Rubber-blended macromolecular compatibilizer, preparation method and application thereof

A technology of macromolecules and compatibilizers, applied in the field of rubber combined with macromolecular compatibilizers, can solve the problems of poor physical and mechanical properties, thermodynamic incompatibility, and poor compatibility of vulcanizates, and achieve good compatibilization effect, The effect of many activation fulcrums, simple and pollution-free synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

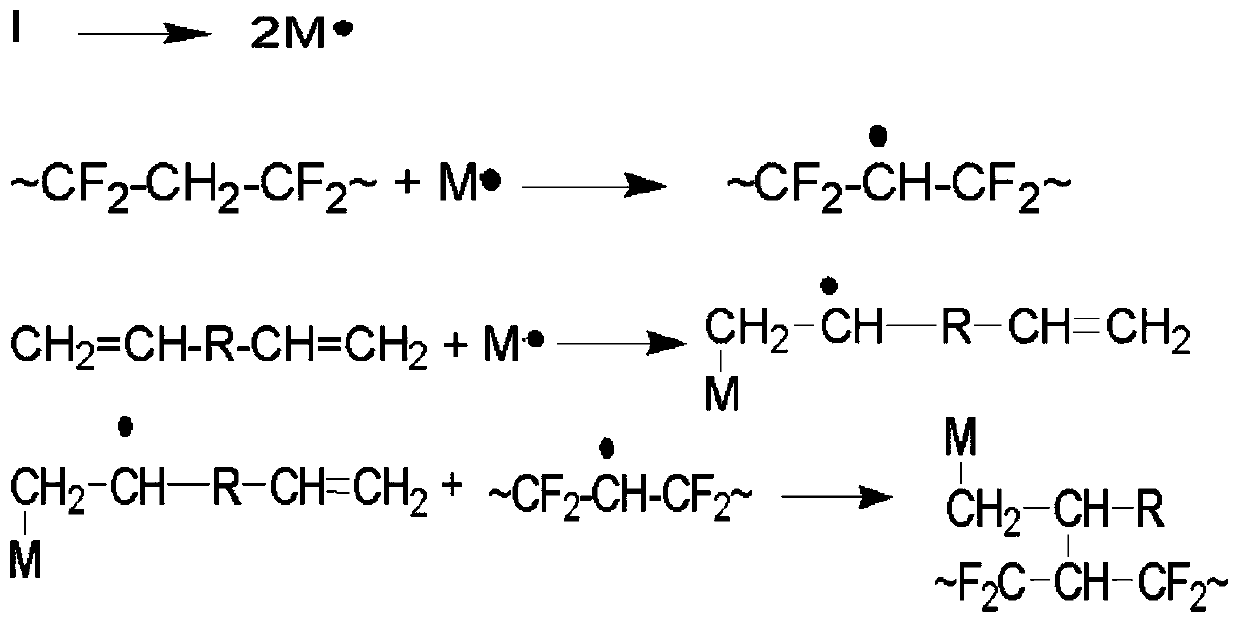

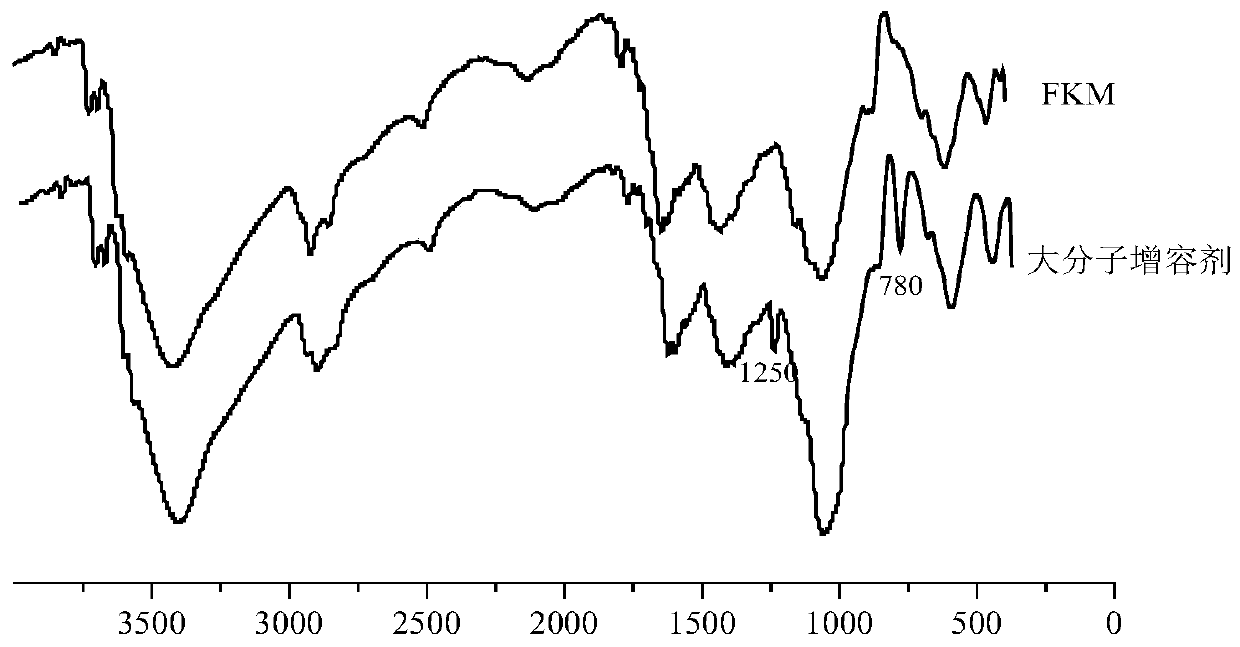

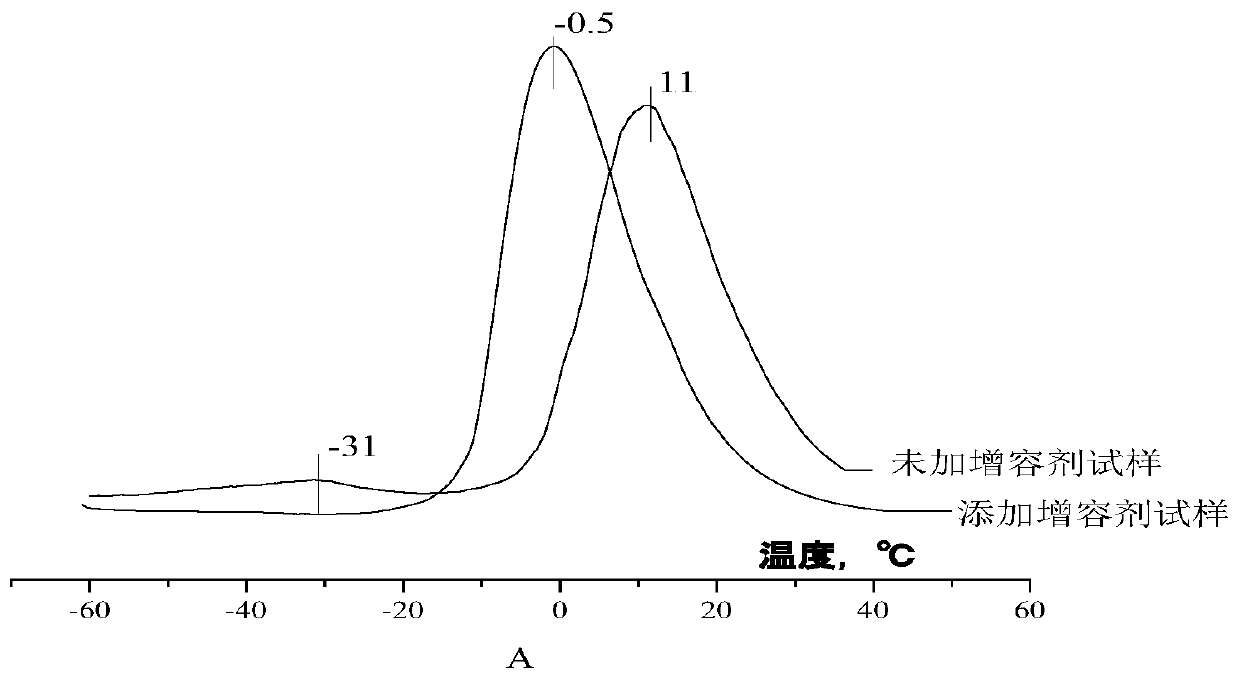

Method used

Image

Examples

Embodiment 1

[0031] The raw materials in this embodiment are: 100 parts by mass of FKM raw rubber, 100 parts by mass of MVQ raw rubber, and the vulcanized small material of FKM rubber includes MgO3%, Ca(OH) 2 6%, stearic acid 1%, MVQ rubber vulcanization small material includes fumed white carbon black 20%, dicumyl peroxide (DCP) 6%, auxiliary vulcanization agent TAIC 3%.

[0032] This example is to vulcanize FKM and MVQ without adding compatibilizer and blend rubber. The specific implementation steps are as follows:

[0033] (1) Add FKM raw rubber to the open mill, adjust the roller distance to 2mm, add fluorine rubber vulcanization small materials after wrapping the rolls, make triangular bags 3 times on the left and right sides after thinning, and release the pieces after the materials are evenly eaten to obtain fluorine rubber master Rubber mixing a.

[0034] (2) Add MVQ raw rubber to the open mill, adjust the roll distance to 2mm, add silicone rubber vulcanized small materials after ...

Embodiment 2

[0039] The raw material composition of the macromolecule compatibilizer in this embodiment is: 100 parts by mass of FKM raw rubber, 5 parts by mass of grafting agent A500CS terminal vinyl silicone oil, 0.5 parts by mass of lubricant B stearic acid, initiator C diperoxide 0.5 parts by mass of cumene.

[0040]The preparation method of rubber and macromolecule compatibilizer is as follows in the present embodiment:

[0041] 1. Add FKM raw rubber, grafting agent A, lubricant B, and initiator C into the open mill, adjust the roll distance to 2 mm, make triangular bags on the left and right sides of the thin pass three times, and discharge to obtain mixture a;

[0042] 2. Put the mixture a obtained in step 1 into the internal mixer, and then banbury at 160°C and 60 rad / min for 10 minutes, then discharge to obtain the primary product of the macromolecule compatibilizer;

[0043] 3. Cut the primary product of the macromolecule compatibilizer obtained in step 2 into pieces and put it ...

Embodiment 3

[0046] The raw material composition of the macromolecular compatibilizer in this embodiment is: 100 parts by mass of FKM raw rubber, 5 parts by mass of grafting agent A1000CS terminal vinyl silicone oil, 0.5 parts by mass of lubricant B stearic acid, initiator C diperoxide 0.5 parts by mass of cumene.

[0047] The preparation method of rubber and macromolecule compatibilizer is as follows in the present embodiment:

[0048] 1. Add FKM raw rubber, grafting agent A, lubricant B, and initiator C into the open mill, adjust the roll distance to 2 mm, make triangular bags on the left and right sides of the thin pass three times, and discharge to obtain mixture a;

[0049] 2. Put the mixture a obtained in step 1 into the internal mixer, and then banbury at 160°C and 60 rad / min for 10 minutes, then discharge to obtain the primary product of the macromolecule compatibilizer;

[0050] 3. Cut the primary product of the macromolecule compatibilizer obtained in step 2 into pieces and put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com