Ultraviolet light-responsive polymer adhesive and its preparation method and use

An ultraviolet light, responsive technology, applied in the preparation of organic compounds, adhesives, chemical instruments and methods, etc., can solve the problem of difficult to achieve high-efficiency and high-quality regioselective transfer, and achieve regioselective transfer. The effect of printing, easy availability of raw materials and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the above UV-responsive polymer adhesive is simple and has sensitive viscosity adjustability. And, in the present invention, the raw material that is used to prepare polymer binder all can be purchased commercially, and for example raw material n-suberic acid can be purchased from Ti Xiai (TCI) company (commodity O0023), and other raw materials such as 2- Nitro-m-xylylenedimethanol, 2,5-dimethylnitrobenzene, and other starting materials used in their redox reactions are all commercially available chemical reagents commonly used in the art.

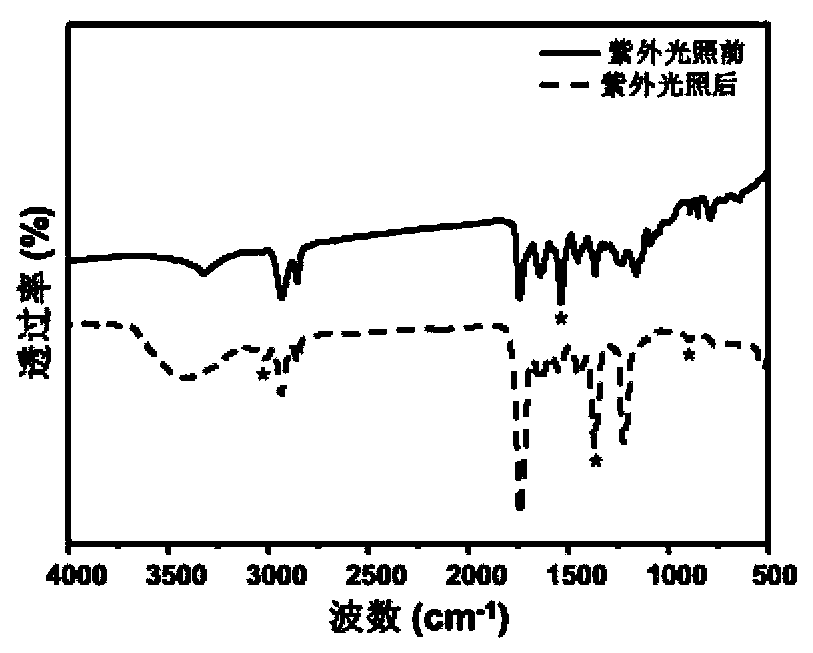

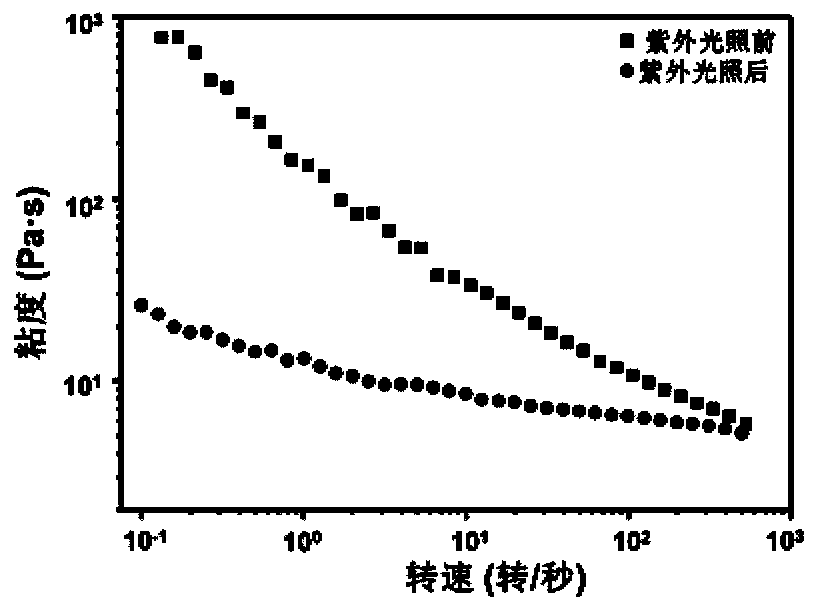

[0054] The polymer adhesive of the present invention can be used to improve the adhesion of the stamp or the stamp substrate, and when the stamp extracts the target functional device to be transferred from the parent substrate, it can provide high viscosity and realize 100% extraction of the functional device . After extraction, after being pasted to the target flexible substrate, the polymer adhesive unde...

Embodiment

[0061] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail through the following examples. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0062] Unless otherwise defined, all technical terms and scientific terms used herein have the same meaning as commonly understood by those skilled in the technical field of the present invention, and the terms used in the description of the present invention herein are only to describe specific implementations The purpose of the example is not intended to limit the present invention.

[0063] All starting materials and reagents used in the following examples were obtained commercially and used without further treatment unless otherwise stated.

Synthetic example 1

[0066] In a 500 mL reactor, 8.2 g of 2-nitro-m-xylylenedimethanol (commercially obtained), 7.8 g of n-suberic acid, 360 mg of 4-dimethylaminopyridine, and 21 g of dicyclohexylcarbodiimide Dissolve in 75 mL of dry DMF. After vacuumizing the reactor three times and replacing the nitrogen atmosphere, the polycondensation reaction was carried out by heating to 80° C. in an oil bath for 72 hours in a nitrogen atmosphere. After the reaction was completed, the reaction mixture was cooled to room temperature and diluted with 50 mL of anhydrous DMF, followed by gravity filtration. The obtained filtrate was concentrated to 5 mL, and then precipitated in 200 mL of anhydrous ether, and the precipitate (ie polymer) was collected and dried at room temperature for 12 hours to obtain the desired UV-responsive polymer binder.

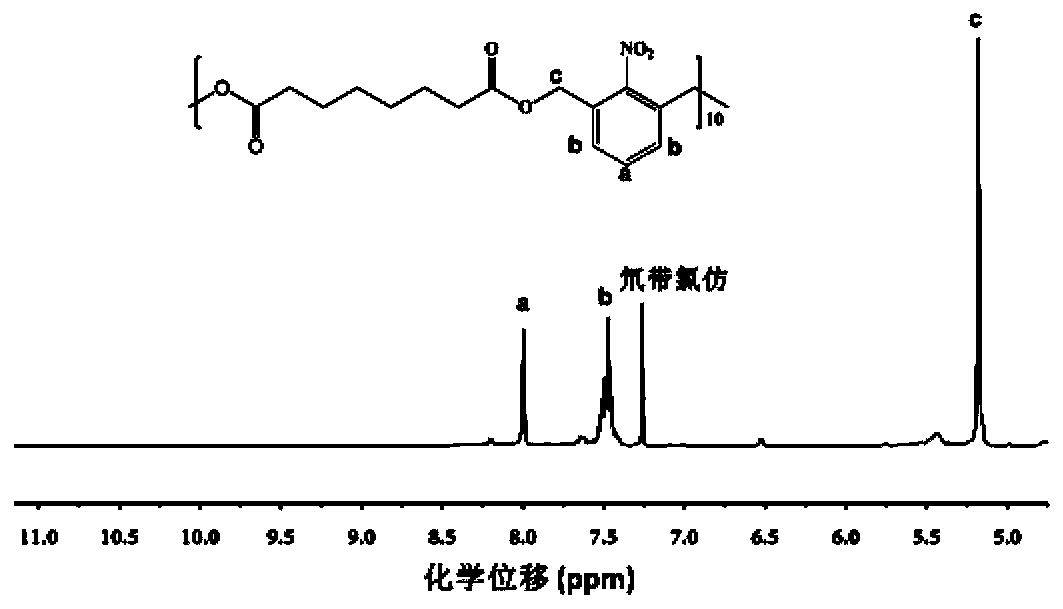

[0067] The molecular weight of the obtained polymer was measured by gel permeation chromatography GPC (gel permeation chromatography model: Waters 1515, manufacturer: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com