Tantalum atom doped bioactive ceramic coating prepared on titanium alloy surface and preparation method thereof

A technology of bioactive ceramics and titanium alloys, applied in surface reaction electrolytic coating, metal material coating process, coating and other directions, can solve the problems of inability to prepare coating on sample surface, introduction of functional element Ta, and difficulty in promotion, etc. To achieve the effect of facilitating large-scale preparation, promoting proliferation and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

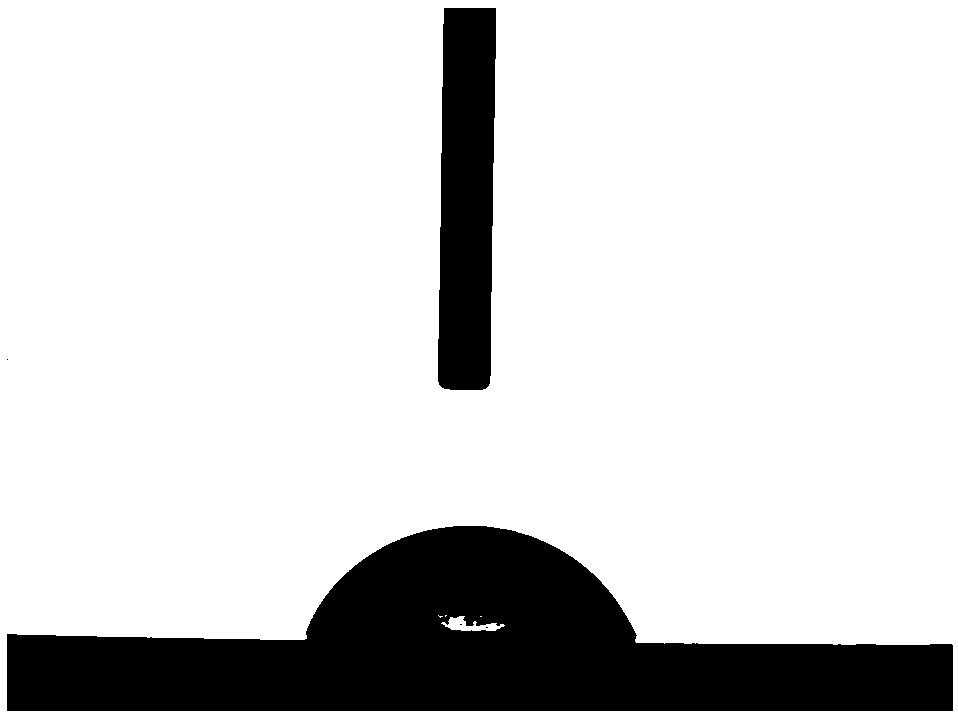

Image

Examples

Embodiment 1

[0036] Under the condition of stirring, slowly add 4.5g of tantalum pentachloride into 100mL of ethanol, and continue to stir for 0.5 hours. Then, 2.0 mL of acetylacetone and 3.0 mL of concentrated nitric acid aqueous solution (65% by mass) were added to the above solution, and the stirring was continued for 0.5 hours. Then 3 mL of hydrogen peroxide aqueous solution (30% by mass) was added dropwise, and after stirring for 1 hour, the resulting solution was sealed and aged at 5° C. for 5 days.

[0037]Add 1.7 mL of concentrated phosphoric acid aqueous solution (mass fraction 85%) and 0.3 mL of hydrofluoric acid aqueous solution (mass fraction 40%) into 50 mL of water. The titanium sheet was etched in the solution for 10 minutes, then the titanium sheet was taken out, washed with distilled water and blown dry with nitrogen. Place the corroded titanium sheet in the aged tantalum sol for 3 minutes, then slowly take out the titanium sheet, dry it at room temperature and place it i...

Embodiment 2

[0040] Add 4.5g of diamine hydrogen phosphate and 40g of calcium acetate into 1.0L of deionized water to prepare a micro-arc oxidation electrolyte, and then immerse the titanium sheet coated with tantalum sol in it. The reaction process uses a positive pulse voltage of 380V, a negative voltage of 80V, a frequency of 200HZ, a duty cycle of 15%, and a working time of 2 minutes, and the temperature of the electrolyte is controlled at 20°C. The rest of the operations are the same as in Example 1; Ultrasonic cleaning with distilled water and drying with nitrogen gas to prepare a bioactive ceramic coating doped with tantalum atoms on the surface of the titanium alloy.

Embodiment 3

[0042] While stirring, slowly add 2.0 g of tantalum ethoxide into 50 mL of ethanol solvent, and continue stirring for 0.5 hours. Then, 1.0 mL of acetylacetone and 1.0 mL of concentrated nitric acid aqueous solution (65% by mass) were added to the above solution, and the stirring was continued for 0.5 hours. Then an aqueous hydrogen peroxide solution (30% by mass) was added dropwise, and after stirring for 1 hour, the resulting solution was sealed and aged at 0° C. for 3 days.

[0043] Add 3.0 mL of concentrated phosphoric acid aqueous solution (mass fraction 85%) and 0.4 mL of hydrofluoric acid aqueous solution (mass fraction 40%) into 50 mL of water. The titanium sheet was etched in the solution for 10 minutes, then the titanium sheet was taken out, washed with distilled water and blown dry with nitrogen. Place the corroded titanium sheet in the aged tantalum sol for 4 minutes, then slowly take out the titanium sheet, dry it at room temperature and place it in an oven at 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com