Ultraviolet-curing resin composition and cured product thereof

A curable resin, ultraviolet technology, applied in the field of ultraviolet curable resin composition and its cured product, optical disc, can solve problems such as insufficient capacity, and achieve the effects of less warpage, excellent low water absorption, and good transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

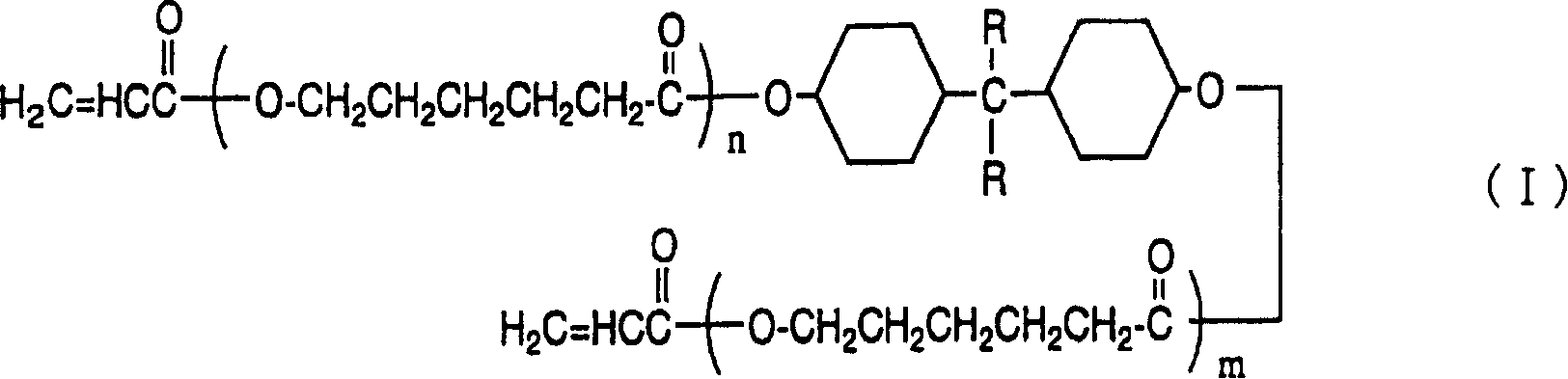

[0077] In the reactor equipped with reflux cooler, stirrer, thermometer, temperature regulator and water separator, put into the condensate 113.44g by hydrogenated bisphenol A and ε-caprolactone (molar ratio is 1: 1), acrylic acid 56.2g, sulfuric acid 2.8g, hydroquinone 0.84g, toluene 157.5g, cyclohexane 67.5g, at a reaction temperature of 95 to 105°C, the reaction was carried out while the water produced was removed by azeotropic distillation with the solvent. When the produced water reached 11 ml, it was regarded as the end point of the reaction. The reaction mixture was dissolved in a mixed solution of 140 g of toluene and 60 g of cyclohexane, neutralized with a 25% aqueous caustic soda solution, and washed three times with 50 g of 15% saline. The solvent was distilled off under reduced pressure to obtain 151 g of a transparent liquid represented by the following structural formula (A-1).

[0078] 【Chemical 4】

[0079]

Synthetic example 2

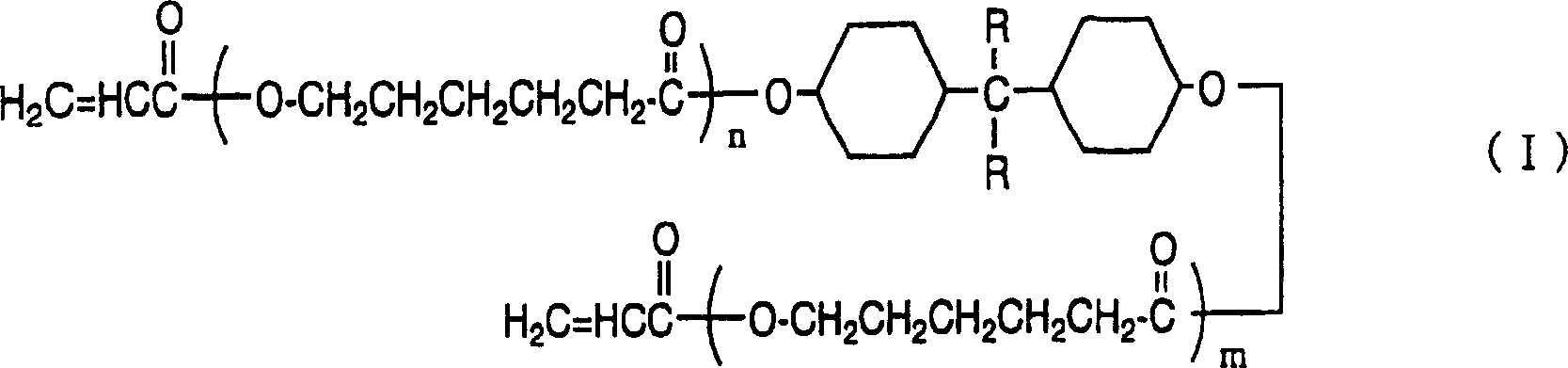

[0081] Equipped with the reactor of reflux cooler, stirrer, thermometer, temperature regulating device and water separator, put into by hydrogenated bisphenol A and ε-caprolactone (1: 2) condensation product 149.97g, acrylic acid 56.2g, Sulfuric acid 2.8g, hydroquinone 0.84g, toluene 157.5g, hexanaphthene 67.5g, under reaction temperature 95 to 105 ℃, make it react while removing the produced water by azeotropy with solvent, when produced water reaches 11ml was used as the end point of the reaction. The reaction mixture was dissolved in a mixed solution of 140 g of toluene and 60 g of cyclohexane, neutralized with a 25% aqueous caustic soda solution, and washed three times with 50 g of 15% saline. The solvent was distilled off under reduced pressure to obtain 186 g of a transparent liquid of the following structural formula (A-2).

[0082] 【Chemical 5】

[0083]

Synthetic example 3

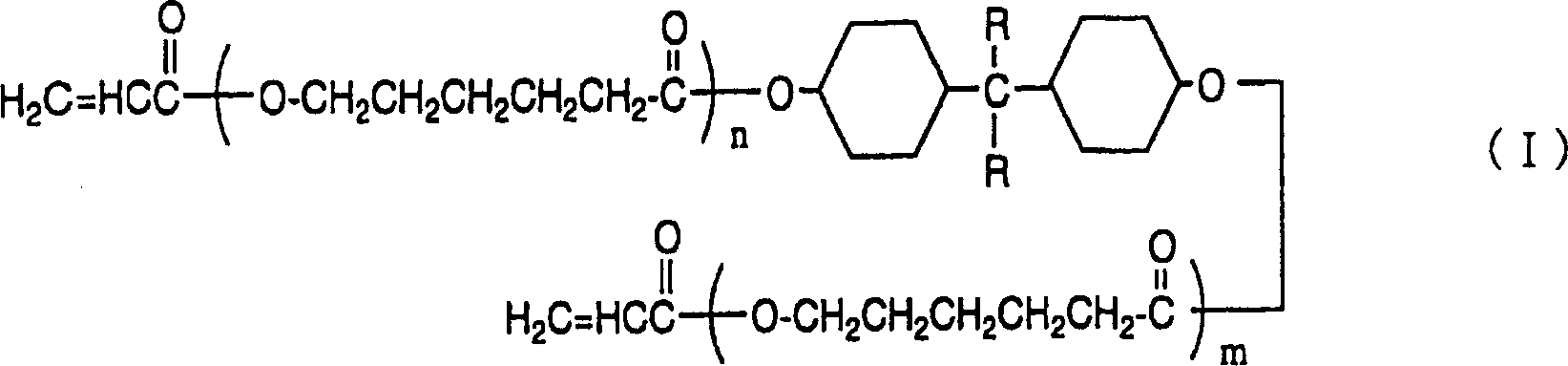

[0085] In the reactor equipped with reflux cooler, stirrer, thermometer, temperature regulating device and water separator, put condensate 141.01g by hydrogenated bisphenol F and ε-caprolactone (1:2), 56.2g of acrylic acid, Sulfuric acid 2.8g, hydroquinone 0.84g, toluene 157.5g, hexanaphthene 67.5g, under reaction temperature 95 to 105 ℃, react while removing the produced water by azeotropic distillation with solvent, when produced water reaches 11ml, then as the reaction end point. The reaction mixture was dissolved in 140 g of toluene and 60 g of cyclohexane, neutralized with a 25% aqueous caustic soda solution, and then washed three times with 50 g of 15% brine. The solvent was distilled off under reduced pressure to obtain 177 g of a transparent liquid represented by the following structural formula (A-3).

[0086] 【Chemical 6】

[0087]

[0088] (Example)

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com