Method for producing umami peptide by staging fed-batch fermentation

A technology of fed-feed fermentation and umami-flavored peptides is applied in the field of segmented feed-feed fermentation to produce umami-flavored peptides, which can solve problems such as difficulties in industrial production of umami-flavored peptides, and achieve the effects of avoiding substrate inhibition and increasing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

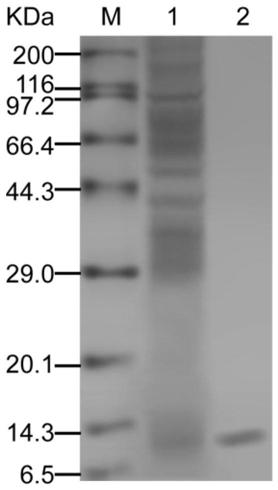

[0020] Example 1: Construction of highly efficient self-induced production strains of umami peptides

[0021] Using the umami peptide recombinant plasmid vector constructed in the patent CN108148116A as a PCR template, the homology arm design of the self-inducible promoter srfA was carried out by using the whole plasmid PCR, so as to construct a recombinant plasmid for highly self-inducible expression of umami peptide. The gene sequence of the self-inducible promoter srfA is shown in SEQ ID NO.1, and the design results of the homology arm sequence of the whole plasmid PCR are shown in Table 1. The umami peptide self-inducible expression vector was obtained by using the whole plasmid PCR amplification technology to obtain Vector plasmid pMA09srfA-10SSRDEQSR with an autoinducible expression promoter.

[0022] Table 1 Homology arm sequence of whole plasmid PCR

[0023]

[0024] Prepare B. subtilis WB800 competent cells by starvation chemical method, add 10 μl of freshly const...

Embodiment 2

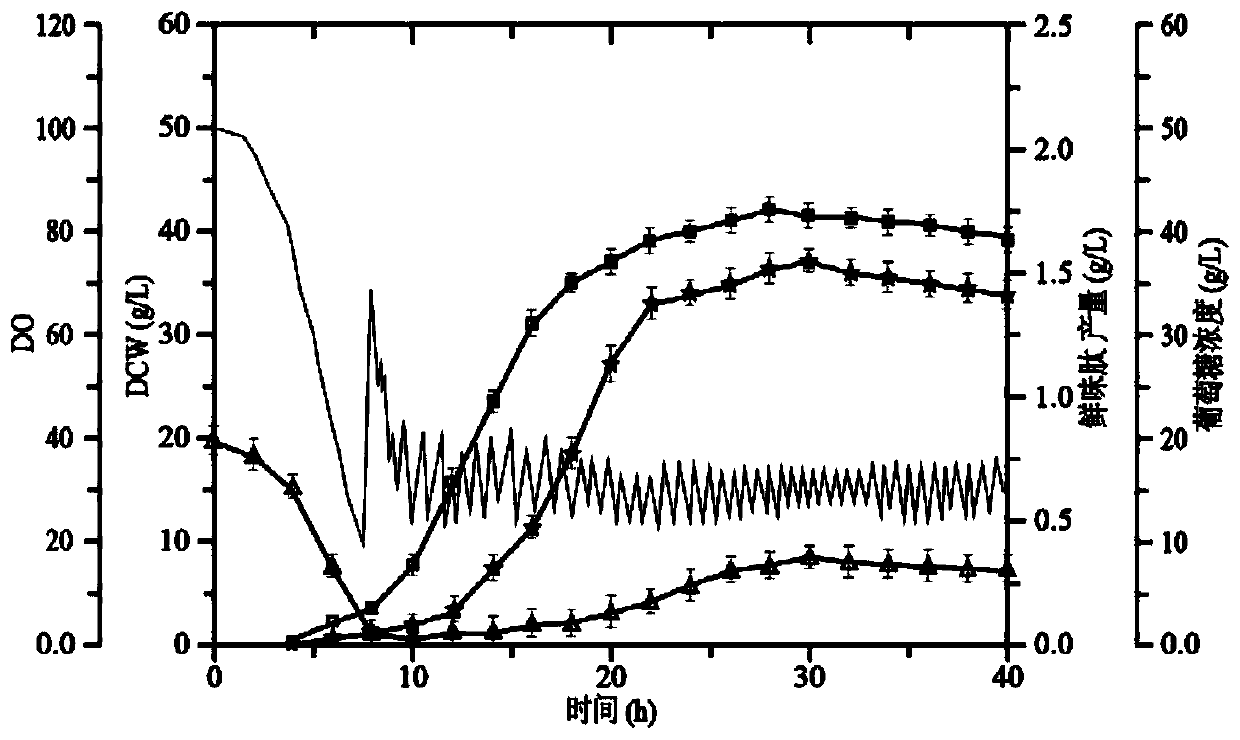

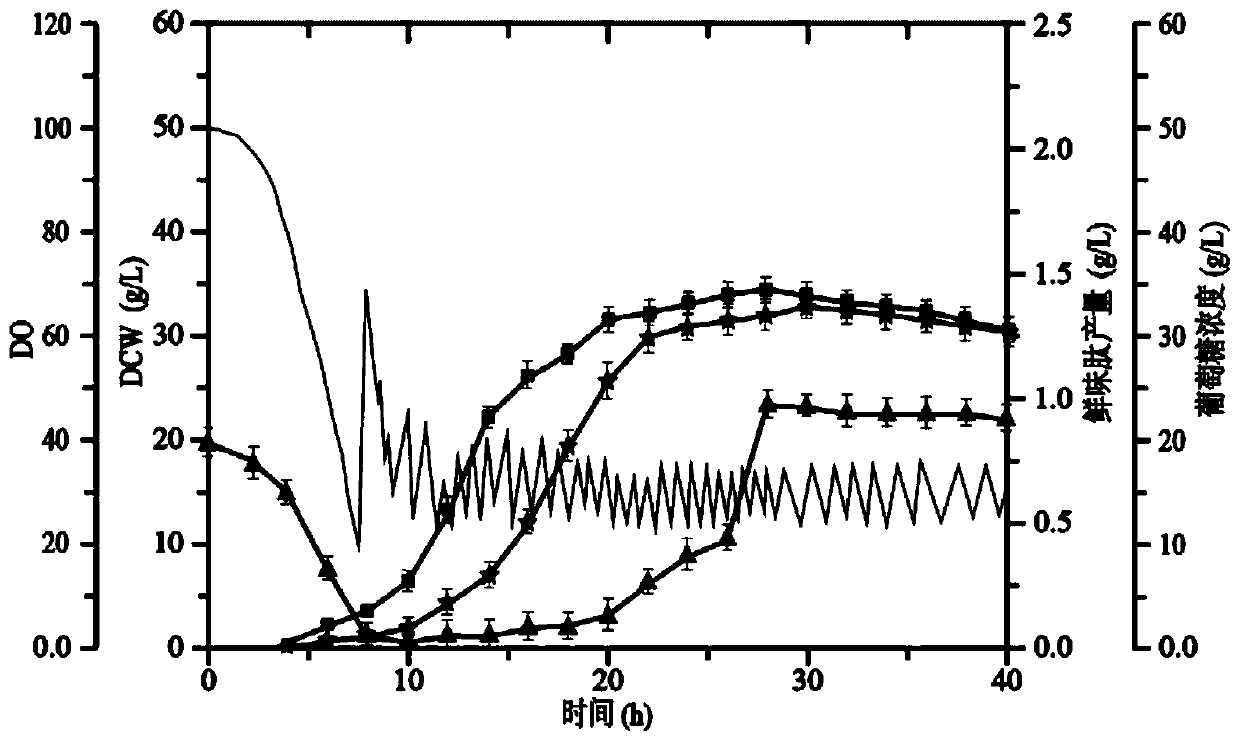

[0026] Example 2: Production of umami peptides by multi-stage μ value regulation index fed-batch fermentation

[0027] 1. Culture medium used for production

[0028] LB solid medium (g / L): tryptone 10, yeast extract 5, sodium chloride 10, agar powder 15.

[0029] LB liquid medium (g / L): tryptone 10, yeast extract 5, sodium chloride 10.

[0030] Basic fermentation medium (g / L): diammonium hydrogen citrate 7.5, sodium sulfate 2.0, ammonium sulfate 20.0, ammonium chloride 3.5, dipotassium hydrogen phosphate 14.6, sodium dihydrogen phosphate monohydrate 4.0, magnesium sulfate heptahydrate 1.0, Trace metal ion solution 3.0mL, glucose 20.0 (sterilized separately).

[0031] Trace metal ion solution (g / L): calcium chloride 0.5, zinc sulfate heptahydrate 0.18, manganese sulfate monohydrate 0.1, disodium edetate 10.05, ferric chloride 8.35, copper sulfate pentahydrate 0.16, chlorine hexahydrate Cobalt 0.18.

[0032] Feed medium (g / L): glucose 800.

[0033] 2. Expansion of seed cult...

Embodiment 2

[0040] Table 2 Example 2 multi-stage μ value control strategy

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com