Polylactic acid modified material for 3D printing, printing wire, and preparation methods of polylactic acid modified material and printing wire

A 3D printing and modified material technology, applied in the direction of additive processing, etc., can solve the problems of low impact strength, low glass transition temperature, and collapse of fine parts, and achieve the effect of low warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

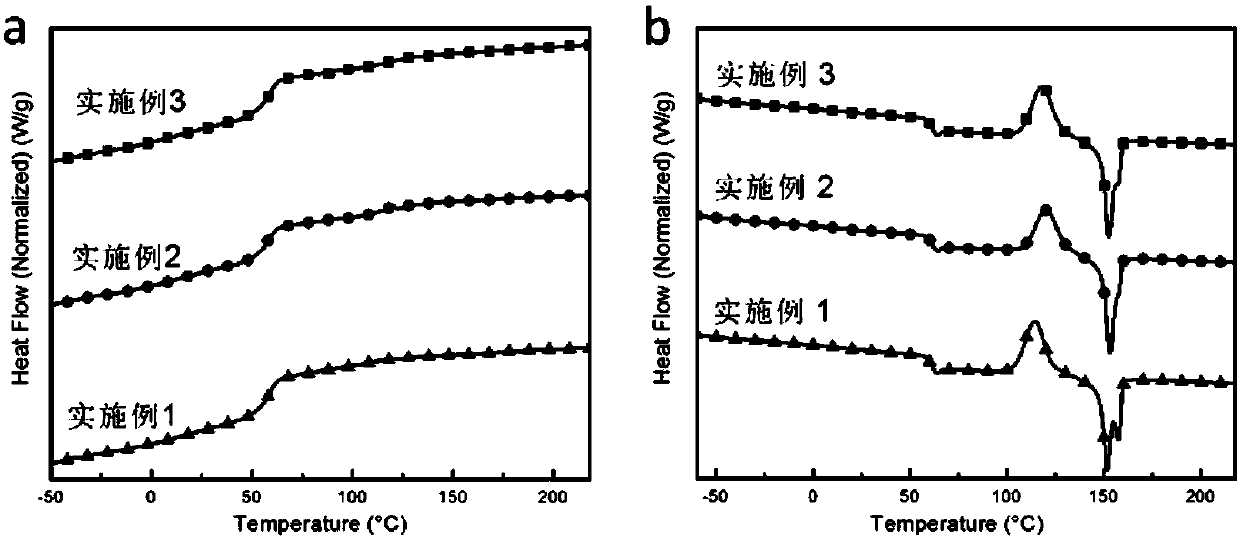

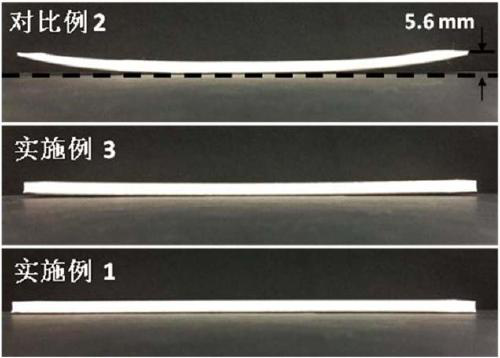

Embodiment 1

[0054] The polylactic acid (PLA) used in the present invention is produced by American NatureWorks LLC company, and the trade mark is IngeoTMPLA 4032D. Polycarbonate (PC) used in the present invention is produced by Saudi Basic Industries Corporation, and the trade mark is LEXAN TM Resin HF1130-111. Polybutylene adipate terephthalate (PBAT) is produced by BASF in Germany, the brand is F BX-7011. The three particles were first dried in a vacuum oven at 60°C for 4 hours to remove moisture. Finally, according to the mass parts of 70 parts of PLA, 27 parts of PC, and 3 parts of PBAT, manual stirring and mixing were carried out, and the mixing time was 20 minutes. PolyLab HAAKE Rheomex OS PTW16 co-rotating twin-screw extruder (screw diameter 16 mm, length-to-diameter ratio L / D=40) of American ThermoFisher Technology Co., Ltd. was used to extrude and granulate. The extruder has 11 sections from the feed port to the die, numbered 1-11, and the first section only plays the role o...

Embodiment 2

[0056]The PLA, PC and PBAT particles were first dried in a vacuum oven at 60°C for 4 hours to remove moisture. Finally, according to the mass parts of 60 parts of PLA, 38 parts of PC, and 2 parts of PBAT, manual stirring and mixing were carried out, and the mixing time was 20 minutes. PolyLab HAAKE Rheomex OS PTW16 co-rotating twin-screw extruder (screw diameter 16 mm, length-to-diameter ratio L / D=40) of American ThermoFisher Technology Co., Ltd. was used to extrude and granulate. The extruder has 11 sections from the feed port to the die, numbered 1-11, and the first section only plays the role of feeding and cannot be heated. The temperatures of sections 2-11 of the extruder are respectively: 210°C, 220°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C and 220°C, and the screw speed is set at 200 rpm. In steady operation, the torque is 40-60% of the maximum value. The extruder is equipped with a circular die with a diameter of 3mm. After the spline is extruded from the di...

Embodiment 3

[0058] Three kinds of particles of PLA, PC and PBAT were dried in a vacuum oven at 60°C for 4 hours in advance to remove moisture. Finally, according to the mass parts of 70 parts of PLA, 28.5 parts of PC, and 1.5 parts of PBAT, manual stirring and mixing were carried out, and the mixing time was 20 minutes. PolyLab HAAKE Rheomex OS PTW16 co-rotating twin-screw extruder (screw diameter 16 mm, length-to-diameter ratio L / D=40) of American ThermoFisher Technology Co., Ltd. was used to extrude and granulate. The extruder has 11 sections from the feed port to the die, numbered 1-11, and the first section only plays the role of feeding and cannot be heated. The temperatures of sections 2-11 of the extruder are respectively: 210°C, 220°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C, 230°C and 220°C, and the screw speed is set at 200 rpm. In steady operation, the torque is 40-60% of the maximum value. The extruder is equipped with a circular die with a diameter of 3mm. After the spline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com