A kind of high temperature resistant composite transparent conductive film and preparation method thereof

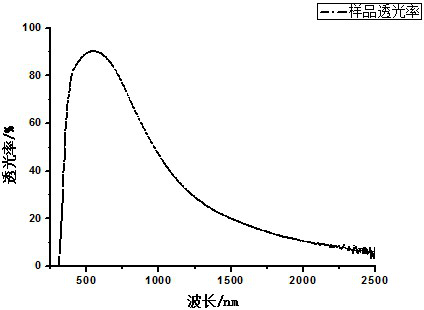

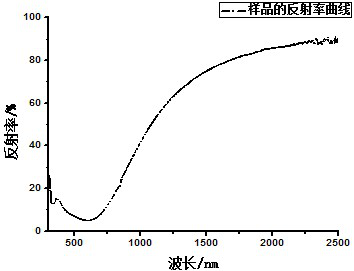

A technology of transparent conductive film and high temperature resistance, applied to the conductive layer on the insulating carrier, equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, etc., can solve the problem of poor conductivity, failure, The color of the transparent conductive film deviates from the neutral color, etc., to achieve the effect of excellent light transmittance, low cost, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of high temperature resistant and transparent composite transparent conductive film, the structure of the film layer is shown in the appendix figure 1 . Including transparent substrate 7, ion barrier layer 1 (SiNx), buffer layer 2 (SnO 2 / ITO), inner metal protective layer 3 (Ti), metal layer 4 (Ag), outer metal protective layer 5 (Ti), functional layer 6 (ZrO 2 / SiO 2 );

[0039] The thickness of the transparent substrate 7 is 3.2 mm, the thickness of the ion barrier layer 1 is 20nm~30nm, the thickness of the buffer layer 2 is 20~50nm, the thickness of the Ti layer of the inner metal protective layer 3 is 0.2~1.5nm, and the thickness of the metal layer 4 is 7~50nm. 14nm, the Ti layer thickness of the outer metal protective layer 5 is 0.2~1.5 nm, and the thickness of the functional layer 6 is 20~80nm;

[0040] The specific operation steps are as follows:

[0041] 1) Clean the transparent substrate 7 with a corresponding size and thickness of 3.2mm, and set t...

Embodiment 2

[0055] The film layer structure of the composite transparent conductive film is attached figure 1 . Including transparent substrate 7, ion barrier layer 1 (SiAlNx), buffer layer 2 (ZnSnOx / ZnO), inner metal protection layer 3 (Ti), metal layer 4 (Ag), outer metal protection layer 5 (NiCr), function Layer 6 (SnO 2 / AZO / ITO / SiZrOx);

[0056] The thickness of the transparent substrate 7 is 4 mm, the thickness of the ion barrier layer 1 is 10-50 nm, the thickness of the buffer layer 2 is 20-50 nm, the thickness of the inner metal protective layer 3 is 0.2-1.5 nm, and the thickness of the metal layer 4 is 7-14 nm , the outer metal protection layer 5 has a thickness of 0.2-1.5 nm, and the functional layer 6 has a thickness of 20-80 nm;

[0057] The specific operation steps are as follows:

[0058] 1) Clean the transparent substrate 7 with a thickness of 4mm of the corresponding size, and set the vacuum degree of the offline magnetron sputtering equipment at 10 -3 Pa, the line s...

Embodiment 3

[0070] See the attached film structure figure 1 . Including transparent substrate 7, ion barrier layer 1 (BiOx), buffer layer 2 (SnO2 / AZO), inner metal protection layer 3 (TiV), metal layer 4 (AgCu), outer metal protection layer titanium 5 (Ti), Functional layer 6 (AZO / ITO / TiO 2 ).

[0071] The transparent substrate 7 has a thickness of 3.2 mm, the ion barrier layer 1 has a thickness of 10-20 nm, the buffer layer 2 has a thickness of 20-80 nm, the inner metal protective layer 3 has a thickness of 0.2-0.9 nm, and the metal layer 4 has a thickness of 7-14 nm. The outer metal protective layer 5 has a thickness of 0.5-1.2 nm, and the functional layer 6 has a thickness of 20-80 nm;

[0072] The specific operation steps are as follows:

[0073] 1) Clean the ultra-white transparent substrate 7 with a thickness of 3.2mm of the corresponding size, and set the vacuum degree of the offline magnetron sputtering equipment at 10 -3 Pa, the line speed is set to 4.0 m / min;

[0074] 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com