A method and a system for automatically cutting off laminated silk-screen printing

An automatic cutting and silk-screening technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low accuracy and low PCB design efficiency, and achieve the goal of improving efficiency, cutting efficiency and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

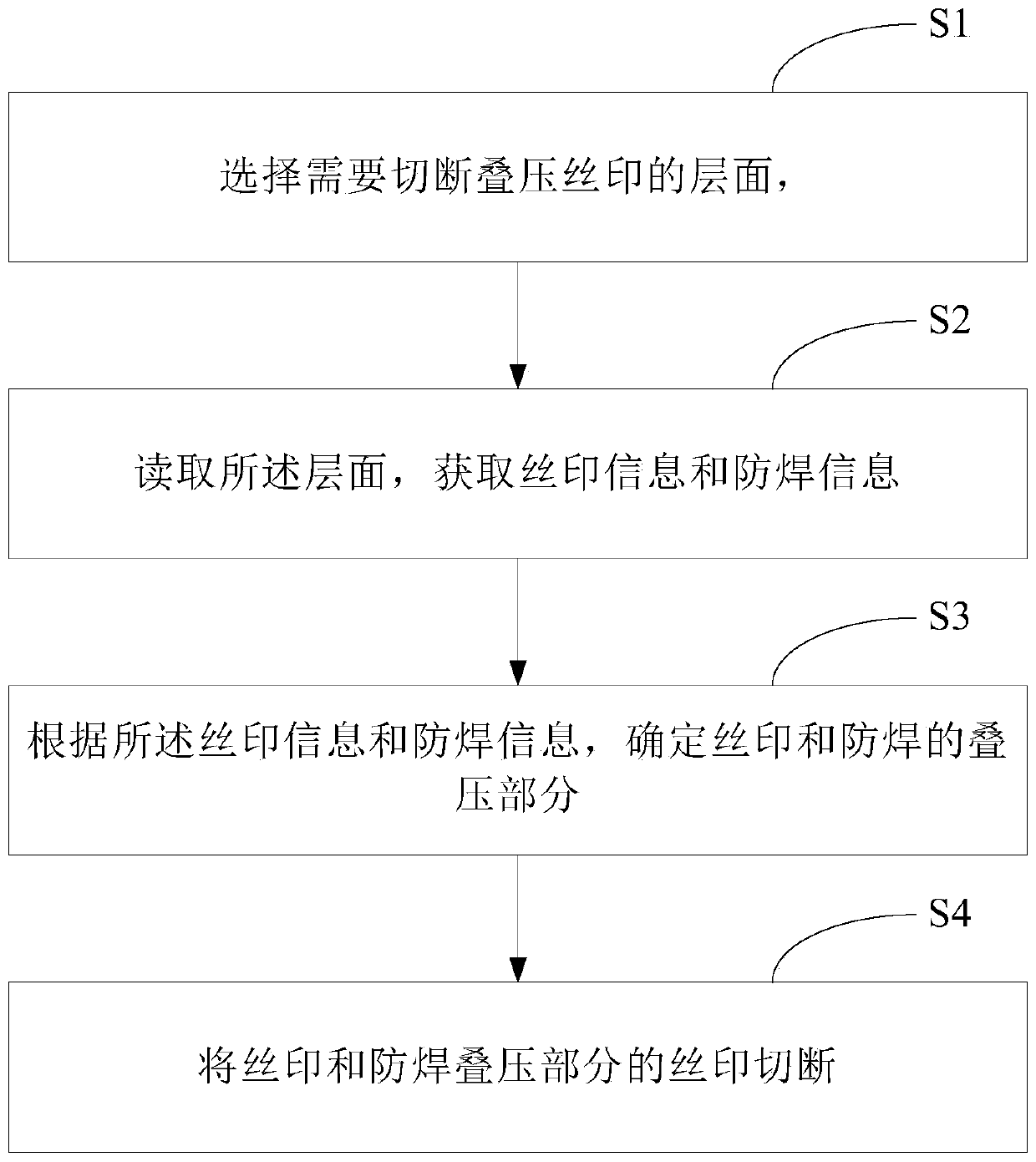

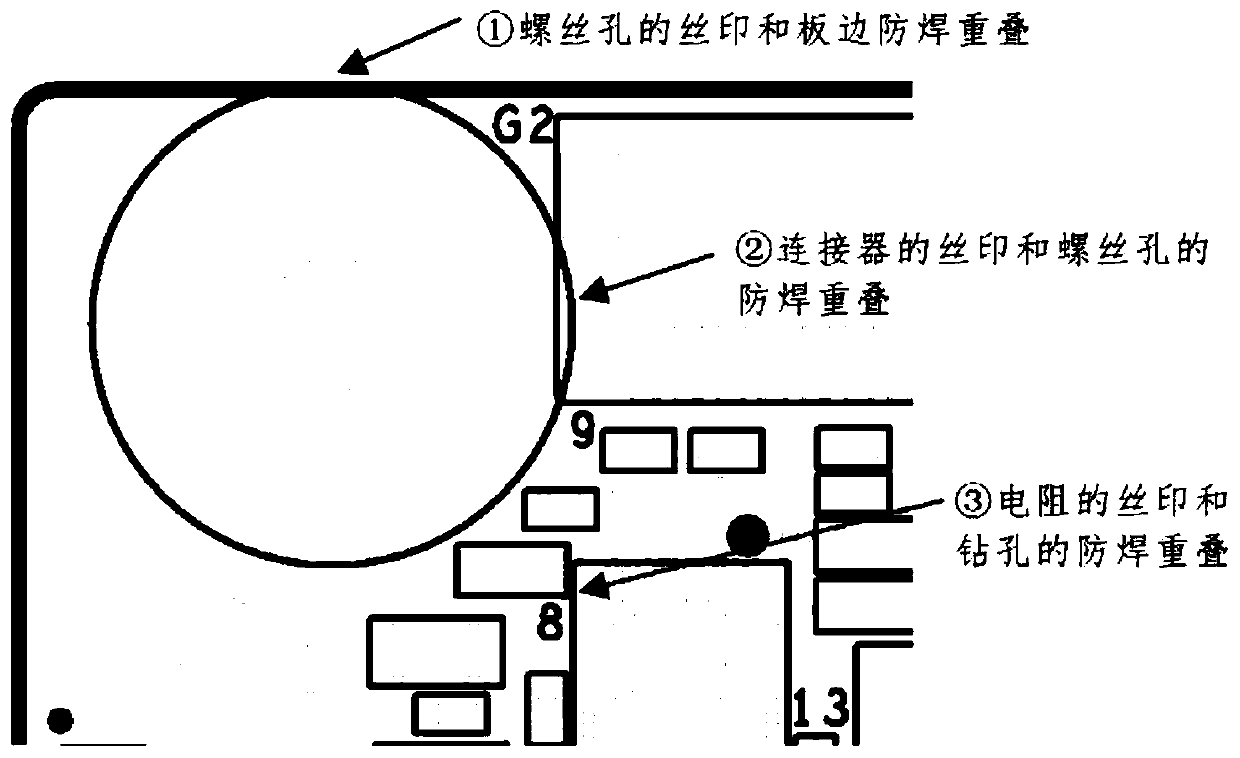

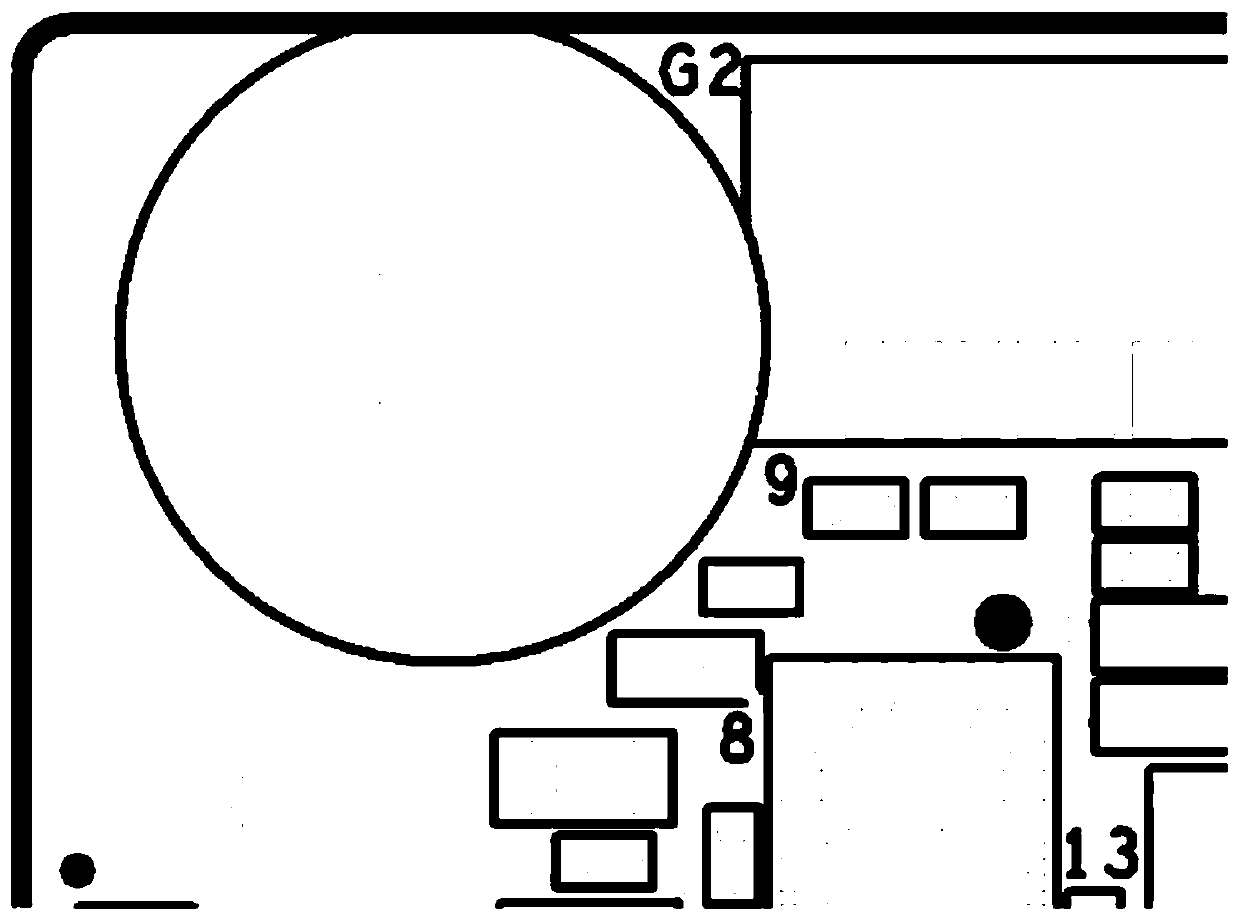

[0043] see figure 1 , figure 1 It is a schematic flow chart of a method for automatically cutting the laminated silk screen provided by the embodiment of the present application. Depend on figure 1 It can be seen that the method for automatically cutting off the laminated silk screen in this embodiment mainly includes the following process:

[0044] S1: Select the layer that needs to cut off the superimposed silk screen. Wherein, the layers in this embodiment include at least one layer of the Top silkscreen layer, the Bottom silkscreen layer, the Top solder mask layer and the Bottom solder mask layer. That is: one or more layers of Top silk screen layer, Bottom silk screen layer, Top solder mask layer and Bottom solder mask layer.

[0045] The PCB usually includes multiple layers. In this embodiment, only the silk screen layer and / or the solder mask layer related to the laminated silk screen can be selected according to the acquired command. Among them, the Top silkscreen...

Embodiment 2

[0065] exist Figure 1-Figure 3 On the basis of the illustrated embodiment see Figure 4 , Figure 4 It is a schematic structural diagram of a system for automatically cutting laminated silk screens provided in the embodiment of the present application. Depend on Figure 4 It can be seen that the system for automatically cutting the laminated silk screen in this embodiment mainly includes: a layer selection module, a silk screen information and solder mask information acquisition module, a laminated part determination module and a cutting module.

[0066] Wherein, the layer selection module is used to select the layer that needs to cut off the laminated silk screen, wherein the layer in this embodiment includes at least one layer of the Top silk screen layer, the Bottom silk screen layer, the Top solder mask layer and the Bottom solder mask layer. The silk screen information and solder mask information acquisition module is used to read the selected layer and obtain the sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com