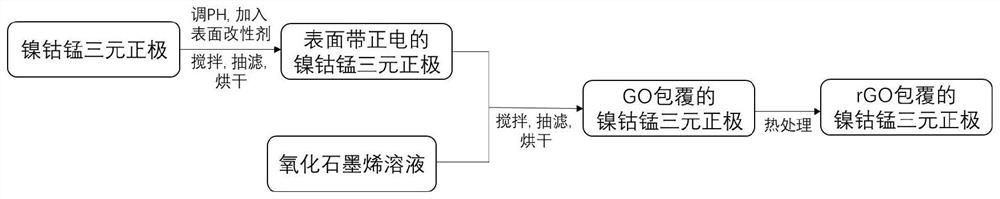

Preparation method of reduced graphene oxide modified nickel-cobalt-manganese ternary positive electrode material

A nickel-cobalt-manganese ternary, cathode material technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of low charging and discharging efficiency of high nickel ternary materials, affecting the stability of lithium-ion batteries, materials Structural instability and other problems, to achieve excellent rate and cycle performance, unique electron transport kinetics, easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

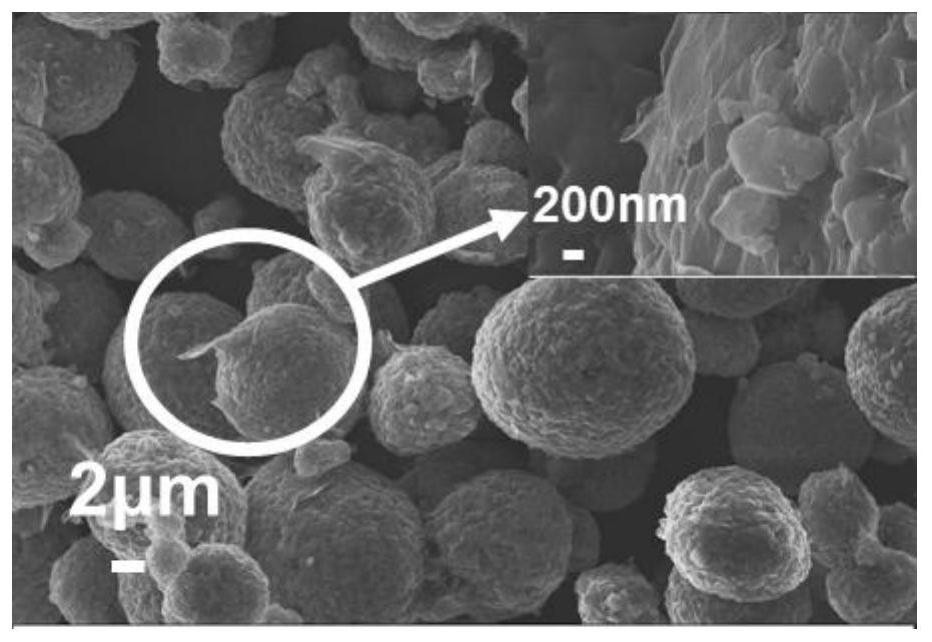

[0025] Will LiNi 0.8 co 0.1 mn 0.1 o 2 Add ethanol solution to obtain raw material dispersion, add ammonia solution to adjust to PH=9, immediately add surface modifier γ-aminopropyltriethoxysilane, the mass is 1wt% of the raw material dispersion. Stir magnetically at room temperature for half an hour, then filter with suction, and wash off excess modifier and solvent with ethanol. The graphene oxide solution consists of a mass of LiNi 0.8 co 0.1 mn 0.1 o 2 1wt% of the raw material was dissolved in ethanol and then ultrasonically treated for 4h to obtain the above-mentioned modified LiNi 0.8 co 0.1 mn 0.1 o 2 The raw materials were dissolved in 10ml of ethanol, and added dropwise to the graphene oxide solution placed on a magnetic stirring table, stirred for half an hour, suction filtered, washed, and dried in an oven at 50°C to remove the solvent to obtain graphene oxide coating modification LiNi 0.8 co 0.1 mn 0.1 o 2 . The temperature was raised to 300°C at a ...

Embodiment 2

[0027] The addition ratio of graphene oxide is increased to 2wt%, other conditions are the same as embodiment 1.

Embodiment 3

[0029] The addition ratio of graphene oxide is increased to 2wt%, other conditions are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com