A kind of anti-perovskite manganese nitrogen compound/aluminum composite material and preparation method thereof

A technology of manganese nitrogen compound and aluminum composite material, which is applied in the field of antiperovskite manganese nitrogen compound/aluminum composite material and its preparation, can solve the problems of poor mechanical properties, high temperature, low thermal conductivity, etc., and achieve high thermal conductivity, Low thermal expansion coefficient, the effect of reducing the interface reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode 1: In this implementation mode, the antiperovskite manganese nitrogen compound / aluminum composite material is composed of a reinforcement and a matrix metal, and the reinforcement is GaNMn 3 Particles, the base metal is pure aluminum or aluminum alloy.

[0021] The principles and beneficial effects of this embodiment are:

[0022] 1. The base metal such as Cu has a high melting point, so it needs a higher recombination temperature. At high temperature, the base metal and GaNMn 3 The interfacial reaction is large during the recombination process of the reinforcement, and GaNMn 3 The composition of the reinforcement is prone to change and the negative thermal expansion properties will disappear. Compared with other base metals such as Cu, Al has a lower melting point, so this embodiment uses GaNMn 3 Combining with aluminum can lower the reaction temperature and reduce the interface reaction. This embodiment uses GaNMn 3 As an enhancer, in...

specific Embodiment approach 2

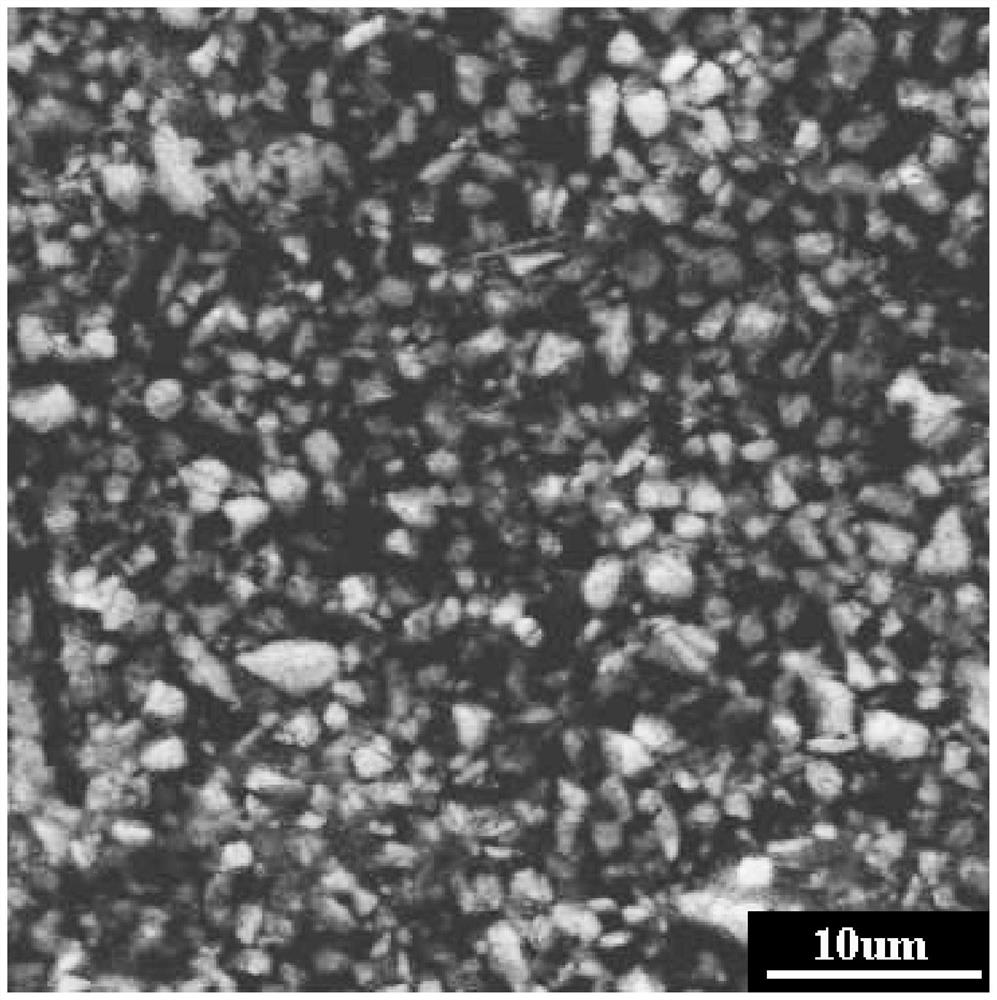

[0026] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the GaNMn 3The particle size of the particles is 1-5 μm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the volume fraction of the reinforcement in the anti-perovskite manganese nitride / aluminum composite material is 20-30%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com