Groundwater in-situ chemical oxidation remediation method and remediation device

An in-situ chemical oxidation and repair method technology, which is applied in the field of groundwater in-situ chemical oxidation repair methods and repair devices, can solve the problems of difficult control of chemical dosage, easy to cause danger, affecting treatment effect, etc., and achieve controllable injected chemical dosage. , safe operation, convenient and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

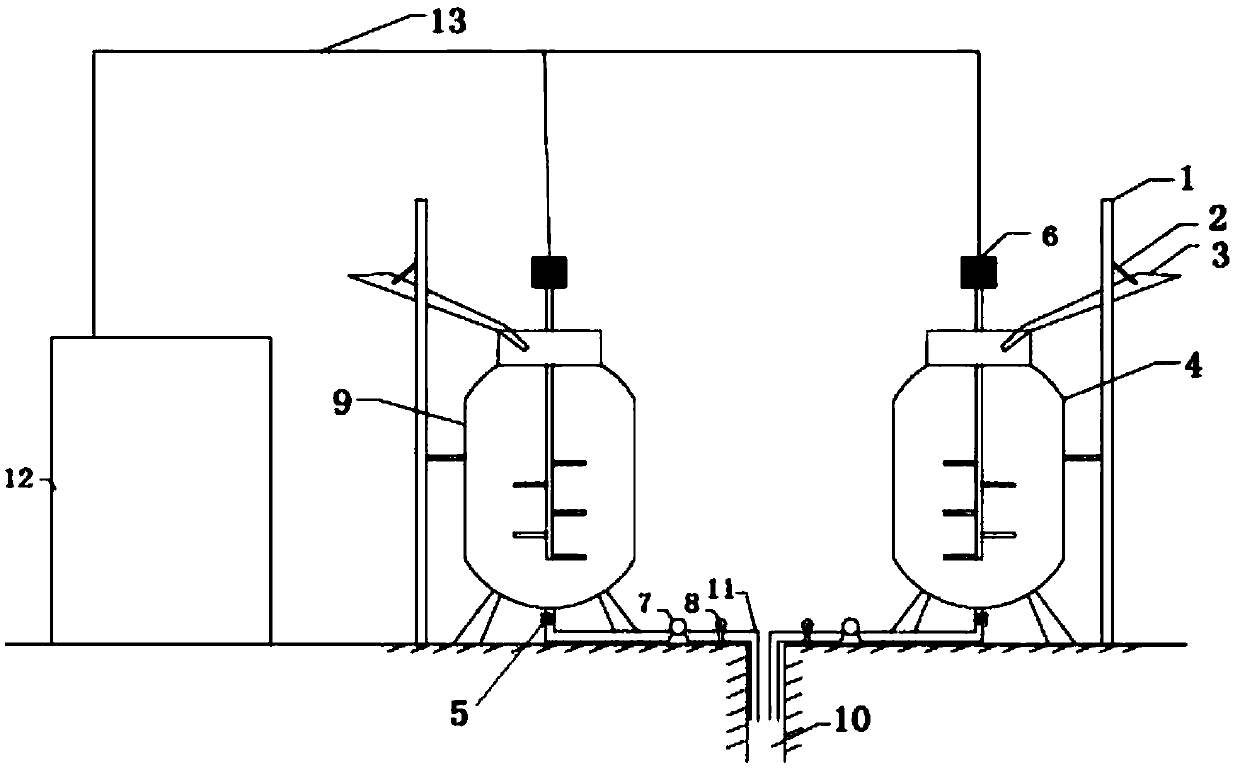

Embodiment 1

[0040] Weigh an appropriate amount of sodium persulfate and sodium hydroxide solids, and put them into the horizontal dosing tank respectively. The dosing tank is equipped with a cover, and the dosing tank is adjusted to reduce from 180° to 145°, so that the medicine is automatically injected with the change of the inclination angle. In the dispensing tank, after the solid medicament is put in, add water to prepare the oxidizing agent sodium persulfate into an oxidizing agent solution with a mass concentration of 1.00%, and prepare the catalytic agent sodium hydroxide into a catalytic agent solution with a mass concentration of 0.5%. At the same time, the stirring device, Its operating speed is 45r / min, and the medicine is completely dissolved after stirring for 10 minutes; the flow control valve 8 is adjusted so that the output flow rate of the sodium persulfate medicine is 1.2m 3 / h, the output flow of sodium hydroxide catalyst is 1m 3 / h, turn on the pressure pump of the ox...

Embodiment 2

[0042]Weigh an appropriate amount of sodium persulfate and sodium hydroxide solids, and put them into the horizontal dosing tank respectively. The dosing tank is equipped with a cover, and the dosing tank is adjusted to reduce from 180° to 145°, so that the medicine is automatically injected with the change of the inclination angle. In the dispensing tank, after the solid medicament is put in, add water to prepare the oxidizing agent sodium persulfate into an oxidizing agent solution with a mass concentration of 1.5%, and prepare the catalytic agent sodium hydroxide into a catalytic agent solution with a mass concentration of 0.5%. At the same time, the stirring device, Its operating speed is 45r / min, and the medicine is completely dissolved after stirring for 10 minutes; the flow control valve 8 is adjusted so that the output flow rate of the sodium persulfate medicine is 1.2m 3 / h, the output flow of sodium hydroxide catalyst is 1m 3 / h, turn on the pressure pump of the oxid...

Embodiment 3

[0044] Weigh an appropriate amount of sodium persulfate and sodium hydroxide solids, and put them into the horizontal dosing tank respectively. The dosing tank is equipped with a cover, and the dosing tank is adjusted to reduce from 180° to 145°, so that the medicine is automatically injected with the change of the inclination angle. In the dispensing tank, after the solid medicament is put in, water is added to prepare the oxidizing agent sodium persulfate into an oxidizing agent solution with a mass concentration of 4.00%, and the catalytic agent sodium hydroxide is prepared into a catalytic agent solution with a mass concentration of 0.5%. At the same time, the stirring device, Its operating speed is 45r / min, and the medicine is completely dissolved after stirring for 10 minutes; the flow control valve 8 is adjusted so that the output flow rate of the sodium persulfate medicine is 1.2m 3 / h, the output flow of sodium hydroxide catalyst is 1m 3 / h, turn on the pressure pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com