A fully automatic liquid-liquid multi-chamber bag making and filling machine

A multi-chamber bag, fully automatic technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems that product quality cannot be effectively guaranteed, bag space cannot be maximized, and bag design is unreasonable. Achieve the effect of low cost, improved product quality and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

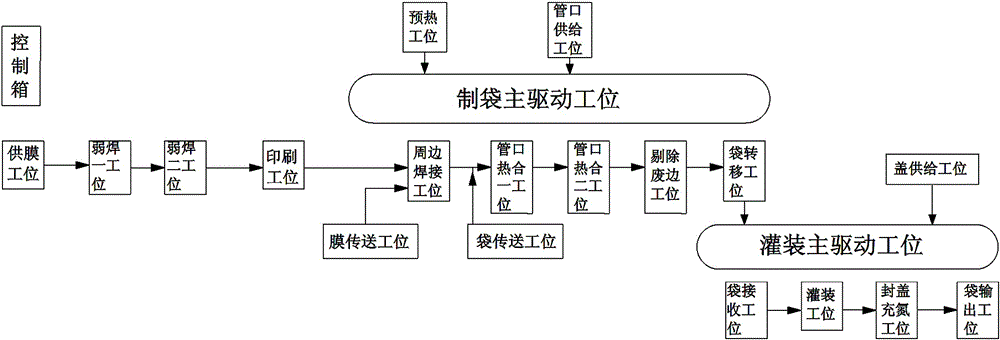

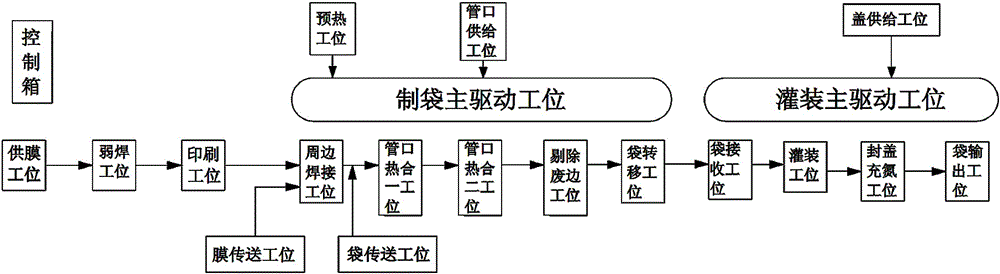

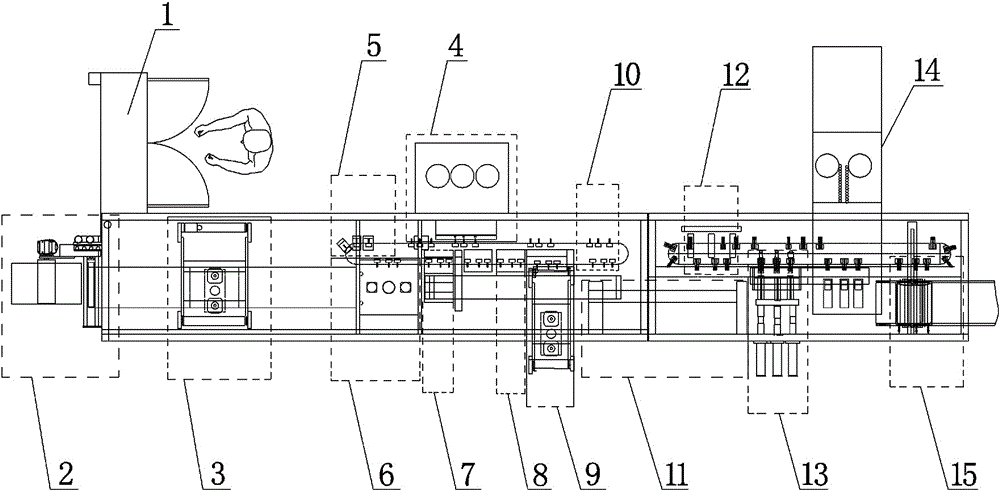

[0030] Such as image 3 and Figure 4 As shown, a fully automatic liquid-liquid multi-chamber bag making and filling machine includes a control part 1 and an execution part, the execution part is composed of a bag making part and a filling part, and the bag making part includes a film supply station 2. Bag body printing station 3. Nozzle supply station 4. Nozzle pre-welding station 5. Bag contour welding station 6. Nozzle welding station 7. Bag body shaping waste edge removal station 8. Weak welding station 9, bag body transfer station 10 and bag body transfer station 2 11, the filling part includes bag body receiving station 12, filling station 13, stoppering and nitrogen filling station 14, bag body body output station 15, one side of the executive mechanism is provided with a control part 1, a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com