Method for in-situ circularly promoting catalytic performance of NiP amorphous alloy

A technology of amorphous alloy and catalytic performance, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. It can solve the problems of electrolyzed water and high hydrogen evolution overpotential, and achieve surface roughness increase and hydrogen evolution The effect of performance improvement and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, comprises the following steps:

[0024] Step 1), using pure nickel (99.99%) and red phosphorus (99.999%) as raw materials, according to NiP 22 The atomic percentage is configured with a master alloy, and the master alloy is first induction-melted into an alloy ingot in a melting and quenching strip machine;

[0025] Step 2), put the alloy ingot into the vacuum arc melting furnace for further melting, so that the composition is more uniform, which is beneficial to the subsequent stripping;

[0026] In step 3), the alloy ingot melted by vacuum arc is prepared by strip throwing method to prepare amorphous thin strips, wherein, in order to suppress the process of crystal nucleation and growth of crystal nuclei, the cooling rate is controlled by 10 4 K / s~10 6 K / s;

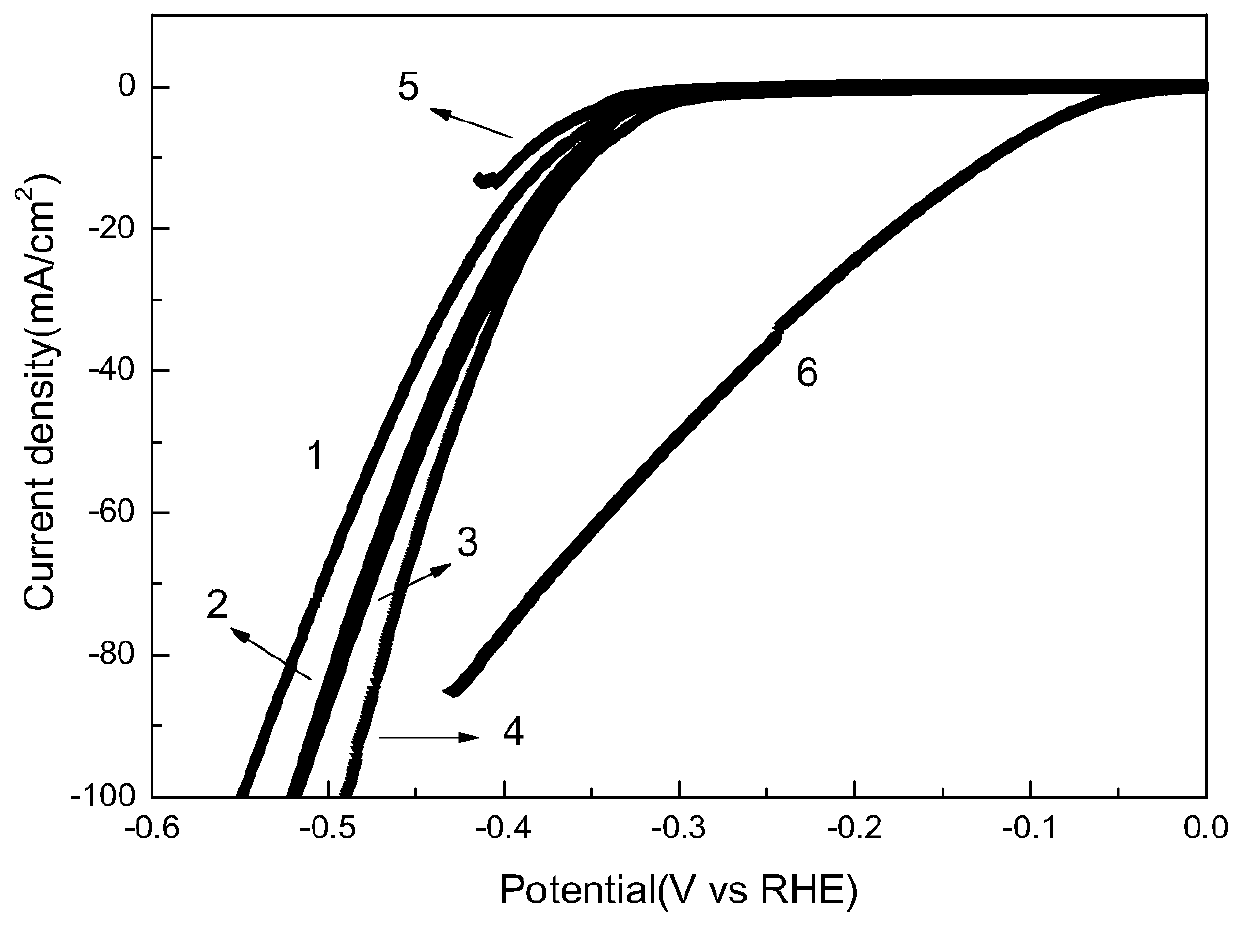

[0027] Step 4), using 1M KOH as the electrolyte, connecting the amorphous strip to a copper wire as a working electrode, a graphite electrode as a counter electrode, and a Hg / HgO / 1M KOH electrode...

Embodiment 2

[0028] Embodiment 2, comprises the steps:

[0029] Step 1)-step 3) repeat embodiment 1;

[0030] Step 4), using 1M KOH as the electrolyte, connecting the amorphous strip to a copper wire as a working electrode, a graphite electrode as a counter electrode, and a Hg / HgO / 1M KOH electrode as a reference electrode. With a scanning speed of 500mV / s, in the voltage range of -0.4V~-2V, scan the cyclic voltammetry curve 10,000 times, and then measure the polarization curve at 5mV / s.

Embodiment 3

[0031] Embodiment 3, comprises the following steps:

[0032] Step 1)-step 3) repeat embodiment 1;

[0033] Step 4), using 1M KOH as the electrolyte, connecting the amorphous strip to a copper wire as a working electrode, a graphite electrode as a counter electrode, and a Hg / HgO / 1M KOH electrode as a reference electrode. With a scanning speed of 500mV / s, in the voltage range of -0.4V~-2V, scan the cyclic voltammetry curve 20,000 times, and then measure the polarization curve at 5mV / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com