High reliability PTC thermistor

A thermistor and reliability technology, applied in the direction of non-adjustable metal resistors, resistors, resistors with positive temperature coefficients, etc., can solve the problems of low device reliability, low withstand voltage level, device failure, etc. , to prevent the infiltration of water and water vapor, ensure safety performance, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-reliability PTC thermistor, comprising a PTC chip, a first electrode pasted on the upper surface of the PTC chip, a second electrode pasted on the lower surface of the PTC chip, and soldered to the surfaces of the first electrode and the second electrode Electrode leads, the leads are tinned leads; the diameter of the leads is 0.3mm, the bottom of the leads is provided with an overload protector, and the outer side of the welding part of the PTC chip, the first electrode, the second electrode and the leads is wrapped with an encapsulation layer from inside to outside , the encapsulation layer is a glass layer; there is a gap between the PTC chip and the encapsulation layer;

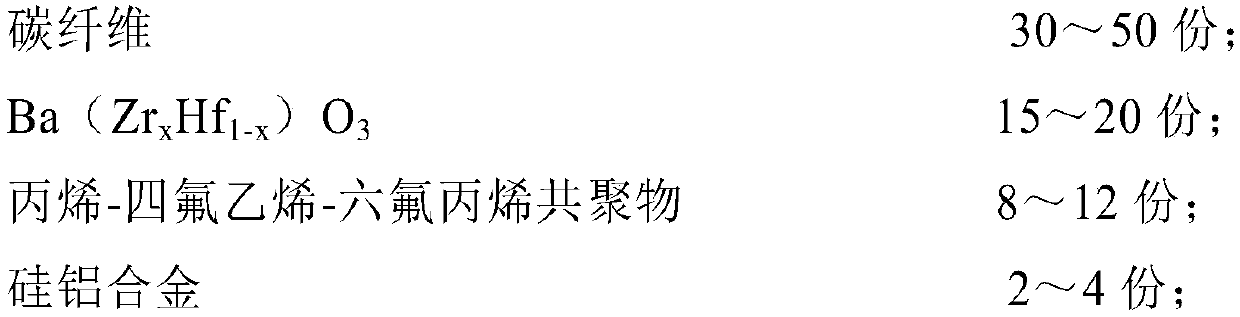

[0037] Wherein, the PTC chip includes the following materials by weight:

[0038]

[0039]

[0040] A cooling layer is provided outside the encapsulation layer, and the cooling layer includes 30wt% bamboo fiber, 30wt% titanium dioxide, 20wt% barium sulfate, and 20wt% zinc oxide. A moi...

Embodiment 2

[0043] A high-reliability PTC thermistor, which includes a PTC chip, a first electrode attached to the upper surface of the PTC chip, a second electrode attached to the lower surface of the PTC chip, and welded to the first electrode and the second electrode The electrode leads on the surface are tin-plated leads with a diameter of 0.6mm. An overload protector is installed at the bottom of the leads. The encapsulation layer, the encapsulation layer is a glass layer; there is a gap between the PTC chip and the encapsulation layer;

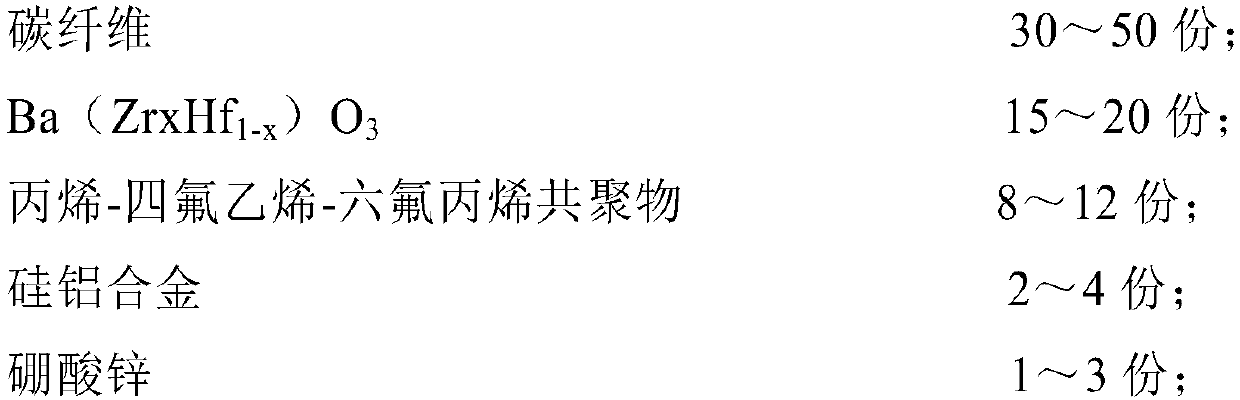

[0044] Wherein, the PTC chip includes the following materials by weight:

[0045]

[0046]A cooling layer is provided outside the encapsulation layer, and the cooling layer includes 40wt% bamboo fiber, 20wt% titanium dioxide, 22wt% barium sulfate, and 18t% zinc oxide. A moisture-proof layer is also provided outside the cooling layer, and the moisture-proof layer is an acrylic resin layer. The gap is provided with an explosion-proof layer; the e...

Embodiment 3

[0048] A high-reliability PTC thermistor, comprising a PTC chip, a first electrode pasted on the upper surface of the PTC chip, a second electrode pasted on the lower surface of the PTC chip, and soldered to the surfaces of the first electrode and the second electrode Electrode leads, the leads are tinned leads; the diameter of the leads is 0.4mm, the bottom of the leads is provided with an overload protector, and the outer side of the welding part of the PTC chip, the first electrode, the second electrode and the leads is wrapped with an encapsulation layer from inside to outside ; There is a gap between the PTC chip and the encapsulation layer;

[0049] Wherein, the PTC chip includes the following materials by weight:

[0050]

[0051] A cooling layer is provided outside the encapsulation layer, and the cooling layer includes 35wt% bamboo fiber, 25wt% titanium dioxide, 25wt% barium sulfate, and 15wt% zinc oxide. A moisture-proof layer is also provided outside the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com