Hydrophobic easy-to-clean powder coating

A powder coating, easy-to-clean technology, applied in the field of coatings, can solve the problems of high raw material cost, unfavorable industrial application, and decreased product surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

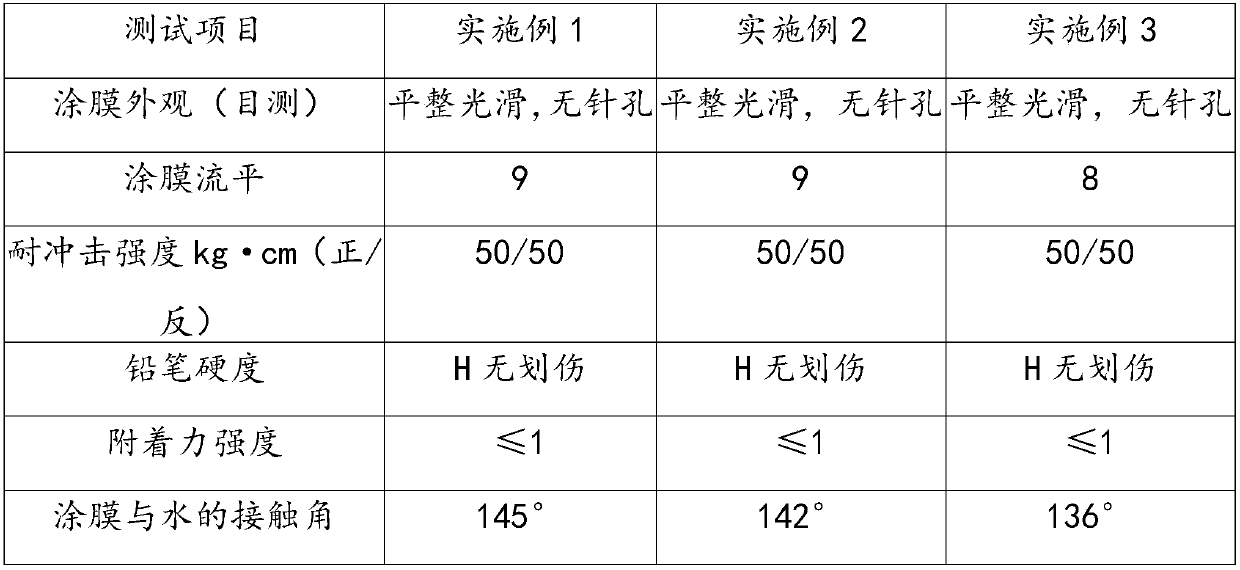

Examples

Embodiment 1

[0028] (1) The preparation process of organosilane-modified saturated hydroxyl-terminated polyester resin is as follows:

[0029] ① Mixing of raw materials: Add 353g of isophthalic acid, 147g of ethylene glycol, 100g of hydroxy silicone oil and 400g of xylene into the reaction vessel, raise the temperature to 100°C, and wait until the materials are completely dissolved;

[0030] ②Polymerization reaction: After stirring the reaction system and raising the temperature to 180°C, add 0.5g of tetrabutyl titanate dropwise to the reaction vessel under the protection of nitrogen, and keep it warm for 2h of polymerization reaction;

[0031] ③Post-processing: Use atmospheric pressure and vacuum distillation to remove the solvent, pour the material into an aluminum pan while it is hot, cool, and pulverize to obtain the organosilicon-modified saturated hydroxyl-terminated polyester resin of the present invention, and measure the hydroxyl value It is 37mgKOH / g.

[0032] (2) A high-toughne...

Embodiment 2

[0046] (1) The preparation process of organosilane-modified saturated hydroxyl-terminated polyester resin is as follows:

[0047] ① Mixing of raw materials: Add 347g of succinic acid, 243g of 1,2-propanediol, 150g of hydroxy silicone oil and 250g of xylene into the reaction vessel, raise the temperature to 110°C, and wait until the materials are completely dissolved;

[0048] ②Polymerization reaction: Stir the reaction system and raise the temperature to 190°C, then add the catalyst dropwise to the reaction vessel under the protection of nitrogen, and keep warm for 2.5 hours to carry out the polymerization reaction;

[0049] ③Post-processing: use normal pressure and reduced pressure distillation to remove solvent, pour the material into an aluminum pan while it is hot, cool and pulverize to obtain the organosilicon-modified saturated hydroxyl-terminated polyester resin of the present invention, and measure the hydroxyl value It is 52mgKOH / g.

[0050] (2) A self-cleaning powde...

Embodiment 3

[0064] (1) The preparation process of organosilane-modified saturated hydroxyl-terminated polyester resin is as follows:

[0065] ①Raw material mixing: Add 372g of glutaric acid, 328g of neopentyl glycol, 200g of hydroxy silicone oil and 100g of xylene into the reaction vessel, raise the temperature to 120°C, and wait until the materials are completely dissolved;

[0066] ②Polymerization reaction: After stirring the reaction system and raising the temperature to 210°C, add the catalyst dropwise to the reaction vessel under the protection of nitrogen, and keep warm for 3h of polymerization reaction;

[0067]③Post-processing: use normal pressure and reduced pressure distillation to remove solvent, pour the material into an aluminum pan while it is hot, cool and pulverize to obtain the organosilicon-modified saturated hydroxyl-terminated polyester resin of the present invention, and measure the hydroxyl value It is 42mgKOH / g.

[0068] (2) A self-cleaning powder coating comprisin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com