Polypropylene composite material with higher toughness at low temperature and preparation method of composite material

A composite material and polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of poor low-temperature toughness, etc., and achieve the effects of good thermal stability, high tensile capacity, and good low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

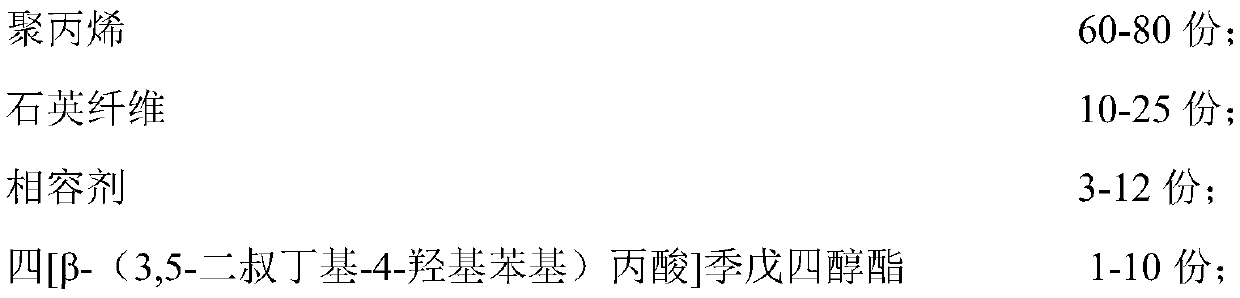

[0022] A polypropylene composite material with high toughness at low temperature, comprising the following raw material components and parts by weight:

[0023]

[0024]

[0025] Among them, the length of the quartz fiber is 18mm, the diameter of the single filament is 10μm, and the density is 2.58g / cm 3 , The softening point is 620°C.

[0026] The density of maleic anhydride grafted polypropylene is 0.81g / cm 3 , the grafting rate is 1.9%, the melt index is 52g / 10min (190°C, 2.16kg), the tensile strength is 28MPa, and the melting point is 148°C.

[0027] A method for preparing a polypropylene composite material with high toughness at low temperature, comprising the following steps:

[0028] (1) Polypropylene, quartz fiber, maleic anhydride grafted polypropylene, and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester are added according to the ratio of raw materials Mix evenly in a high-speed mixer, where the mixing temperature is 80-100°C...

Embodiment 2

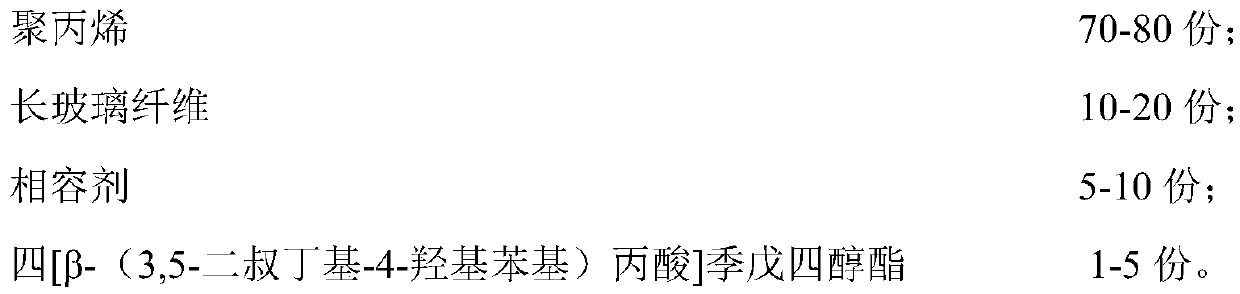

[0063] A polypropylene composite material with high toughness at low temperature, comprising the following raw material components and parts by weight:

[0064]

[0065] Among them, the length of the quartz fiber is 18mm, the diameter of the single filament is 10μm, and the density is 2.58g / cm 3 , The softening point is 620°C.

[0066] The density of maleic anhydride grafted polypropylene is 0.81g / cm 3 , the grafting rate is 1.9%, the melt index is 52g / 10min (190°C, 2.16kg), the tensile strength is 28MPa, and the melting point is 148°C.

[0067] A method for preparing a polypropylene composite material with high toughness at low temperature, comprising the following steps:

[0068] (1) Polypropylene, quartz fiber, maleic anhydride grafted polypropylene, and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester are added according to the ratio of raw materials Mix evenly in a high-speed mixer, where the mixing temperature is 80-100°C;

[0069] ...

Embodiment 3

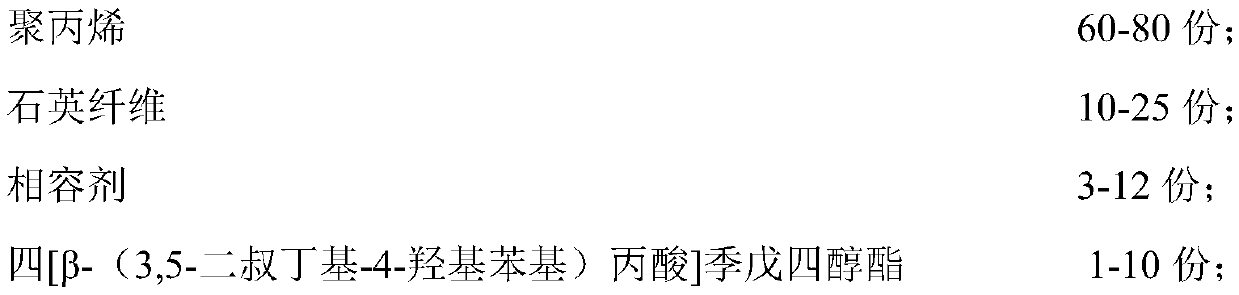

[0103] A polypropylene composite material with high toughness at low temperature, comprising the following raw material components and parts by weight:

[0104]

[0105] Among them, the length of the quartz fiber is 18mm, the diameter of the single filament is 10μm, and the density is 2.58g / cm 3 , The softening point is 620°C.

[0106] The density of maleic anhydride grafted polypropylene is 0.81g / cm 3 , the grafting rate is 1.9%, the melt index is 52g / 10min (190°C, 2.16kg), the tensile strength is 28MPa, and the melting point is 148°C.

[0107] A method for preparing a polypropylene composite material with high toughness at low temperature, comprising the following steps:

[0108] (1) Polypropylene, quartz fiber, maleic anhydride grafted polypropylene, and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester are added according to the ratio of raw materials Mix evenly in a high-speed mixer, where the mixing temperature is 80-100°C;

[0109] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com