Match grinding and finish lapping technology for lining and piston in speed controller

A speed governor and bushing technology, which is applied in the direction of grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problem that the bushing and piston cannot meet the required matching accuracy, achieve tight cooperation, increase service life, and reduce oil leakage volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

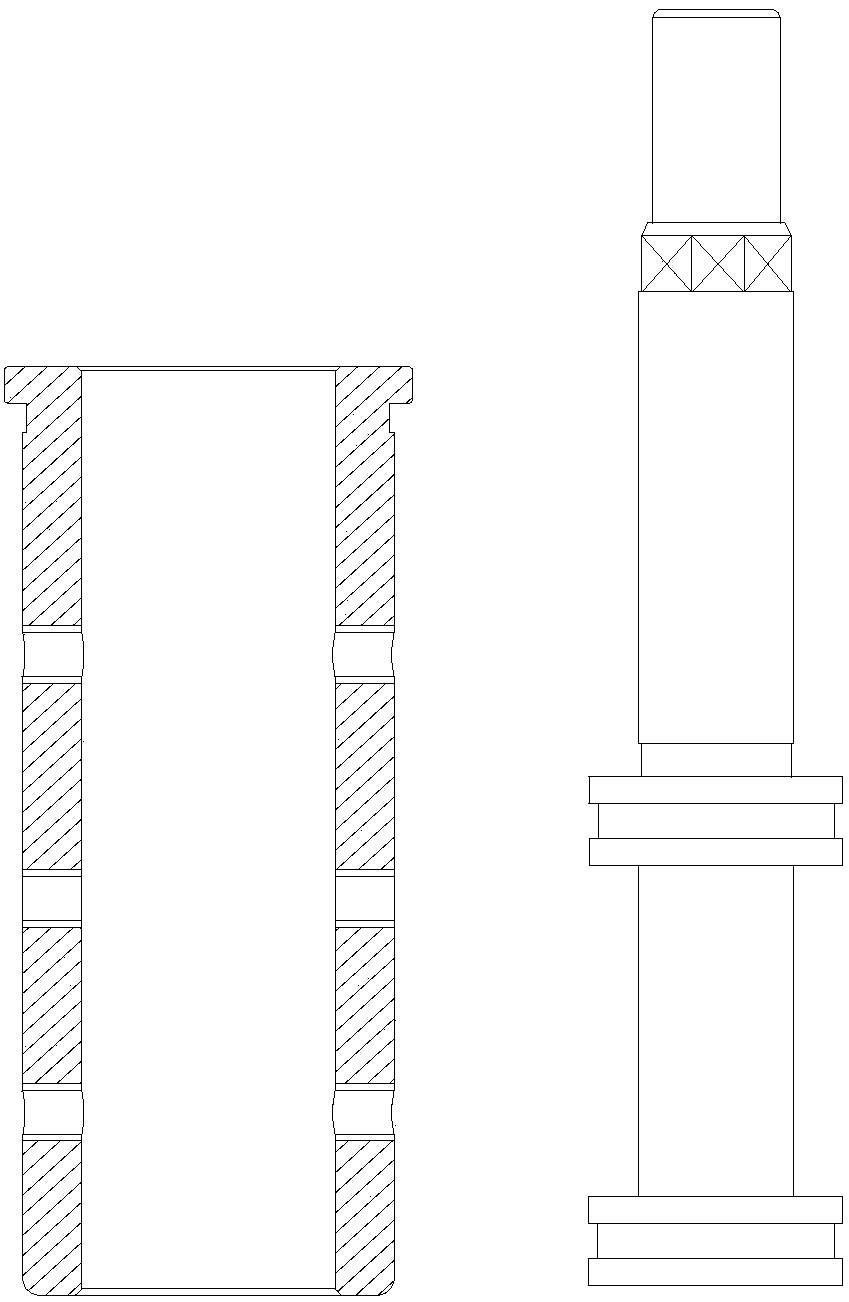

[0031] Example 1 Matching Grinding and Finishing Technology of High Oil Pressure Main Matching Bushing and Main Matching Piston

[0032] Such as figure 1 The schematic diagram of the structure of the high oil pressure main matching bushing and the matching main matching piston shown in , first install the high oil pressure main matching bushing on the inner circle lapping machine, Roughly grind the circle, and measure the bushing after 5 seconds of rough grinding. When the measured margin for fine grinding after rough grinding is 20 microns, smooth grind the inner circle of the bush after rough grinding. The inner circle of the bush is finely trimmed and finely ground by the grinding wheel. After fine grinding, it is polished for 2 seconds. When the inner circle accuracy of the bush is measured to reach the IT7 level, the preliminary fine grinding process of the inner circle of the bush is completed. After the fine grinding, the high oil pressure main The surface roughness of...

Embodiment 2

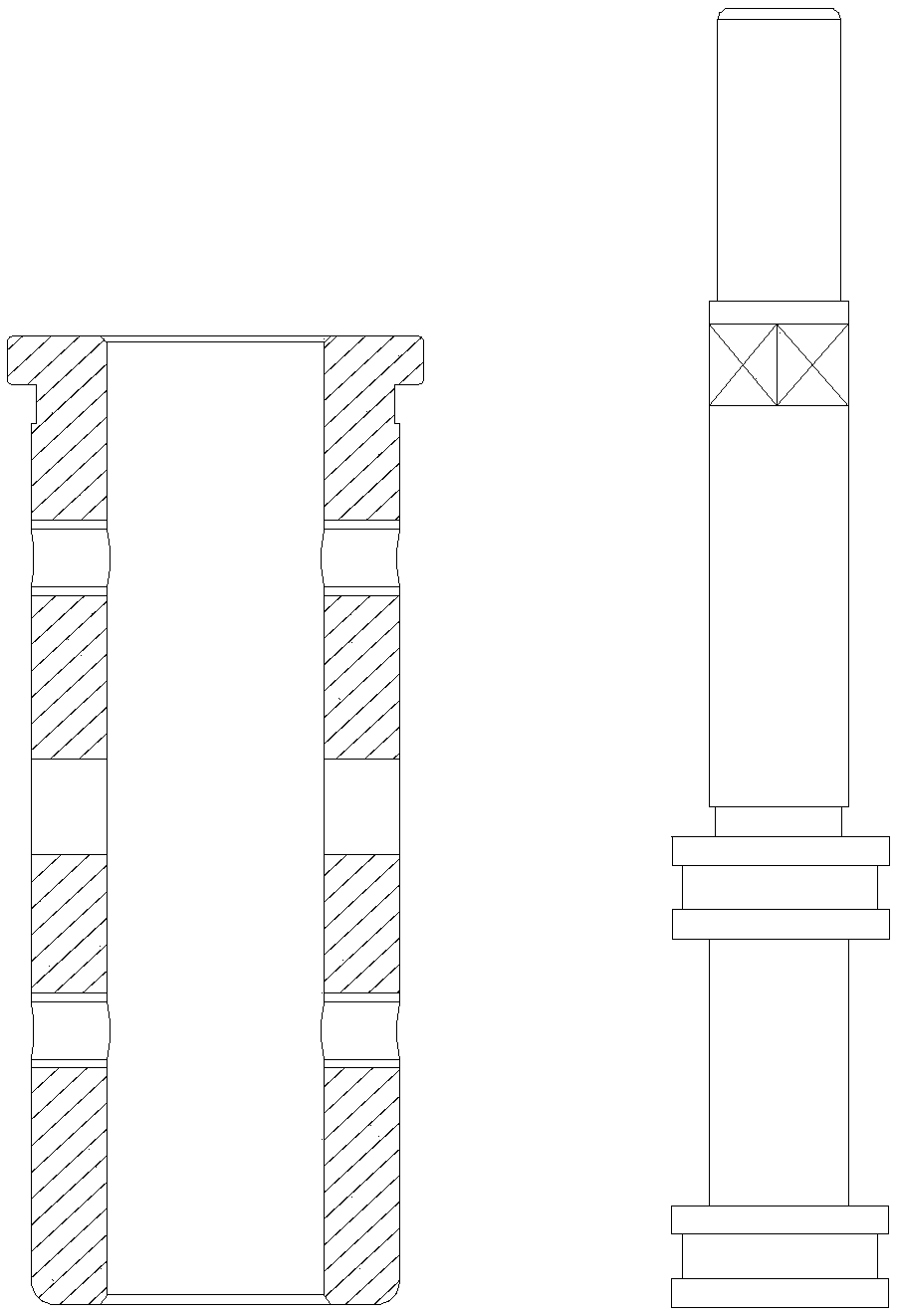

[0033] Example 2 Matching grinding and finishing process of high oil pressure punching main matching bushing and main matching piston

[0034] Such as figure 2The structural diagram of the high oil pressure punching main matching bush and the matching main matching piston shown in , firstly install the high oil pressure punching main matching bush The inner circle of the main matching bush is roughly ground, and the bush is measured after rough grinding for 5 seconds. Grinding, after smooth grinding, carry out fine dressing and fine grinding on the inner circle of the bushing, and smooth grinding for 2 seconds after the fine grinding. After grinding, the inner surface roughness of the high oil pressure punched main matching bush is 0.5, and the inner diameter is 23.013mm. According to the measured size of the high oil pressure main matching bush, the main matching piston is matched and ground. After rough grinding, the piston has a grinding amount of 150 microns and then en...

Embodiment 3

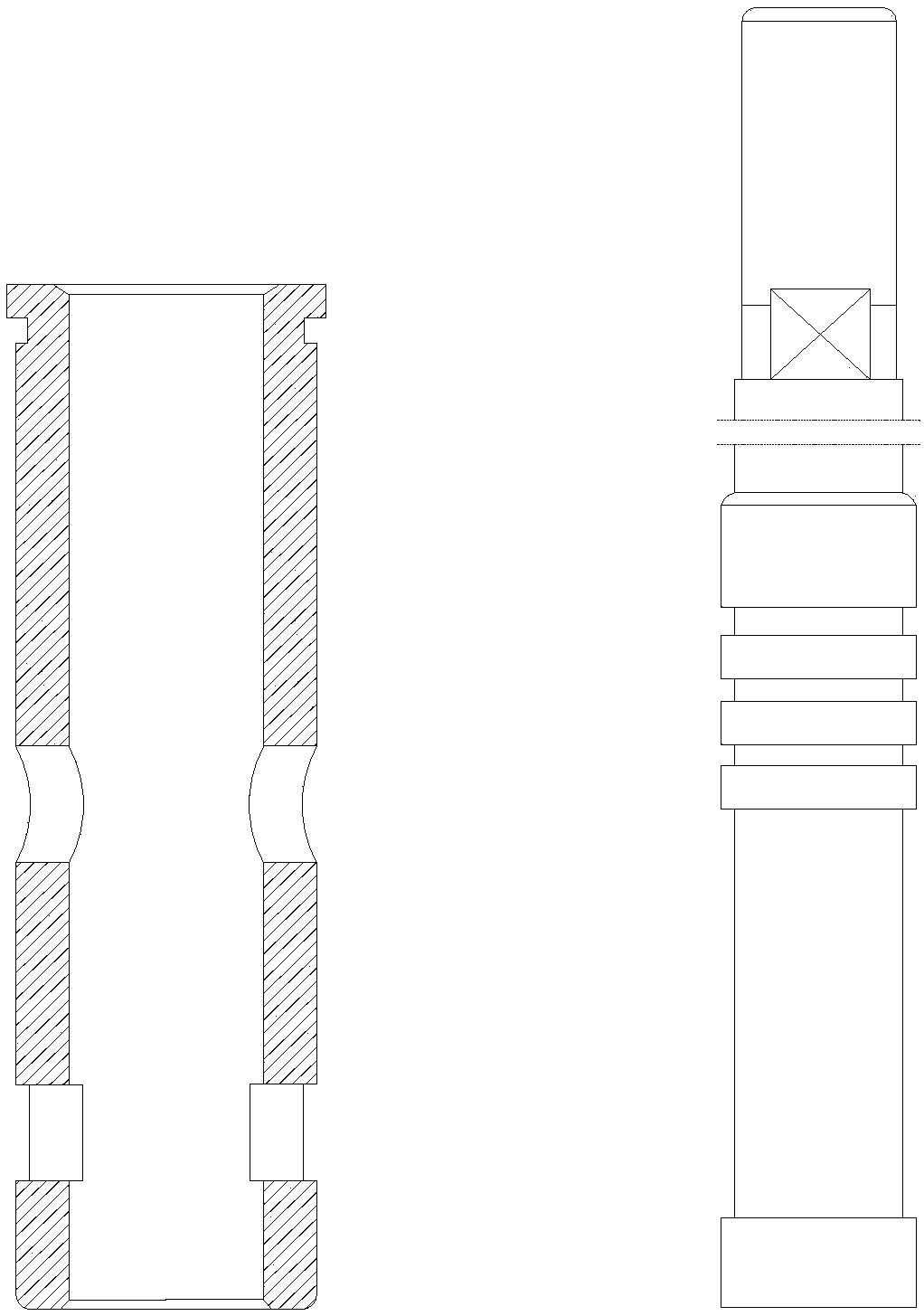

[0035] Example 3 Matching Grinding and Finishing Technology of Auxiliary Valve Bushing and Needle Plug

[0036] Such as image 3 The schematic diagram of the auxiliary valve bushing and the matching needle plug shown in , first install the auxiliary valve bushing on the inner circle lapping machine, and rough grind the inner circle of the auxiliary valve, and then grind the bushing after 5 seconds Carry out the measurement, when it is measured that the margin left for fine grinding after rough grinding is 20 microns, carry out smooth grinding on the inner circle of the bush after rough grinding, and carry out fine dressing and fine grinding on the inner circle of the bush after smooth grinding, After fine grinding, smooth grinding for 2 seconds, when the measured inner circle accuracy of the bush reaches IT7 level, the preliminary fine grinding process of the inner circle of the bush is completed. After fine grinding, the surface roughness of the inner circle of the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com