Contaminated soil remediation method

A technology of polluted soil and remediation method, applied in the field of remediation of chemical plant sites, can solve the problems of difficult to normal soil, increase of soil heavy Cd, soil erosion, etc., and achieve the effect of avoiding air pollution and making full use of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

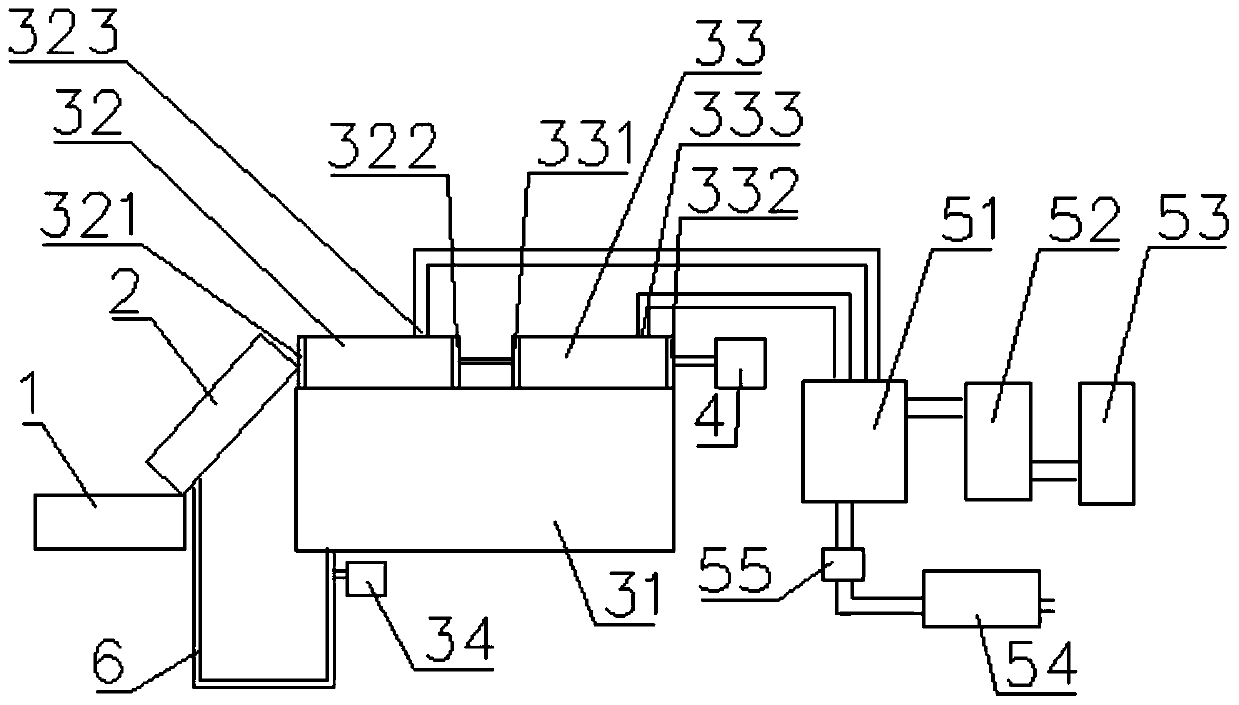

[0081] Please refer to Figure 1~Figure 5 And table 1, a kind of polluted soil remediation method, comprises the steps:

[0082] Step 1, mixing the polluted soil and quicklime together to make the polluted soil change from massive to granular, and then sieve out the impurities in the mixture of polluted soil and quicklime by a drum screening machine;

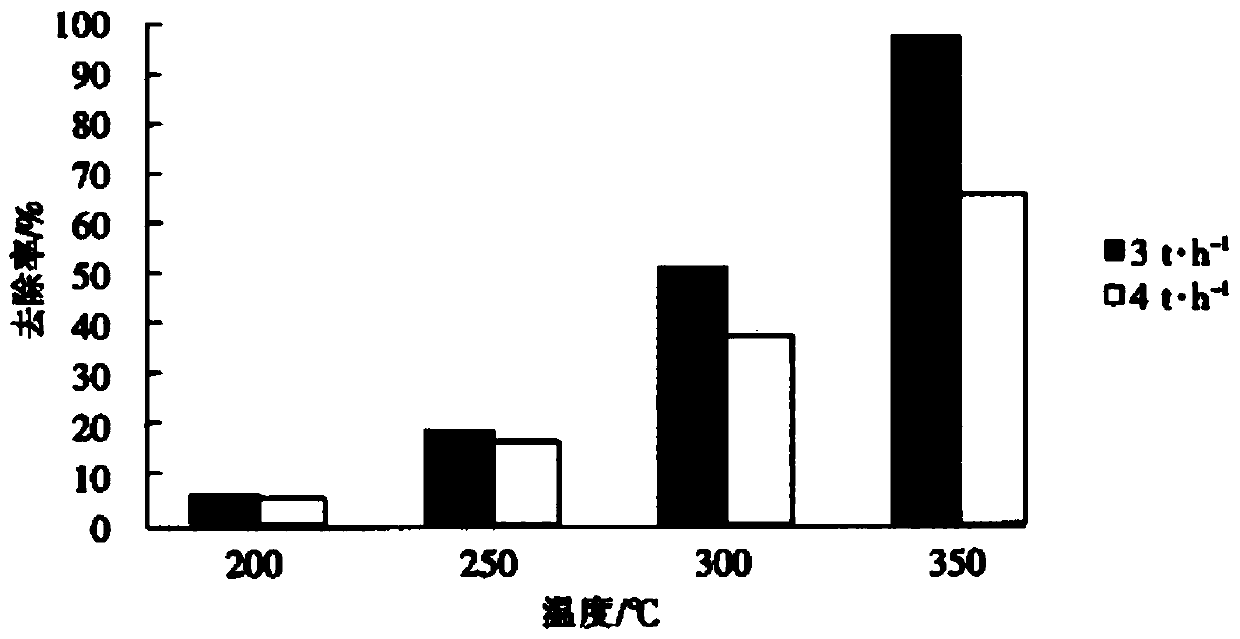

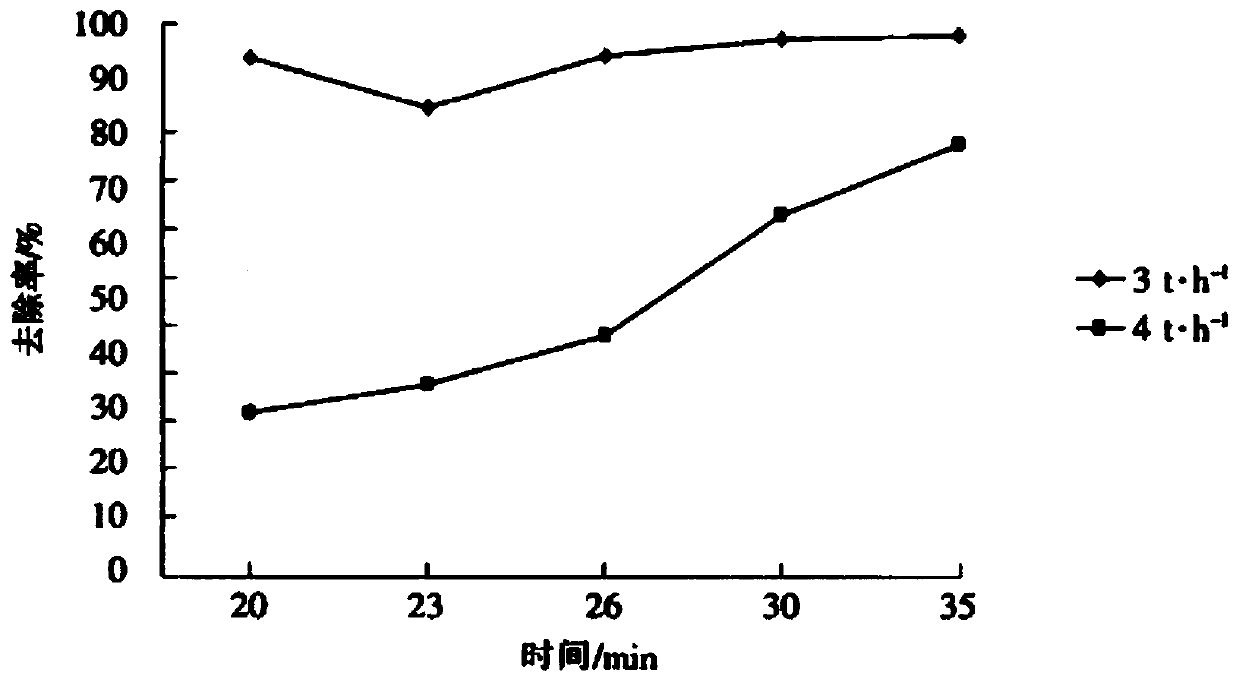

[0083] Step 2, preheating the contaminated soil treated in step 1 with the flue gas produced by the fuel combustion of the thermal desorption device, and then putting it into the thermal desorption device for secondary heating;

[0084] Step 3, the mixed steam generated after the second heating in step 2 is sprayed with cooling water, defogged and activated carbon in sequence, and discharged into the atmosphere at high altitude; the soil heated in step 2 is directly discharged;

[0085] Step 4, spray water mist to the soil discharged in step 3, and perform humidification and dust removal;

[0086] Step 5, transporting the soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com