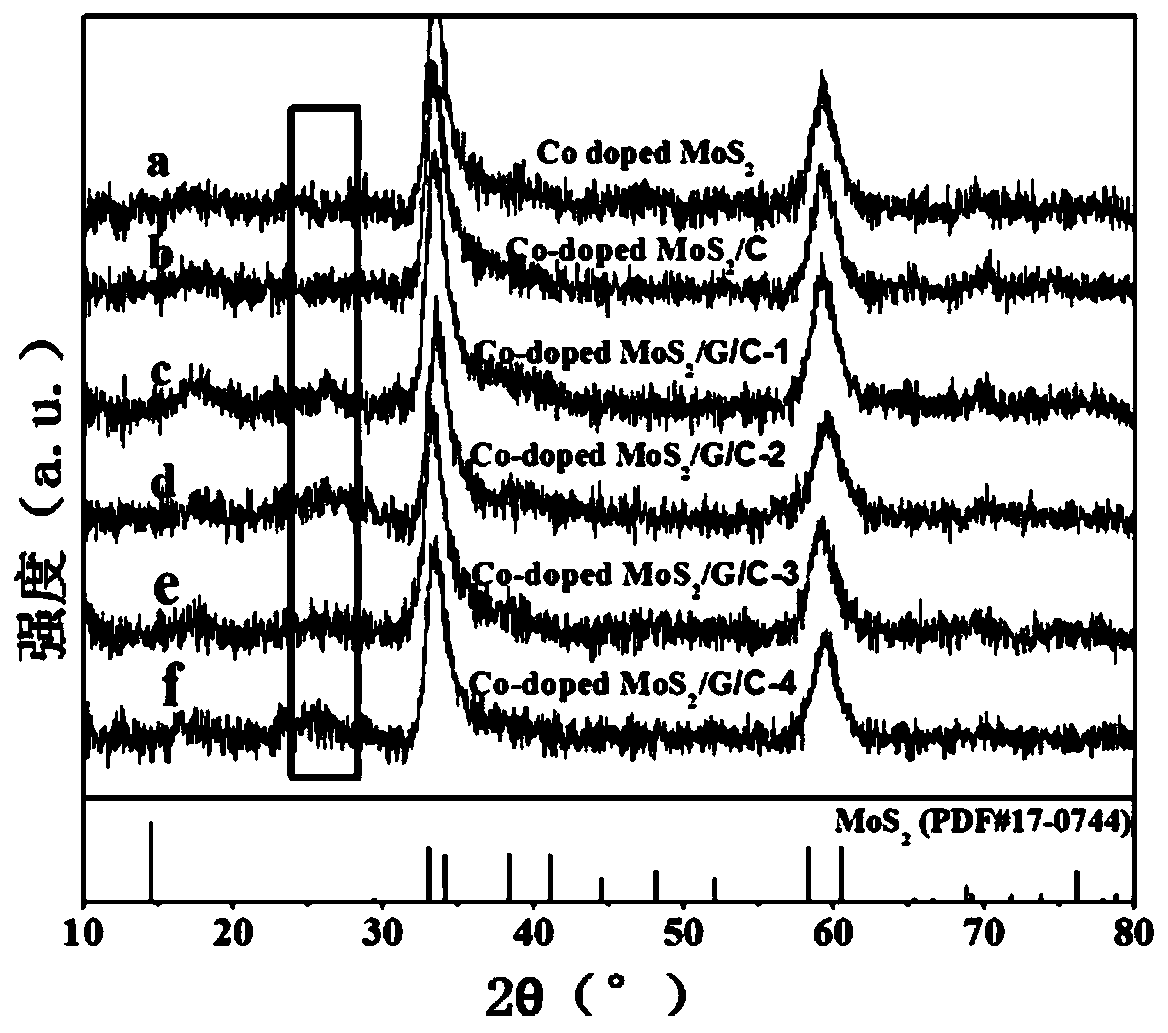

Cobalt-doped molybdenum sulfide-graphene-carbon composite material, and preparation method and application thereof

A carbon composite material and molybdenum sulfide technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of MoS2 shape and structure, difficult to control stable crystal phase structure, etc. , good large-scale application potential, excellent charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Measure 35mL, 0.05mol / L glucose solution, take 0.05g graphite oxide powder and disperse in a certain amount of glucose solution, fully ultrasonic for 1h; add 0.2g sodium molybdate and stir for 10min, weigh 0.015g cobalt acetate and ultrasonically stir 15min, add 0.4g thiourea and stir until completely dissolved. Put it into a reactor and react in a 200°C hydrothermal box for 24 hours. Cool to room temperature and centrifuge to collect the product (washed twice with ethanol). Dry and sinter with argon at 600°C for 3h.

[0032] After fully grinding the sintered material, mix it with carbon black and carboxymethyl cellulose at a ratio of 70:15:15, and dry it in vacuum at 60° C. for 4 hours after coating to prepare a composite electrode. Put the electrode in the 2025 battery shell, use the sodium sheet as the counter electrode, use the polyethylene film as the diaphragm, and use 1M NaClO 4 In EC:EMC:DMC (volume ratio 1 / 1 / 1)+5%FEC, the electrolyte assembled battery was us...

Embodiment 2

[0034] Measure 35mL, 0.02mol / L fructose solution, take 0.005g of graphite oxide powder and disperse in a certain amount of glucose solution, fully ultrasonic for 1h; add 0.1g of sodium molybdate and stir for 10min, weigh 0.015g of cobalt acetate and ultrasonically stir 15min, add 0.5g thiourea and stir until completely dissolved. Put it into a reactor and react for 10 hours in a 220°C hydrothermal box. Cool to room temperature and centrifuge to collect the product (washed twice with ethanol). Dry and sinter in He gas at 400°C for 12h.

[0035]After fully grinding the sintered material, mix it with carbon black and carboxymethyl cellulose at a ratio of 70:15:15, and dry it in vacuum at 70° C. for 4 hours after coating to prepare a composite electrode. Put the electrode in the 2025 battery case, use the lithium sheet as the counter electrode, use the polyethylene film as the separator, and use 1M LiPF 6 EC / DEC (v / v=1 / 1) conducts constant current charge and discharge tests for...

Embodiment 3

[0037] Measure 35mL, 0.05mol / L sucrose solution, take 0.1g of graphite oxide powder and disperse in a certain amount of glucose solution, fully ultrasonic for 1h; add 1g of sodium molybdate and stir for 10min, weigh 0.025g of cobalt acetate and ultrasonically stir for 15min , Add 2g of thiourea and stir until completely dissolved. Put it into a reactor and react for 48 hours in a 150°C hydrothermal box. Cool to room temperature and centrifuge to collect the product (washed twice with ethanol). Drying, 800℃Ar / H 2 Mixed gas sintering 12h.

[0038] After fully grinding the sintered material, mix it with carbon black and carboxymethyl cellulose at a ratio of 70:15:15, and dry it in vacuum at 60° C. for 4 hours after coating to prepare a composite electrode. Put the electrode in the 2025 battery shell, use the sodium sheet as the counter electrode, use the polyethylene film as the diaphragm, and use 1M NaClO 4 In EC:EMC:DMC (volume ratio 1 / 1 / 1)+5%FEC, the electrolyte assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com