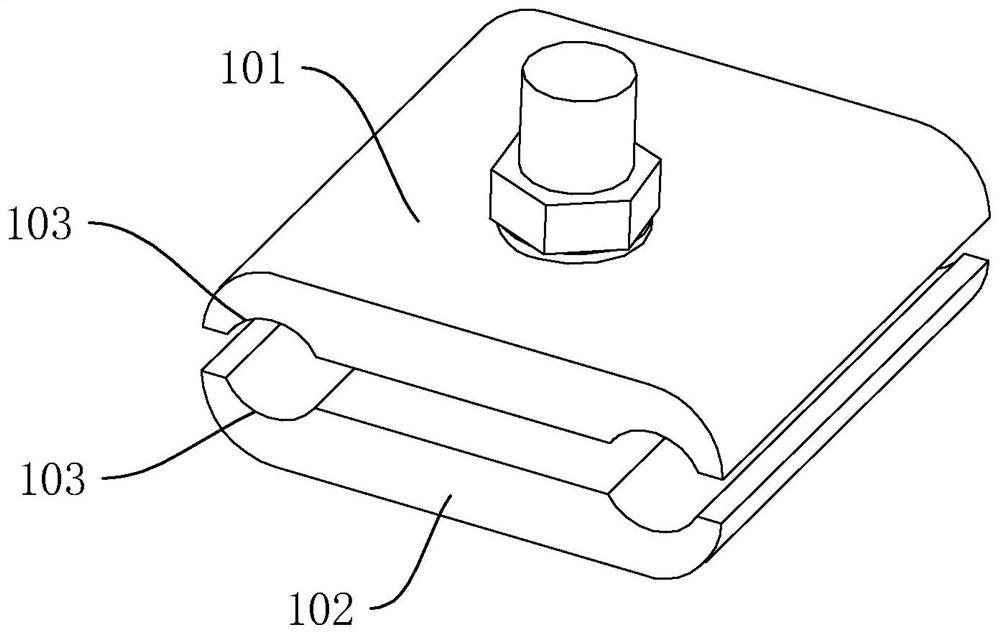

Parallel groove clamp processing device with high matching degree

A technology of processing equipment and matching degree, which is applied to other manufacturing equipment/tools, manufacturing tools, clamping/spring connections, etc., can solve problems such as low matching accuracy, easy deviation, and misalignment of arc-shaped grooves 103, so as to improve production Efficiency, good fit, and good fit precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

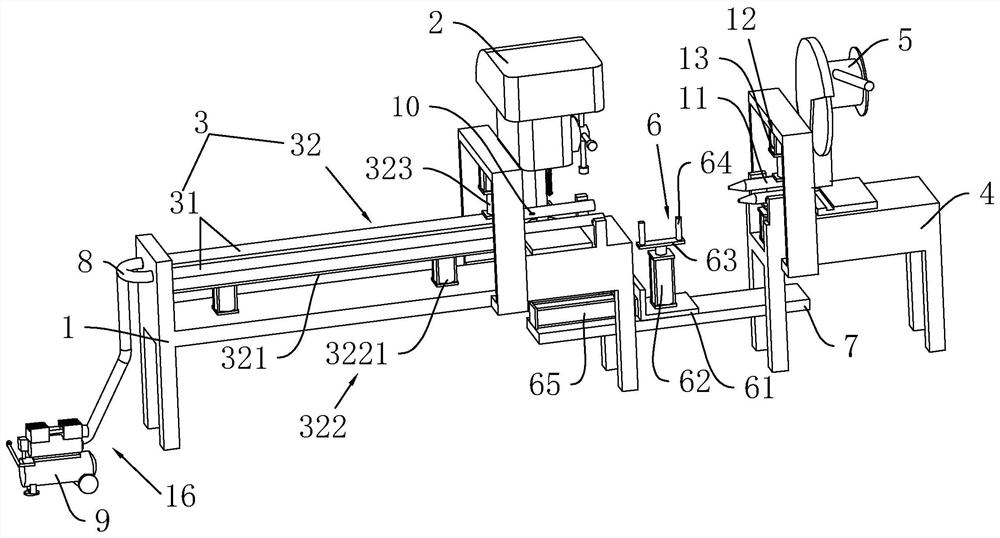

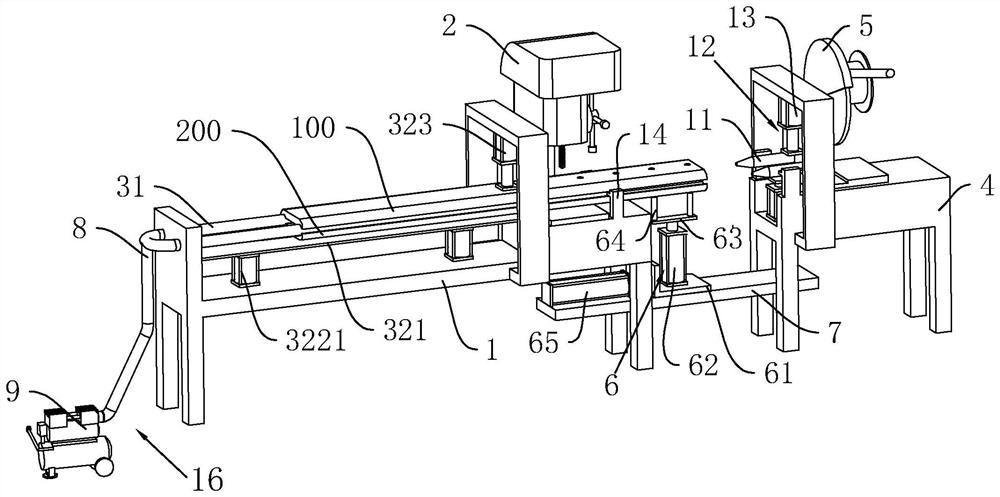

[0035] refer to figure 2 and image 3 , is a high-coordination parallel groove wire clamp processing equipment disclosed in the present invention, which is used for punching and cutting the upper strip 100 and the lower strip 200, including the workbench 1 and the punching machine installed on the workbench 1. Hole machine 2, puncher 2 can select devices such as bench drill for use. A positioning mechanism 3 for clamping the upper strip material 100 and the lower strip material 200 is installed on the workbench 1, so that the upper strip material 100 and the lower strip material 200 are in a coordinated state, and then punched by the punching machine 2, so that The precision of the drilled holes is more accurate, reducing the situation of later repairing holes. One end of the workbench 1 is also equipped with a cutting table 4, on which a cutting machine 5 for cutting the upper strip 100 and the lower strip 200 is installed. A pushing assembly 6 for delivering the upper st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com