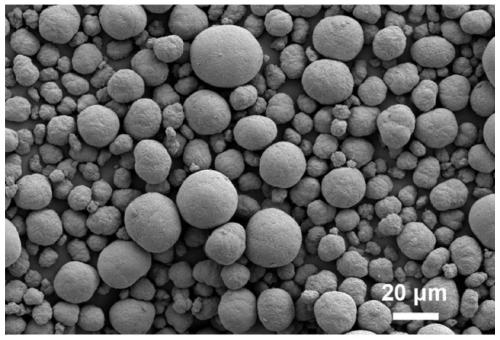

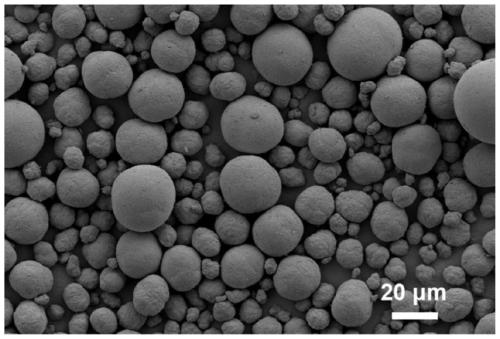

A kind of ultra-large particle size nickel-cobalt-manganese hydroxide for energy storage and preparation method thereof

A technology of hydroxide and nickel-cobalt-manganese, applied in the direction of manganese oxide/manganese hydroxide, cobalt oxide/cobalt hydroxide, nickel oxide/nickel hydroxide, etc. It can improve the tap density, avoid particle cracking and improve the compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Select nickel sulfate, cobalt sulfate and manganese sulfate, and prepare a mixed metal salt solution with a total metal ion concentration of 2.5mol / L according to the molar ratio of Ni:Co:Mn of 0.55:0.20:0.25; the prepared concentration is 8.0mol / L The sodium hydroxide solution is used as a precipitating agent; the ammonia solution with a concentration of 8.0mol / L is prepared as a complexing agent.

[0036] 2. Feed nitrogen into the 5000L sealed reaction kettle with stirring and temperature control device, the flow rate is 1200L / h, add 2000L bottom liquid; the added bottom liquid is ammonia concentration of 3g / L, pH value of 12.2, temperature of 60°C aqueous solution. Start stirring, continue and feed nitrogen into the reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process, with a flow rate of 1200 L / h.

[0037]3. Add the mixed metal salt solution, sodium hydroxide solution and ammonia solution prepared in step 1 into ...

Embodiment 2

[0046] 1. Select nickel sulfate, cobalt sulfate and manganese sulfate, and prepare a mixed metal salt solution with a total metal ion concentration of 2.0mol / L according to the molar ratio of Ni:Co:Mn of 0.52:0.20:0.28; the prepared concentration is 6.0mol / L The sodium hydroxide solution is used as a precipitating agent; the ammonia solution with a concentration of 7mol / L is prepared as a complexing agent.

[0047] 2. Feed nitrogen into the 5000L sealed reaction kettle with stirring and temperature control device, the flow rate is 1800L / h, add 4000L bottom liquid; the added bottom liquid is ammonia concentration of 3g / L, pH value of 12.0, temperature of Aqueous solution at 57°C. Start stirring, continue and feed nitrogen into the reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process, with a flow rate of 1800 L / h.

[0048] 3. Add the mixed metal salt solution, sodium hydroxide solution and ammonia solution prepared in step 1 int...

Embodiment 3

[0057] 1. Select nickel sulfate, cobalt sulfate and manganese sulfate, and prepare a mixed metal salt solution with a total metal ion concentration of 2.0mol / L according to the molar ratio of Ni:Co:Mn of 0.50:0.20:0.30; the prepared concentration is 5.0mol / L The sodium hydroxide solution is used as a precipitating agent; the ammonia solution with a concentration of 5.5mol / L is prepared as a complexing agent.

[0058] 2. Feed nitrogen into the 5000L sealed reaction kettle with stirring and temperature control device, the flow rate is 2200L / h, add 3000L bottom liquid; the added bottom liquid is ammonia concentration of 4g / L, pH value of 12.2, temperature of Aqueous solution at 55°C. Start stirring, continue to feed nitrogen into the reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process, with a flow rate of 2200 L / h.

[0059] 3. Add the mixed metal salt solution, sodium hydroxide solution and ammonia solution prepared in step 1 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com