Environment-friendly chemical conversion processing technology for aluminum alloy

A chemical conversion treatment, aluminum alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of difficult to meet the requirements of corrosion resistance and coating adhesion, high toxicity, environmental pollution, etc., to achieve easy storage and transportation, The effect of low cost and good coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

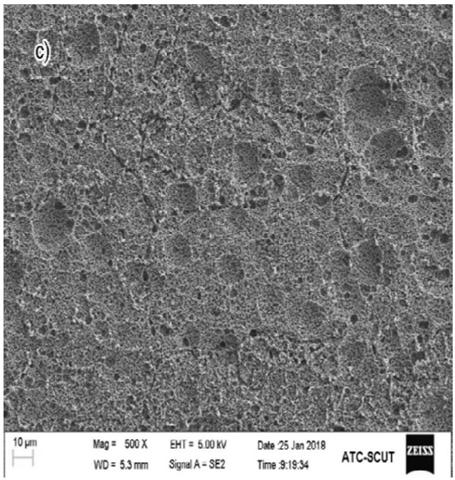

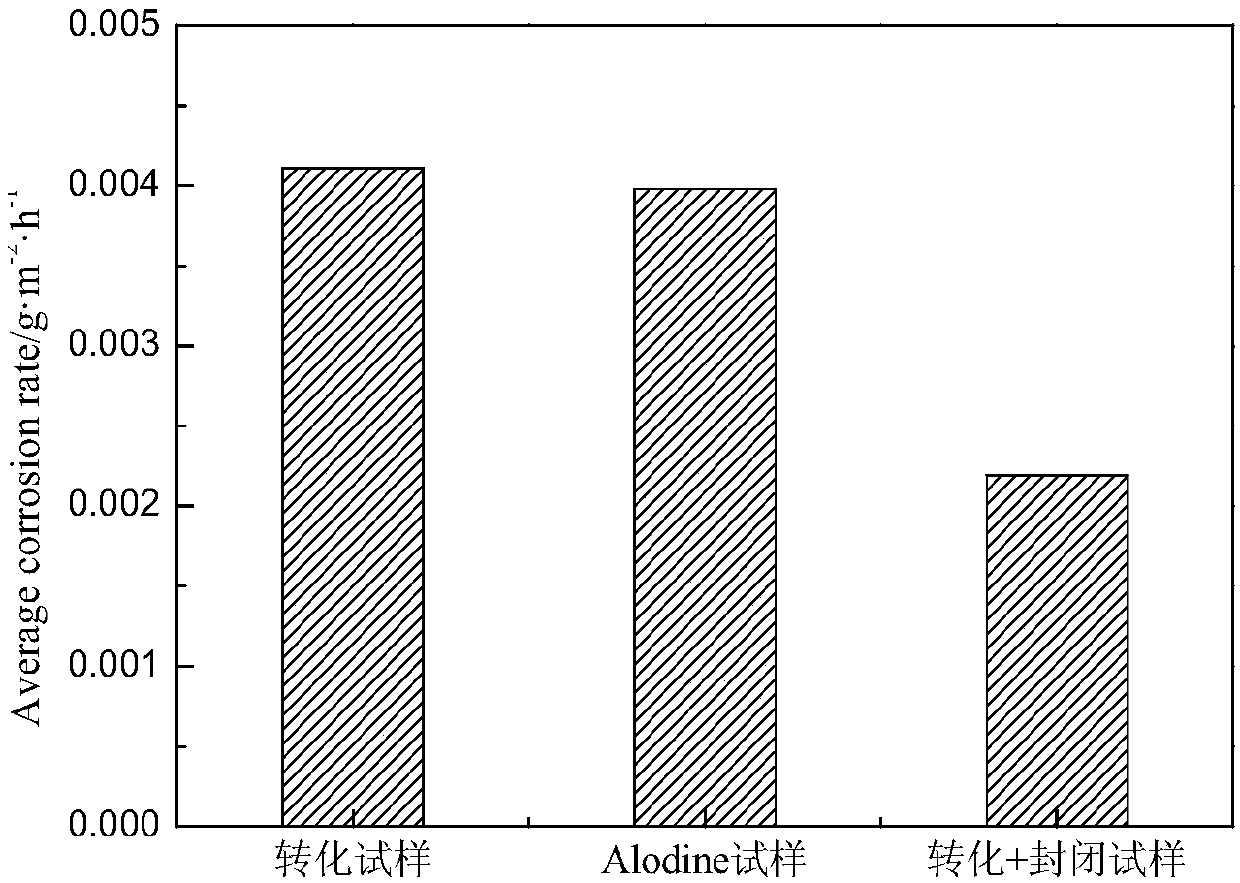

Image

Examples

Embodiment Construction

[0024] The present invention protects an aluminum alloy environment-friendly chemical conversion treatment technology, and its process steps for preparing a chemical conversion film are roughly as follows:

[0025] 1) Cleaning the aluminum alloy with water to remove surface dust attachments;

[0026] 2) Degreasing the aluminum alloy surface;

[0027] 3) Alkali etching treatment is carried out on the aluminum alloy that has been treated by degreasing to further remove the dirt on the surface of the product;

[0028] 4) pickling the aluminum alloy in the above steps to produce light;

[0029] 5) use the chemical conversion treatment solution of the present invention to perform conversion and film formation treatment;

[0030] 6) Finally, the surface of the aluminum alloy in the above steps is sealed;

[0031] 7) Rinse the aluminum alloy with water and let it dry naturally.

[0032] Specifically, the pretreated aluminum alloy workpiece is first cleaned with tap water or disti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com