Ultra-bright polyester medium-strength yarn and preparation method thereof

A technology of polyester and bright light, which is applied in filament/thread forming, single-component polyester artificial filament, fiber treatment, etc., and can solve problems such as refractory biodegradation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

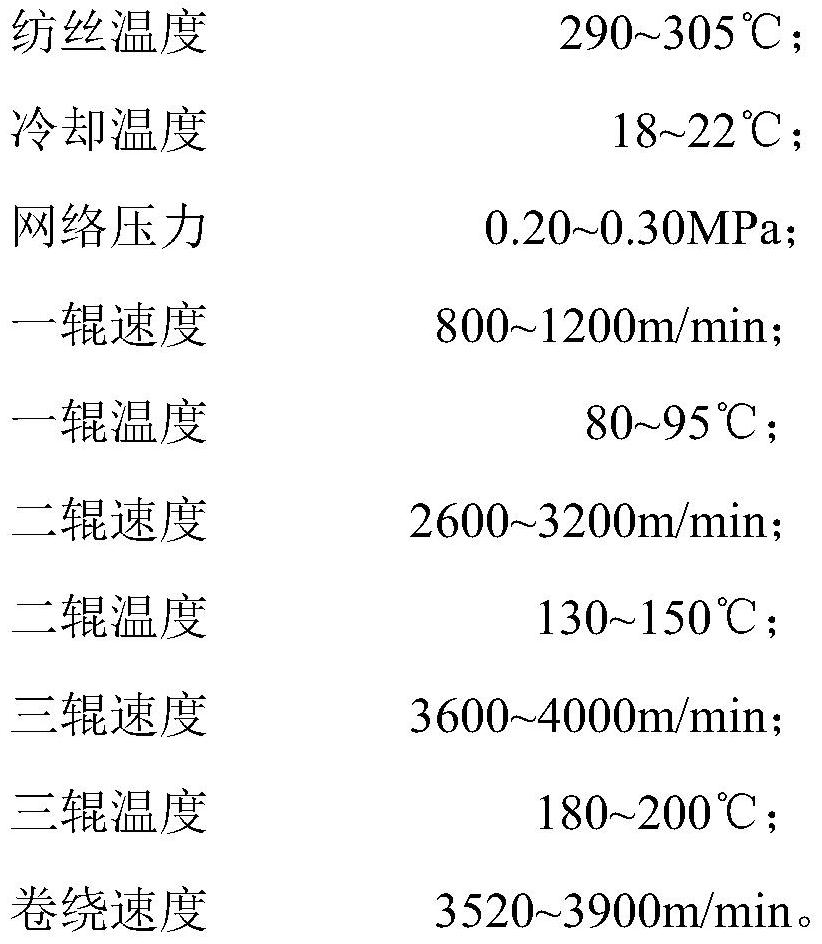

[0070] The preparation method of super bright polyester mid-strength yarn, the steps are as follows:

[0071] (1) prepare modified polyester;

[0072] (1.1) Esterification reaction;

[0073] Terephthalic acid, ethylene glycol, 2,2-difluoro-1,3-malonic acid, 3-trimethylsilyl-1,2-propanediol and 5-tert-butyl-1,3-benzenedicarboxylic acid Make a slurry, add antimony trioxide and triphenyl phosphate and mix evenly, pressurize in a nitrogen atmosphere to carry out esterification reaction, the pressurized pressure is 0.3MPa, the temperature of the esterification reaction is 250°C, when the esterification reaction The end point of the esterification reaction is when the amount of water distilled out reaches 90.1% of the theoretical value, and the molar ratio of terephthalic acid to ethylene glycol is 1:1.2, 2,2-difluoro-1,3-malonic acid , 3-trimethylsilyl-1,2-propanediol and 5-tert-butyl-1,3-benzenedicarboxylic acid add-on sum is 5mol% of terephthalic acid add-on amount, 2,2-difluor...

Embodiment 2

[0088] The preparation method of super-bright polyester mid-strength yarn, the steps are as follows:

[0089] (1) prepare modified polyester;

[0090] (1.1) Preparation of 3-trimethylsilyl-3-methyl-1,2-propanediol;

[0091] (a) Mix 3-trimethylsilyl-3-methylpropene, peracetic acid and dichloromethane at a molar ratio of 1:5:10, and react at a temperature of 35°C for 5 hours with stirring during the reaction. After the end, the solvent is removed, and trimethylsilylpropylene epoxide is obtained through purification and refining;

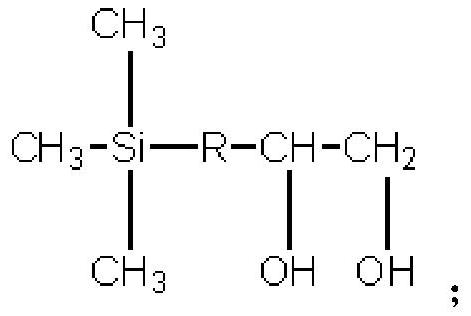

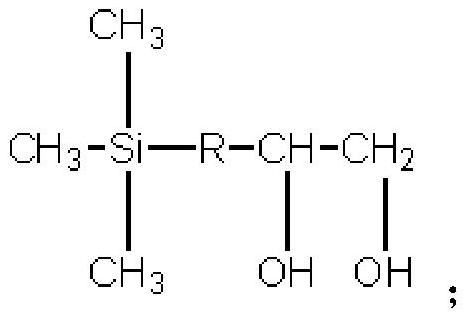

[0092] (b) Mix water, concentrated sulfuric acid and trimethylsilyl propylene epoxide, heat it in a water bath to 80°C under stirring conditions, keep it warm for 10 minutes, cool to room temperature after the reaction, and obtain the following formula after neutralization, distillation, separation and purification: The dihydric alcohol of band trimethylsilyl side group shown in formula (I), R in formula (I) is-CH(CH 3 )-, concentrated sulfuric acid...

Embodiment 3

[0106] The preparation method of super bright polyester mid-strength yarn, the steps are as follows:

[0107] (1) prepare modified polyester;

[0108] (1.1) Preparation of 3-trimethylsilyl-3-methyl-1,2-propanediol;

[0109] (a) Mix 3-trimethylsilyl-3-methylpropene, peracetic acid and dichloromethane at a molar ratio of 1:10:15, and react at a temperature of 40°C for 8 hours with stirring during the reaction. After the end, the solvent is removed, and trimethylsilylpropylene epoxide is obtained through purification and refining;

[0110] (b) Mix water, concentrated sulfuric acid and trimethylsilyl propylene epoxide, heat it in a water bath to 85°C under stirring conditions, keep it warm for 15 minutes, cool to room temperature after the reaction, and obtain the following formula after neutralization, distillation, separation and purification: The dihydric alcohol of band trimethylsilyl side group shown in formula (I), R in formula (I) is-CH(CH 3 )-, concentrated sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com