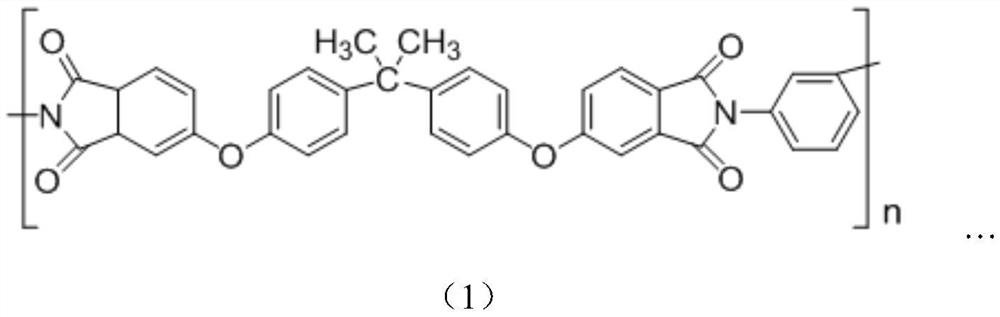

Carbon fiber for polyetherimide resin-based composite material and preparation method thereof

A polyetherimide resin and polyetherimide-based technology, which is applied in the field of carbon fiber for polyetherimide resin-based composite materials and its preparation, can solve problems such as poor impregnation, aging and hardening of fibers, and achieve preparation Simple equipment and process, excellent temperature resistance and interface bonding ability, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

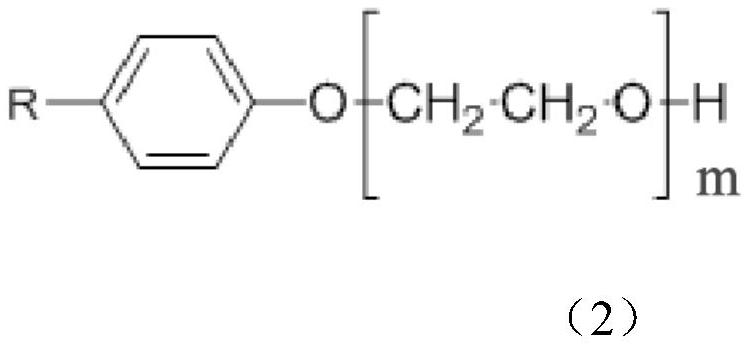

Method used

Image

Examples

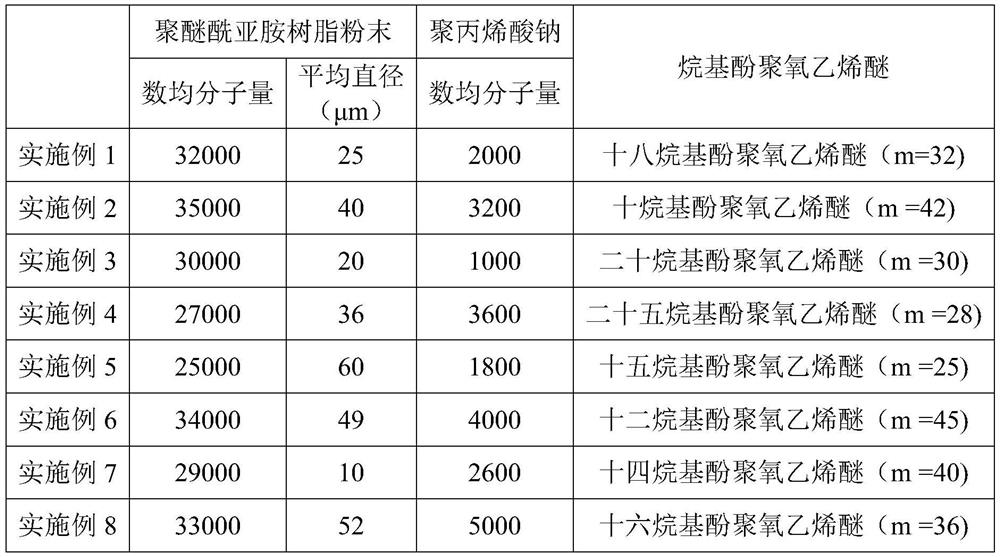

Embodiment 1~4

[0050] Examples 1 to 4 are a manufacturing method of 50K carbon fibers suitable for polyetherimide resin-based composite materials, including polymerization, spinning, pre-oxidation, low-temperature carbonization, high-temperature carbonization, surface treatment, water washing, and drying before sizing , sizing, drying after sizing, winding and winding production process. The specific process is as follows:

[0051] Step 1: Aggregation.

[0052] Adopt sodium thiocyanate aqueous solution as solvent to carry out solution polymerization, take acrylonitrile, methyl methacrylate, sodium itaconate as polymerization monomer, the weight ratio of acrylonitrile, methyl methacrylate, sodium itaconate is 91.5: 5.2:3.3, the feed concentration of total polymerized monomer is 23.5wt%, add initiator azobisisobutyronitrile simultaneously, initiator consumption is 0.52wt% with all polymerized monomer total amount, 81 ℃ of polymerization temperature, The reaction time was 92 minutes.

[0053...

Embodiment 5~8

[0070] Examples 5 to 8 are a method for manufacturing 60K carbon fibers suitable for polyetherimide resin-based composite materials. The specific process includes polymerization, spinning, pre-oxidation, low-temperature carbonization, high-temperature carbonization, surface treatment, water washing, and sizing Pre-drying, sizing, drying after sizing, winding and winding production processes. The specific process of this embodiment is the same as that of Examples 1-4, wherein the parameters of spinning, pre-oxidation, low-temperature carbonization, high-temperature carbonization, and sizing are different.

[0071] Step 1: Aggregation. Described polymerization production procedure is identical with the method described in embodiment 1~4 step 1, adopts sodium thiocyanate aqueous solution to carry out solution polymerization as solvent, wherein the parameter that polymerization production procedure changes is that the comonomer proportioning of solution polymerization reaction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com