Finishing-free composite binding agent ultrahard grinding wheel for silicon ingot grinding and preparation method and application of finishing-free composite binding agent ultrahard grinding wheel

A composite bonding agent and grinding technology, which is used in grinding/polishing equipment, grinding devices, grinding machines, etc., can solve the problem that large depth of cut and rapid feed cannot be achieved in the grinding process of silicon materials, and the large depth of cut and rapid feed cannot be achieved. To achieve high-efficiency and high-quality processing, achieve high-efficiency precision grinding, and meet the requirements of high-efficiency and high-quality processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

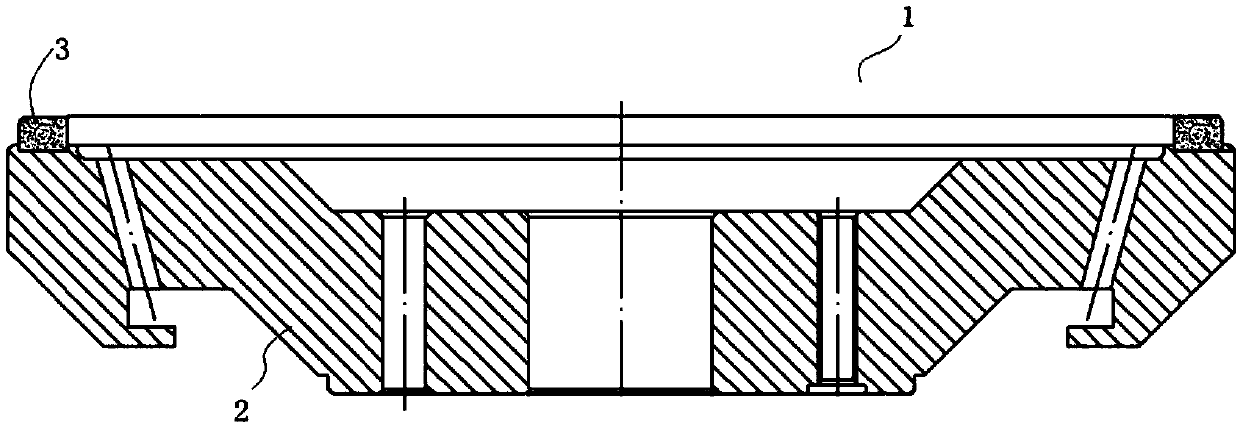

[0043] Example 1 of the preparation method of the non-dressing composite bond superhard grinding wheel for grinding silicon ingots of the present invention corresponds to the preparation of the composite bond superhard grinding wheel Example 1, and specifically adopts the following steps:

[0044] 1) Weigh the raw materials according to the formula and put them into a stainless steel tank, then place them on a planetary mixer, mix the materials at 300rpm for 45min, and get the preformed powder after mixing evenly;

[0045] 2) Put the preformed powder into the cavity of the graphite mould, spread the material evenly, press and form it on a sintering press with a pressure of 80kN, then raise the temperature to 380°C at a heating rate of 100°C / min, keep it warm for 45min, and then Furnace is cooled to room temperature, obtains grinding wheel blank;

[0046] 3) Bonding the grinding wheel blank to the aluminum alloy substrate, processing the substrate and grinding the grinding whee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com