superpixel-based copper surface defect detection method for a flexible IC packaging substrate

A technology for packaging substrates and defect detection, which is applied in the application field of image processing technology, and can solve the problems of high feature dimension, long time consumption, complex algorithm framework, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

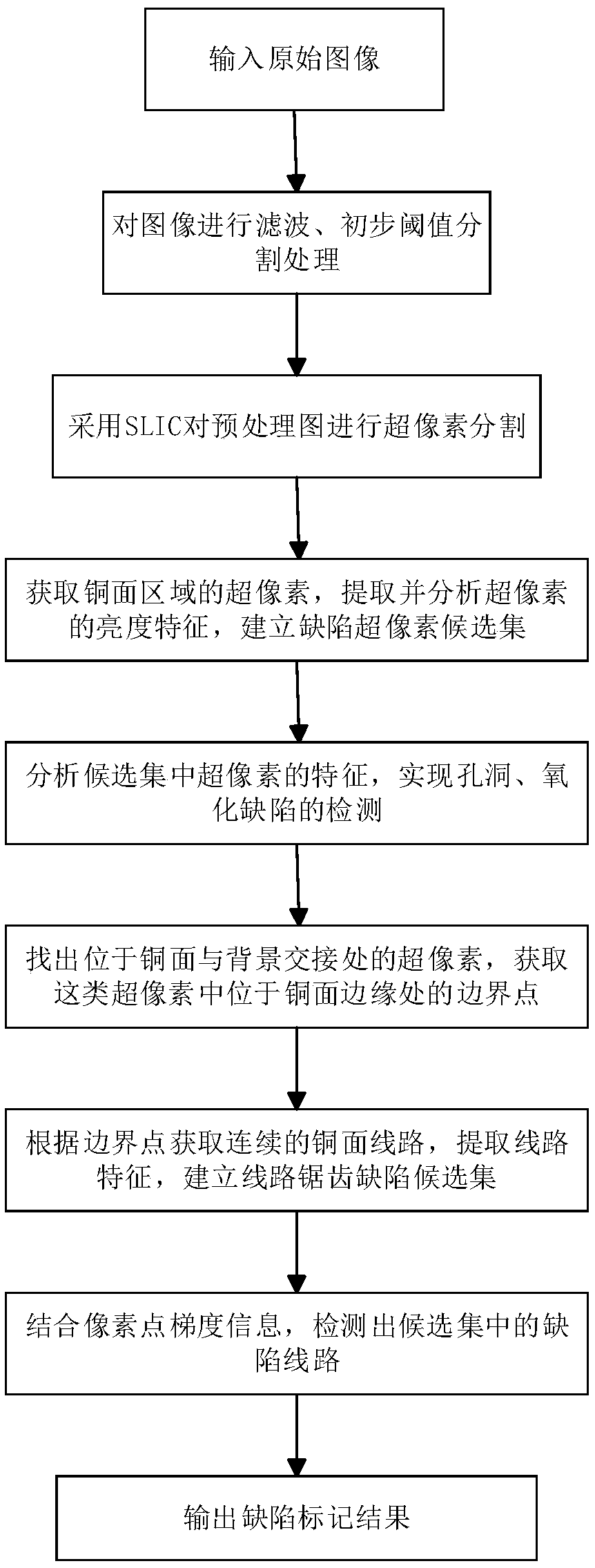

[0047] This embodiment discloses a method for detecting defects on a copper surface of a flexible IC packaging substrate based on superpixels, such as figure 1 — Figure 5 As shown, the steps are as follows:

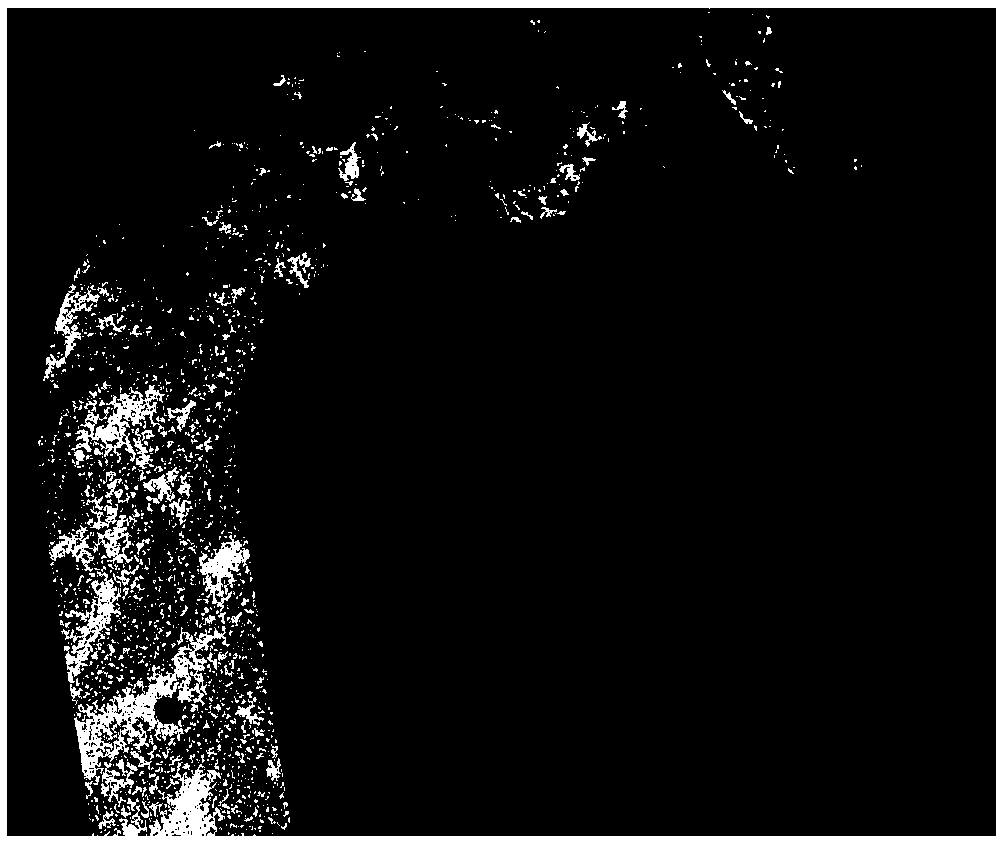

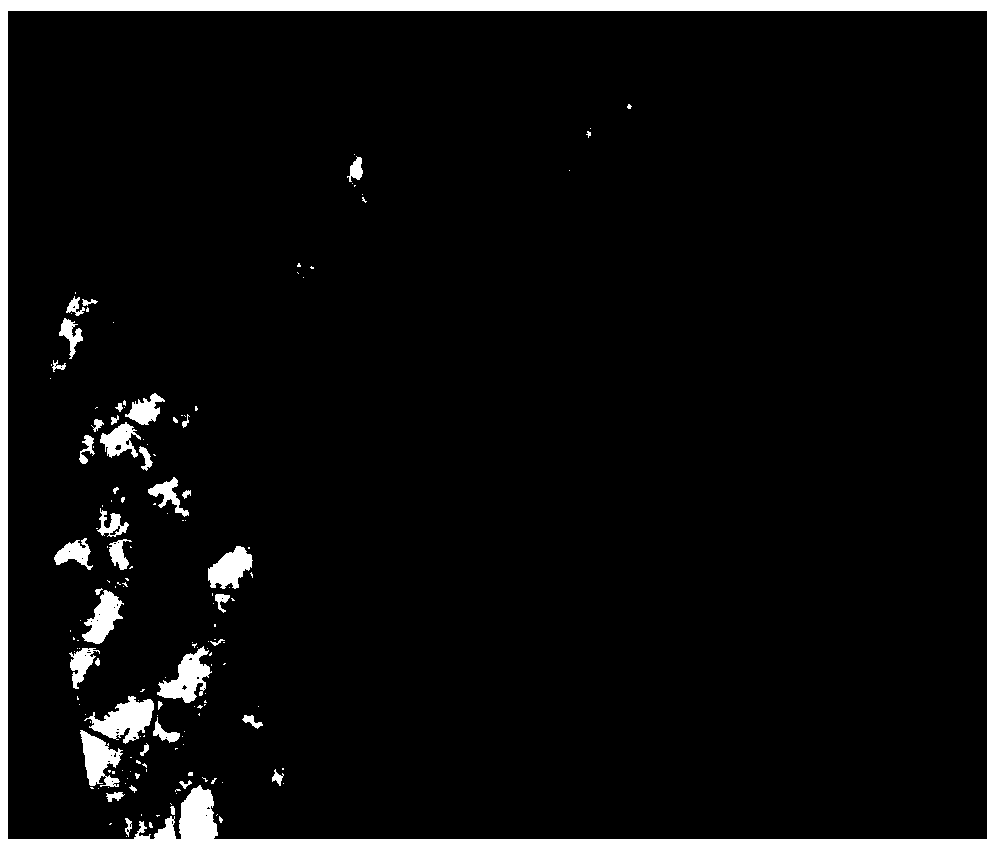

[0048] Step S1, first for figure 2 The original image of the flexible IC package substrate shown is filtered and preliminarily thresholded for segmentation, and then the simple linear iterative clustering method (SLIC) is used for superpixel segmentation to obtain a superpixel segmentation map;

[0049] Wherein in this embodiment, the specific process of preprocessing and superpixel segmentation of the flexible IC packaging substrate image in this step is as follows:

[0050] Step S11, first scale the original image according to a certain ratio, adjust the size N uniformly to 514×613, then use a Gaussian filter to eliminate image noise, use a bilateral filter to retain edge information, and reset the gray value to be smaller than the threshold T l0 The gray level of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com