High-heat-resistance packaging adhesive, LED packaged device employing same and packaging method

A technology of LED packaging and high heat resistance, which is applied in the direction of semiconductor devices, electrical components, non-polymer adhesive additives, etc., can solve the problems of limited lifting range, discoloration, low ratio, etc., and achieves mild conditions, high yield rate, The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a high heat-resistant encapsulant. In parts by weight, the encapsulant is composed of 100 parts of colloidal material and 5 parts of fluoride material, wherein the colloidal material is a single-component silica gel, and its refractive index is is 1.4, the fluoride material is lutetium fluoride, and its average particle size is 10nm-50 μm, preferably 50nm-30 μm in this embodiment, and the colloid material and the fluoride material are mixed evenly with a mixer to obtain a high Heat-resistant encapsulant.

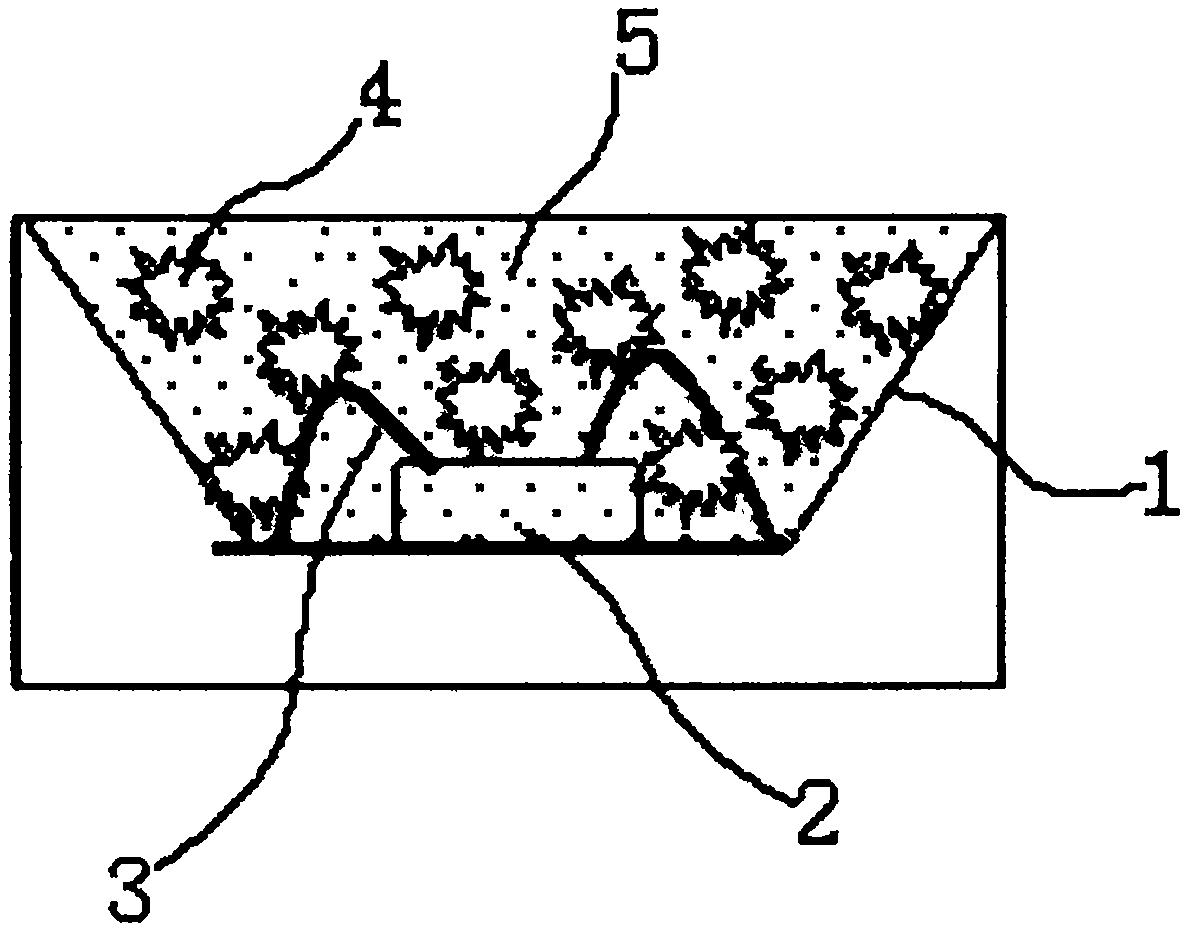

[0030] This embodiment also provides an LED packaging device using the above-mentioned high heat-resistant packaging glue, the LED packaging device such as figure 1 As shown, it includes an LED bracket 1, and at least one LED chip 2 is mounted on the LED bracket 1. In this embodiment, the LED bracket 1 is a 2835 bracket, and the LED chip 2 is a blue LED chip. The LED chip 2 is electrically connected to the positive and negative electrodes of ...

Embodiment 2

[0037] This embodiment provides a high heat-resistant encapsulant. In parts by weight, the encapsulant is composed of 100 parts of colloidal material and 500 parts of fluoride material, wherein the colloidal material is a two-component epoxy resin, which The refractive index is 1.55, the fluoride material is zirconium tetrafluoride, and its average particle size is 10nm-50μm, preferably 500-1000nm in this embodiment, and the colloid material and the fluoride material are mixed evenly with a mixer That is, a highly heat-resistant encapsulant is obtained.

[0038] This embodiment also provides an LED packaging device using the above-mentioned high heat-resistant packaging glue. The structure of the LED packaging device is basically the same as that of Embodiment 1, the difference is that the LED support 1 is a filament support, and the number of LED chips 2 is 28. Blue light LEDs are mounted with chips, and the LED chips 2 and between the LED chips 2 and the LED bracket 1 are co...

Embodiment 3

[0041] This embodiment provides a high heat-resistant encapsulant. In parts by weight, the encapsulant is composed of 100 parts of colloidal material and 400 parts of fluoride material, wherein the colloidal material is a two-component silica gel, and its refractive index is is 1.44, the fluoride material is magnesium fluoride, and its average particle size is 10nm-50 μm, preferably 5-30 μm in this embodiment, and the colloid material and the fluoride material are mixed evenly with a mixer to obtain a high Heat-resistant encapsulant.

[0042] This embodiment also provides an LED packaging device using the above-mentioned high heat-resistant packaging glue. The structure of the LED packaging device is basically the same as that of Embodiment 1, the difference is that the LED support 1 is a filament support, and the number of LED chips 2 is 28. Blue light LEDs are mounted with chips, and the LED chips 2 and between the LED chips 2 and the LED bracket 1 are connected by gold wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com