Scroll compressor with ring pin structure

A technology for scroll compressors and casings, applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems affecting the industrialization process, the lack of structural parameters of scroll compressors, etc., and achieve weight Lightweight, improve fit accuracy and parameter optimization, and reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

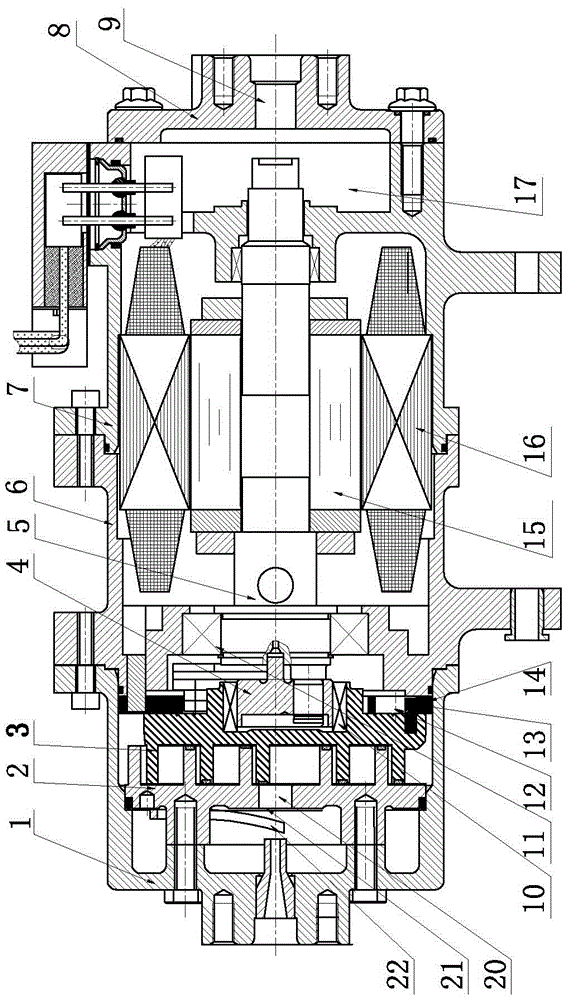

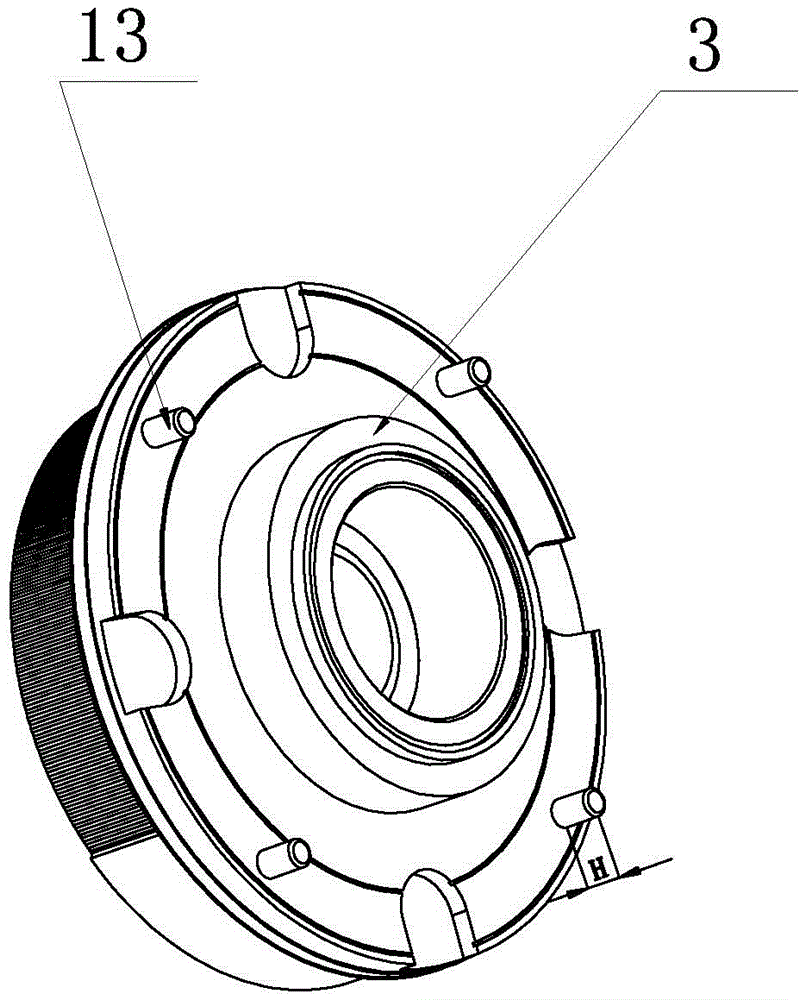

[0028] Such as Figure 1-6 shown.

[0029] An electric scroll compressor with ring pin structure, comprising a casing 1, a static disk 2, a moving disk 3, an eccentric sleeve 4, a crankshaft 5, a front cover 6, a motor casing 7 and a rear cover 8, such as figure 1 , 6 As shown, one end of the casing 1 is the exhaust end, and its other end is connected with one end of the front cover 6, and the other end of the front cover 6 is connected with one end of the motor casing 7, and the other end of the motor casing 7 is connected with the rear cover 8 are connected, the rear cover 8 is provided with an air inlet 9, and a motor installation cavity 17 communicating with the air inlet 9 is formed between the front cover 6 and the motor housing 7, and the moving plate 3 and the static plate 2 are inter-inserted and installed in the In the casing 1, one end of the eccentric sleeve 4 is installed on the moving plate 3 through the first bearing 10, and the other end of the eccentric slee...

Embodiment 2

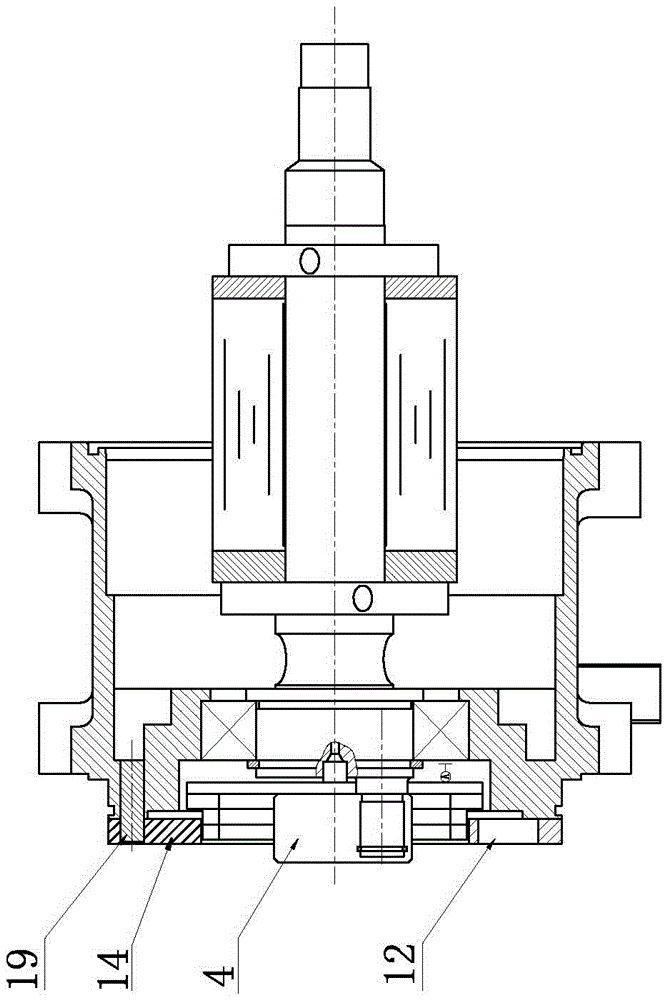

[0033] Such as Figure 7 , 8 shown.

[0034] A scroll compressor with a ring pin structure, including a casing 1, a static disk 2, a moving disk 3, an eccentric sleeve 4, a crankshaft 5, a front cover 6, a motor casing 7 and a rear cover 8, such as Figure 7 , 8 As shown, one end of the casing 1 is the exhaust end, and its other end is connected to one end of the front cover 6, and the other end of the front cover 6 is installed with a driving component, and the moving disk 3 and the static disk 2 are inserted and installed in the casing. 1, one end of the eccentric sleeve 4 is installed on the moving disk 3 through the first bearing 10, the other end of the eccentric sleeve 4 is connected with the crankshaft 5 passing through the front cover 6, and the end of the crankshaft 5 installed with the eccentric sleeve 4 is supported on the second bearing 11, its other end is also supported on the corresponding bearing and a pulley 23 is installed, and four pins 13 (such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com