Acid controlled degradation ketal-type alicyclic epoxy resin, preparation method and application

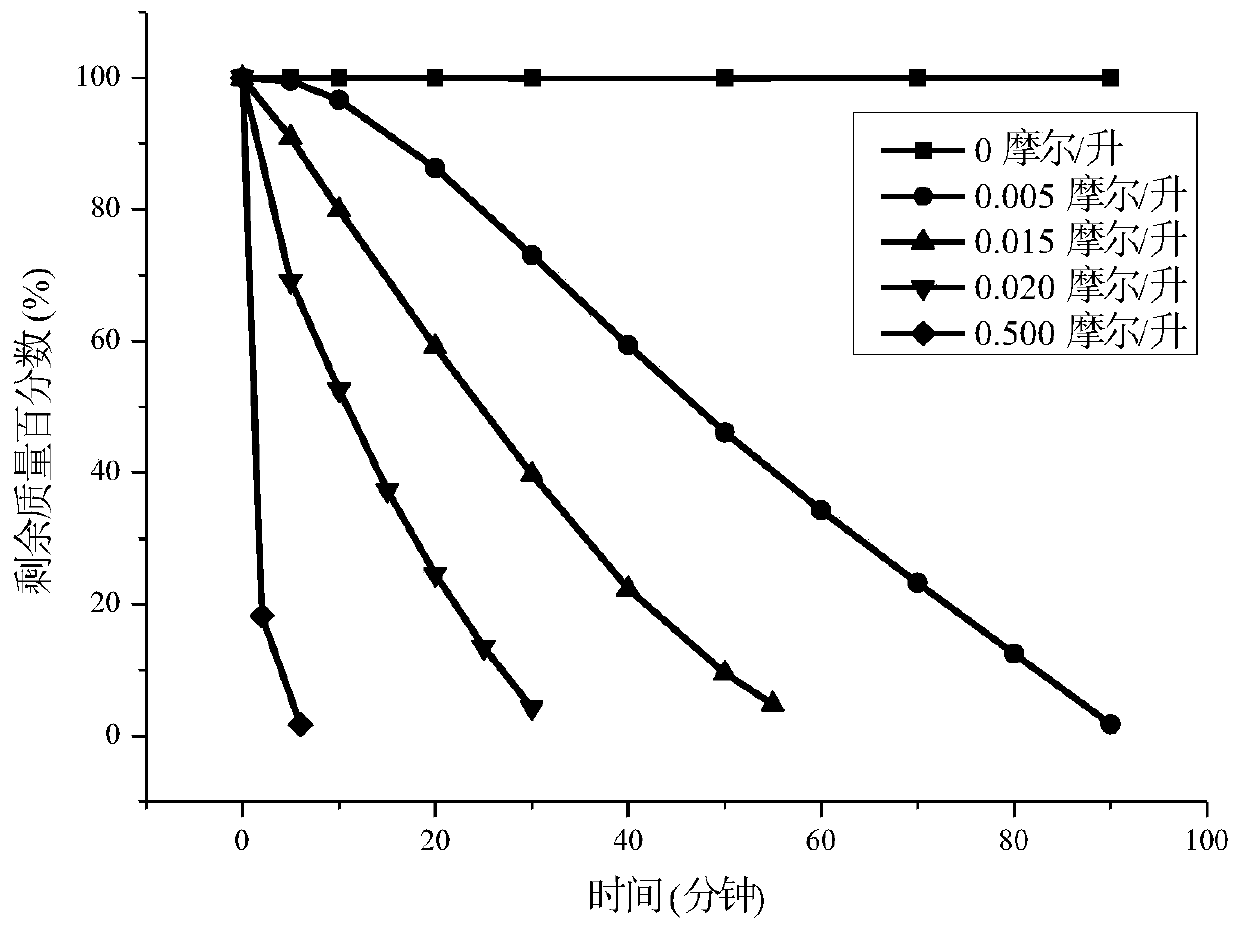

An epoxy resin and cycloaliphatic technology, which is used in the field of acid-controlled degradation of ketal-type cycloaliphatic epoxy resin, preparation and application, can solve the problems of inability to melt microorganisms, degradation, insolubility, etc., and achieve degradation time can be achieved Adjustment, low temperature degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of bifunctional ketal-based cycloaliphatic epoxy resin:

[0039] (1) Under ice-water bath conditions, add 44.868 grams of 3-cyclohexene-1-methanol, 20 grams of 5A molecular sieves, 1.902 grams of p-toluenesulfonic acid monohydrate, 150 Add 9.814 g of cyclohexanone dropwise to 1 ml of n-hexane, stir and react for 12 hours to terminate the reaction, wash the product with 15% NaO in 1 hour aqueous solution, then wash with deionized water until neutral, dry with anhydrous magnesium sulfate, and filter , concentration, and distillation under reduced pressure to obtain an intermediate product with a yield of 60%.

[0040] (2) 45 grams of potassium persulfate compound salt and 0.06 grams of ethylenediaminetetraacetic acid were dissolved in 240 milliliters of deionized water to prepare an epoxidation reagent solution. Under ice-water bath conditions, in a 1000 ml four-neck flask equipped with a mechanical stirrer, a thermometer, and a constant pressure dropping fun...

Embodiment 2

[0043] Preparation of bifunctional ketal-based cycloaliphatic epoxy resin:

[0044] (1) At -15°C, add 28.043 grams of 3-cyclohexene-1-methanol, 37.5 grams of calcium sulfate, 2.403 grams of methanesulfonic acid, and 375 milliliters of toluene into a 500 milliliter three-necked flask equipped with mechanical stirring and a thermometer. 12.2675 grams of cyclohexanone was added dropwise, and the reaction was terminated after stirring for 24 hours. The product was washed with 15% NaO in an aqueous solution for 24 hours, and then washed with deionized water to neutrality, dried with anhydrous magnesium sulfate, filtered, and concentrated. Distillation under reduced pressure gave an intermediate product.

[0045](2) Dissolving 57.2 grams of m-chloroperoxybenzoic acid in 200 milliliters of dichloromethane was prepared as an epoxidation reagent solution. Under the condition of -25°C, in a 500 ml four-necked bottle equipped with mechanical stirring, a thermometer, and a constant press...

Embodiment 3

[0047] Preparation of bifunctional ketal-based cycloaliphatic epoxy resin:

[0048] (1) Under the condition of 15°C, add 70.106 grams of 3-cyclohexene-1-methanol, 50 grams of copper sulfate, 12.136 grams of sulfamic acid, and 187.5 milliliters of benzene in a 500 milliliter three-necked flask equipped with mechanical stirring and a thermometer. 12.2675 grams of cyclohexanone was added dropwise, and the reaction was terminated after stirring for 48 hours. The product was first washed with 15% NaO aqueous solution for 1 hour, and then washed with deionized water until neutral, dried with anhydrous magnesium sulfate, filtered, concentrated, and decompressed. Distillation gave an intermediate product.

[0049] (2) 72 grams of p-nitroperoxybenzoic acid was dissolved with 200 milliliters of N,N-dimethylformamide to prepare an epoxidation reagent solution. Under the condition of 25°C, add 33.49 g of the intermediate product in a 500 ml four-necked bottle equipped with mechanical sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com