (4) Slowly add 5% unexpanded microspheres and 3% silane coupling agent vinyl tris(β-methoxyethoxy)silane to (3), stir well, and vacuumize to remove the product The air bubbles in the car PVC anti-stone chip coating are obtained.

[0052] (5) Take a certain amount of PVC anti-stone chip coating in the mold, and slowly scrape it from one side to the other side with a scraper to ensure that the coating film is sm...

Embodiment 3

[0055] This example provides an automotive PVC anti-stone chip coating and its preparation method and application. The components are shown in Table 1.

[0056] (1) Mix and stir 3% diluent D50 and 40% dioctyl phthalate until the solution is transparent and uniform;

[0057] (2) Add 10% polyvinyl chloride paste resin to (1) and stir to disperse;

[0058] (3) Add 1% stabilizer zinc stearate, 2% tackifier polyamide, 1% thixotropic agent fumed silica, 35% filler light calcium carbonate, 0.2% pigment carbon black to (2) and stir Uniform;

[0059] (4) Slowly add 0.1% expanded microspheres and 3% silane coupling agent vinyltrimethoxysilane to (3), fully stir and mix, and vacuumize and stir to remove air bubbles in the product to obtain the described Automotive PVC anti-stone impact coatings.

[0060] (5) Take a certain amount of PVC anti-stone chip coating in the mold, and slowly scrape it from one side to the other side with a scraper to ensure that the coating film is smooth and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com